There’s nothing more satisfying than capping a pleasant day on the water with a good meal, be it burgers and dogs on the grill or some fancy, culinary extravaganza whipped up by the galley wizard. Most marine stoves and grills use liquefied petroleum gas (LPG). It’s efficient, relatively cheap, and widely available. Its also highly explosive-particularly with regards to boat installations-which makes proper installation and regular inspection so critical in onboard systems.

LPG, a combination of propane and butane, is a gas that changes to a liquid form when pressurized, a trait that allows for easy storage in its concentrated, liquid form. Once this pressure is removed, it changes back into a gas for use in stoves, grills, and the like.

One downside of LPG is that it’s heavier than air, which means it tends to “flow” like water, seeking the lowest possible point. This typically isn’t a problem with shore installations, as there tends to be more airflow to help disperse leaking gas; however, boat installations are another matter. A boat’s hull is essentially a watertight envelope, meaning explosive gases can be trapped in bilges or other low areas, where they can rapidly accumulate to explosive concentrations. LPG suppliers are required by law to add an odorant in order to make leaks more noticeable, but just because you can’t smell gas doesn’t mean it isn’t there; the gas can remain after the odorant has dissipated.

The goal of any LPG system inspection is to prevent (or locate) gas leaks. In this article, we’ll cover basic LPG system installations and inspections, however always seek professional advice from a certified LPG installer if you’re unsure about any aspect of inspecting or maintaining your LPG system.

Fuel Cylinders and Storage

All LPG cylinders must meet Department of Transportation (DOT) or American Society of Mechanical Engineers (ASME) requirements. You can verify whether a tank is acceptable by looking for a stamp from one of these organizations near the tank valve. LPG storage tanks can be mounted on deck or in a dedicated storage locker; however, they must be properly secured in an upright or horizontal position, depending on the design of the tank.

Tanks designed to be mounted vertically should never be installed in a horizontal position, which could allow liquid LPG to flow through the regulator and into the system, causing flare-ups and all manner of nasty things. The above applies to all tanks, regardless of their status (full, empty, disconnected reserve cylinders, etc.).

Cylinders mounted on deck have to be located in a well-ventilated area where leaking gas will flow directly overboard; they must be readily accessible and be protected against weather and/or mechanical damage. The aft portion of the vessel is typically better in this regard, as tanks will be less exposed to saltwater spray and its corrosive effects.

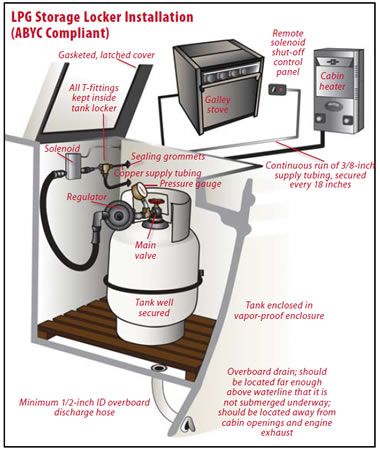

According to the American Boat and Yacht Council (ABYC), dedicated LPG storage lockers must be vapor tight to the vessel’s interior, located above the waterline, and be constructed of or lined with corrosion-resistant materials. Check that your locker has a gasketed cover that latches tightly, opens only from the top, and can be quickly opened without tools, so you can easily access the tank shutoff valve during an emergency.

LPG lockers are required to open directly to open air. However, an after-market, standalone locker like those Trident Marine sells can be located inside a cockpit locker if they are mounted so that the LPG locker lid can’t be opened without opening the cockpit locker first. All LPG lockers must also have a dedicated drain at the bottom that vents directly overboard; the drain must be a minimum of a half-inch in diameter.

An LPG locker must be a dedicated space. That means all non-LPG system items—shackles, tools, etc.—must be removed as they can easily damage system components. When inspecting the locker, check the bottom, sides, and seams for damage (corrosion, cracks, holes) that could allow gas leaks into the boat interior.

For internal lockers, ensure the locker vent hose slopes downward and is free of blockages, loops, and kinks. The discharge outlet must be located below the locker and must exit the hull above the static waterline, at least 20 inches away from any other opening (air intakes, sink or bilge pump discharges, engine exhaust, etc.) that could allow gas to re-enter the hull.

A note of caution about external, stern-rail mounted LPG lockers: Most stern rails are not designed to withstand the loads induced by waves breaking over the external locker, so storing your LPG tank on the stern rail runs the risk of losing the rail in foul weather.

Shut-Off Valves

Every LPG system is required to have a readily accessible manual or electrically operated (e.g., solenoid) shut-off valve installed in either the low- or high-pressure line at the cylinder. Check that the valve or solenoid remote control is located in the vicinity of the appliance it serves and is mounted so you can operate it without reaching over the top of any open flame (such as a stove burner).

For a corrosion-resistant solenoid valve, David Anderson of Sure Marine Service, recommends using one made of marine-grade stainless steel. He said that the common cadmium-plated steel solenoids will rust in short order on a boat.

Fuel Lines

Copper hose is used throughout the world in most LPG installations, but flexible, high-pressure hose is another option worth considering. Both types have their pros and cons: Flexible hose allows for gimballing stoves and resists vibration better than copper, but copper withstands chafing (and rat gnawing, see sidebar) better than flexible hose. Installations that use flexible hose should include chafe protection.

Whether you use copper or flexible hose, it’s imperative that you visually inspect lines for cracks, brittleness, kinks and chafing, ensuring each is protected by grommets at bulkheads, partitions or deck penetrations. For copper lines, in addition to chafe protection, verify that all fittings are long nut-flare fittings; short nut fittings (such as those used in refrigeration systems) are less reliable and prone to failure due to vibration.

Check the outer jacket of flexible hose for markings that indicate compliance with Underwriters Laboratory UL21 LP Gas Hose. Verify that all end fittings are permanent types such as a swaged sleeve or sleeve and threaded insert; hose clamp fittings are a big no-no.

Finally, each appliance (galley stove, cockpit grill, etc.) has to have its own dedicated supply line, with each one originating from inside the propane locker or tank enclosure at the solenoid valve. The supply line must be a continuous run, with no breaks, connections, or Ts in order to reduce the possibility of leaks.

Regulators, Gauges, Leak Tests

Every LPG system has to have a pressure regulator designed for use with LPG. For deck-mounted cylinders, verify that the regulator’s relief valve outlet discharges outside the boat at least 20 inches from any hull opening (just like the locker discharge).

LPG systems are also required to have a pressure gauge installed on the cylinder side of the pressure regulator. This gauge allows you to quickly and easily check the system for leaks using a leak down test. To conduct a leak down test, turn on an LPG appliance (the stove or grill), then close all the burner valves but leave the solenoid switch on. Note the pressure gauge reading, then close the tank valve. The gauge reading should remain constant for at least three minutes. If the pressure drops, then you have a leak (or leaks) and you must inspect the entire system before using any connected appliance.

Check your LPG system regularly for leaks or anytime you fire up that stove or grill. Leaks can occur anywhere in the system due to chafe or physical damage to supply lines or other components, but they typically occur at fittings and connections. To locate leaks in the system, you can use leak detection fluid or concoct a detergent-water solution. Liquid dishwashing soap mixed with water will produce the most bubbles. Don’t use solutions containing ammonia, which will attack brass fittings, and unless you want top billing at the Darwin Awards, never use a flame to check for LPG leaks.

Mix the soap-water solution in a spray bottle and stream spray (don’t mist) it onto hoses, connections, and other parts of the system. You can also use a sponge or rag to apply the solution, but we’ve found a spray bottle to be fastest, and it can get to hard-to-reach places. If you see bubbles, there’s a leak.

Installation of a marine-grade LPG sniffer or fume detector is also highly recommended. If you have one installed, be sure that the gas sensor is mounted as low as possible and near the range (where leaking gas is likely to accumulate) and that you test sensor operation on a regular basis. Other desirable safety upgrades include installing smoke and carbon-monoxide detectors.

Best practices when cooking with LPG is to leave one burner ignited after cooking and turn off the solenoid or tank valve. When the flame goes out, close the burner valve; this empties the line of gas and prevents leaking should a burner valve fail to seal. It’s also a good idea to close the LPG tank valve in addition to the solenoid valve when the system is not in use, particularly if you plan on leaving the boat for an extended period of time. (The solenoid should always be closed when the system is not in use.)

Whether you’re installing an onboard LPG system for the first time or preparing for your regular inspection, here are some tips and reminders to help ensure it’s done right.

Tape, Thread Sealant, or au Natural?

In addition to the specialty fitting used at the tank, typical marine LPG system connectors include quarter-inch or 3/8-inch national pipe thread (NPT) and/or 45-degree SAE flare connections (male and female). Only NPT fittings require the use of Teflon (PTFE) tape or thread sealant (aka pipe dope) on the threads; SAE flare connections are self-sealing.

Either Teflon tape or thread sealant will work fine, so choosing which one to use boils down to personal choice. But just use one, not both—using both is counterproductive and not recommended—and be sure to follow the manufacturer’s instructions.

The yellow variety of Teflon tape is specifically designed for LPG systems; it’s thicker and more durable than the white PTFE tape, which is normally used for water pipe joints.

When applying Teflon tape, wrap three or four layers around the connector threads, avoiding any tape overlap at the end of the hose, which could come loose and cause clogging issues in the system. Next, insert the fitting and twist until hand tight, then snug it up with a wrench, but don’t over-tighten (which can damage both fitting and threads). Finally, test the fitting for leaks using leak detection fluid or the DIY water-soap solution. If leaks are found, try gently tightening the fitting a bit and retesting. If it still leaks, replace the fittings and try again until all leaks are fixed.

Tips for Safe Grilling

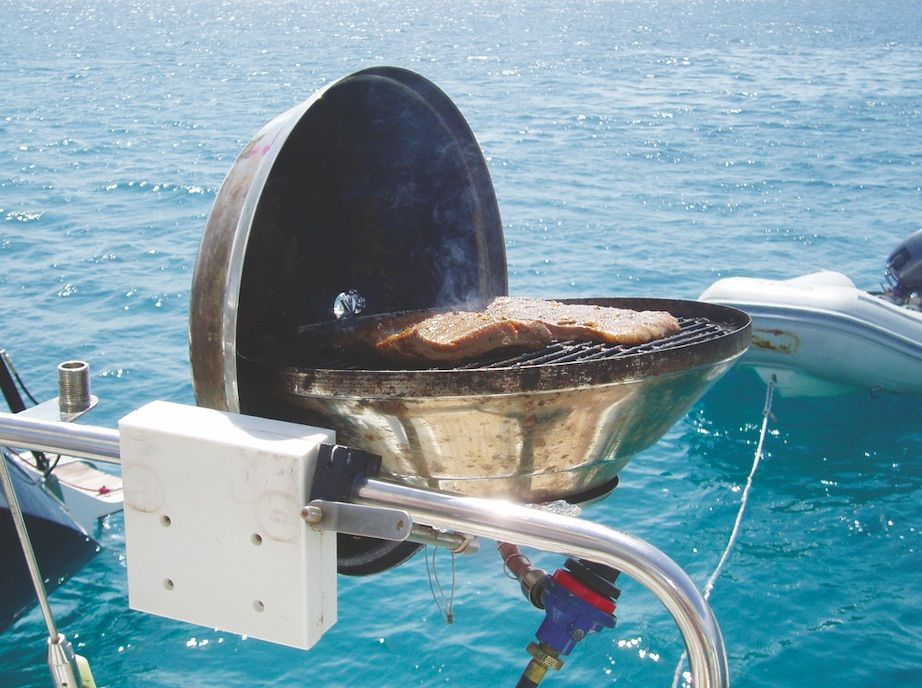

Because grills are located above decks, boaters tend to treat them with a more cavalier safety attitude than galley ranges—bad idea. According to the Insurance Information Institute, each year, grills cause more than 2,000 fires, over 300 related injuries, and at least three deaths. Here are a few tips on how to avoid becoming a barbecue statistic.

- Make sure your grill is mounted securely and in accordance with the manufacturer’s instructions. Avoid using camp-type grills on a boat; they typically have no means to be properly mounted.

- As with your galley stove, grill burner controls should have two-stage operation when going from “off” to “on” to prevent accidentally opening the valve during handling or storage, and the controls should be located at the front of the grill so you can operate them without reaching over the burner.

- If your grill is fueled by an LPG system, inspect the system frequently. If it uses portable gas cylinders, they must be DOT-approved 2P/2Q 8-ounce units with rim vent releases.

At 6:30 a.m. Jan. 2, 2014, an explosion aboard a sailboat rocked the docks at the Vista Rio Hotel and Marina in Rio Dulce, Livingston, Izabal, Guatemala. Marine surveyor Capt. John Brandes (www.riodulcesurveyors.com), who was on the scene, supplied PS with the accompanying photos and details of the propane-related explosion.

According to Brandes, the destroyed boat was an older 37-foot Hunter, Panacea, that was owned by a Swedish native. The owner had been complaining of a rat problem, and it seems that overnight, a rat chewed a hole in a flexible hose in the propane supply line. When the owner lit a cigarette in the morning, it ignited an explosion that decimated the boat, fatally injured the owner, and damaged two neighboring boats.

The LPG-fueled stove, LPG tank, and supply hoses were later recovered from the wreckage. It was obvious that the system was an aftermarket, DIY setup that ignored ABYC safety standards. Brandes reported that the tank had no remote shutoff valve and that it was found with the valve open and almost empty, but it still had a little gas remaining that was flowing from the hose.

In May 2013, the U.S. Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA) issued the emergency recall of 55,000 fiber-composite propane tanks manufactured by the Lite Cylinder Co., requiring that they be removed from service and terminating Lite Cylinder’s authority to re-qualify and manufacture DOT cylinders. The recall was issued after an investigation of the manufacturing site revealed unsafe conditions and practices. (We covered the recall in the August 2013 Mailport, but you can also find more information about it on the PHMSA website, www.phmsa.dot.gov).

Practical Sailor received a report of a cracked Ragasco gas cylinder that was sold to one of our readers in 2010. Such instances emphasize the need to regularly inspect ALL tanks—regardless of construction materials or age—and have each pressure tested at the required intervals. Things to look for during your routine tank inspections include rust or corrosion, leaks, bulges, gouges, dents, defective valves, damage to the foot ring, collar, or protective ring, and of course, evidence of heat or fire damage.

Depending on cylinder specifications and the requalification method used, LPG tanks must be inspected and tested every five, seven or 12 years. Composite cylinders have a 15- year service life and require requalification by visual inspection and pressure testing every five years.

This article was originally published on 13 February 2014 and has been updated.

Thank you very much indeed for sharing this important information with us. It helped me to stay safe when installing and handling a propane tank. Thanks for sharing the post with us.

I sailed 20 years in the Florida Keys the Bahamas and Virgin Islands. The number one safety rule I followed was have valves closed at all times when not in use!!!!When I’d cook on the galley stove I’d open the tank valve and do my cooking. When done I’d leave the stove lit and go turn the tank valve off first and let the stove burn till it used the gas in the line. After the flame goes out close the stove valve off. Therefore never worry about leaks while enjoying the freedom of self cruising

If you don’t turn off the tank before shutting off a propane outboard, will the propane left in the hose cause a clogging problem? How can I fix a clogged propane hose for an outboard?

Thanks for sharing that vertical tanks should never be installed horizontally. That is something that I feel can be easily avoided. But it all depends on what the installers try to do.

Some multihulls use propane refrigeration, similar to RV’s. I understand Gemini catamarans had propane refrigeration installed for many years. Since these systems must have the propane supply turned on continuously, how can they be in compliance with the regulations you mention here? What is known about the safety record of these systems?

I am curious about the “gasketed” latched cover. To properly vent any container there needs to be access for air to enter the container at the top in order for the fluid/gas that is heavier than air to flow out the bottom. By having the locker sealed with a gasket, it seems we reduce the capacity for the locker to be properly vented of the LP gas. Any other thoughts on this?

Carry plenty of booze, eat ashore. Solved gas problems and helps local economy

Many who eat ashore have had significant problems with gas and valves.

Do you have data to support your claim that you can still have LPG present even after the methyl mercaptan odor is gone? You may be aware that the human nose can detect this as low as 10 ppb.

Speaking on behalf of the rat afloat in figure 3 – s/he could have been an innocent bystander just looking out for their unfortunate pal who, as they say, bit the big one…

😉

(sorry, could not resist)

Good article – thanks!

Another boat owner told our owners’ group that he discovered his LPG hose at the stove wien almost to the point of leaking. His pictures looked exactly like the one shown in the sidebar. No Rats! It was caused by leaving the stove gimbaled all the time and chafing the hose against the hull. I would guess that a rat would make a hole much more jagged than this one.

I checked mine to find only minor chafing, but replaced it with a metal-clad hose, and only gimbal the stove when in use.

Due to the high volatility of propane, I went back to the basics. I found and use a Swedish made Punker brand, stainless steel two burner liquid alcohol stove. I figure I can outrun a fire, an explosion, not so much.

Every propane installation I have seen includes a small pressure gage mounted just after the tank. The pressure gage is not useful in determining how much gas is left, but is valuable as a leak tester.

Turn off the stove, but leave the solenoid on. Close the gas bottle valve. The pressure gage should show that pressure is maintained. If it does not, there is a leak.

I have a 10lb Aluminum horizontal cylinder in pristine condition. It is past its certification date. I am having great trouble finding anyone (Rhode Island or thereabouts) to inspect and recertify it (if it passes). Do you know how I can get this done?

Chad Rider