It has been almost 10 years since Practical Sailor weighed in specifically on mainsail track hardware (see Practical Sailor, Feb. 1, 2005 online). At the time, we offered a summary of the products designed to manage what we termed the three Ss of mainsail handling-setting, shortening, and striking. In that article, we focused on the gear used with full-battened mainsails, which were becoming increasingly popular among a broad spectrum of sailboat owners then.

Ten years ago, we cautioned readers that on a modern sailboat, handling the mainsail quickly and surely is … important, both as a safety measure and a matter of convenience. Of course, that hasn’t changed over the ensuing decade, and neither has the essential nature of this equipment. What we wrote then still applies: Low-friction systems designed and built to handle the loads generated by full battens under pressure fall into two basic categories: those that use a dedicated track attached to the mast and those that utilize a slide or car fitted for the existing groove in the spar.

Though at least one new product line for taming mainsail luffs has been introduced since we published that evaluation-Karvers KMS cars-there hasn’t been significant evolution in this realm. Other than advances in the batten end connectors, the mainsail tracks, cars, and slides used today are much the same as they were 10 years ago. Nonetheless, it’s important for Practical Sailor to offer an overview of available options, along with some valuable advice that might particularly benefit those owners who struggle with less than efficient mainsail luff systems.

The Survey

In order to get a grasp on the products that work best-and to garner useful advice-we surveyed a cadre of sailmakers representing the larger, more established firms in this field to understand their recommendations for existing options. To allow for varying sailing conditions, we purposely checked in with sailmakers in a variety of regions across the U.S., including the Northeast, the Southeast, the Gulf Coast, the West Coast, and the Midwest.

And, to provide these respondents with some structure for their answers, we contrived two sample scenarios and asked them to advise the boat owner in each. The first scenario involves a Hunter 27 whose mainsail has only partial battens and whose owner would like to more efficiently raise, reef, and lower the mainsail. (Since a majority of boats from Hunter-Marlow Marine are now sold with in-mast furling, we stipulated that this was an older model with a mast groove and slides on the luff.) For the second scenario, we postulated that the owner of a Bavaria 50 had recently moved to a full-battened mainsail and wanted to improve the efficiency of the mainsail luff system.

The Experts Weigh In

Like the majority of the sailmakers we spoke to, Joe Cooper, a 40-year veteran racing sailor and sailmaker who now works as a consultant for Hood Sails in Middletown, R.I., had questions of his own:

“My immediate response is what kind of sailing does the customer plan to do?,” asked Cooper. “From a sailmakers perspective, you really have to understand what the guy wants to do with his boat, and that may evolve. And, depending upon the boat and the setup, there are things he can do to improve efficiency that don’t rise to the level of replacing the luff slide/car system.”

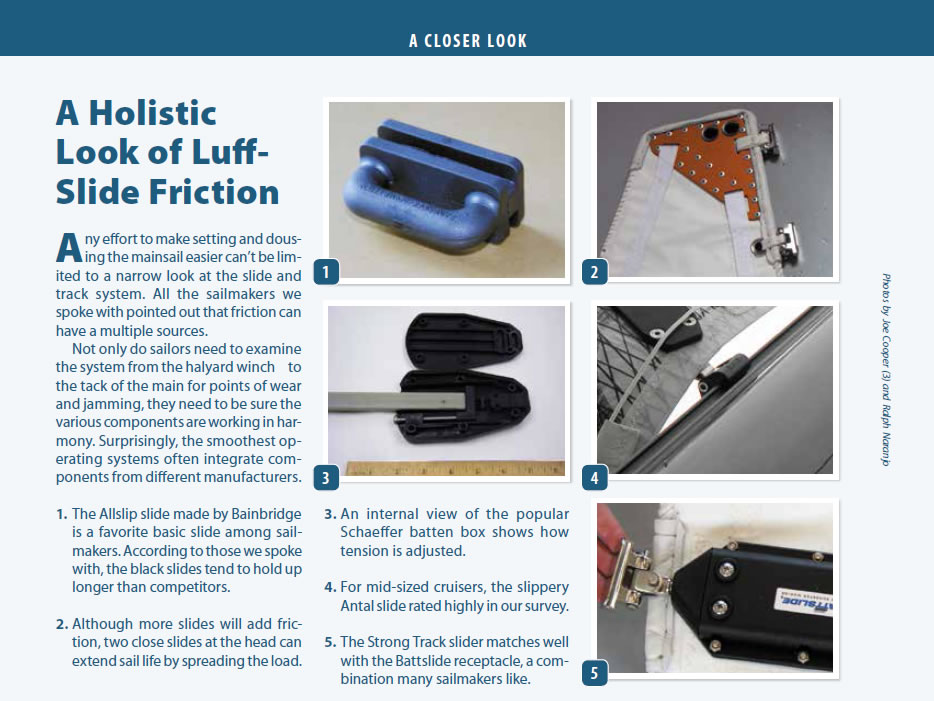

According to Cooper, almost everyone jumps to the conclusion that the best fix is upgrading the luff-slide system for more friction-free sailhandling. He said that our hypothetical Hunter owner will want to take a close look at the halyard itself and the mast sheaves-in fact, he should check anywhere that halyard friction might come into play.

Cooper said that where possible, a helpful upgrade would be to increase the sheave diameter at the masthead and at all turning blocks. Reducing the halyard line diameter by switching to a smaller, less stretchy halyard can also help. [As we pointed out in our review of rope clutches (see Practical Sailor November 2014 online), there can be some hidden expenses to such an upgrade if the reduction is too great.]

Cooper’s improvements point to a common shortfall in halyard handling systems on many production boats. Cordage specialists tell me that you need an 8:1 ratio between the sheave and the line, Cooper said. That means that if you have half-inch-diameter line, you should ideally have a 4-inch diameter sheave. The sheaves at the masthead, the base of the mast, and everywhere a main halyard turns are all candidates for upgrades. This is one of the most cost-effective things you can do.

Cooper explained that the slides or cars are one of 10 things in the equation that can affect how easy it is to set and douse the mainsail. It’s pretty clear that if you don’t have a holistic approach to this issue, you’re not going to end up with the best solution, he said.

In the San Francisco Bay area, Ben Mercer is the service technician at Quantum Sail Design Groups Point Richmond loft. A 12-year industry veteran, Mercer offered specific gear suggestions, advice we heard from several other sailmakers we spoke with. His initial recommendation as an option was a Tides Marine Strong Track. Described in our article on upgrading the cruising mainsail (see Practical Sailor August 2011 online), the strong track is a single length of low-friction, ultra-high molecular weight polyethylene plastic (UHMPE) that is machined to slide onto your existing mast track. The product is sold by the foot, and comes with user-selected batten boxes and slides.

One key advantage to the Strong Track, Mercer explained, is that you get a custom fit no matter what kind of mast you have. It doesn’t matter whether its external track or an internal groove. Among our customers, its a very popular system. Weve recommended them for singlehanded boats that are sailing to Hawaii in the Single Handed TransPac.

Tides Marine, maker of the Strong Track, offers plenty of pre-purchase guidance on its website. The company points out that not every boat is a contender for this system, and advises buyers to consult them before jumping in. Recommended sail area tops out at around 650 square feet (600 square feet for multihulls), and fully-battened sails with a lot of roach deserve special consideration, as they can put excessive loads on the hardware. The tracks are not recommended for storm trysails.

The feedback that we get on the Tides Marine systems is very positive, Mercer said. People always cite the ease of use, the lack of maintenance needed, and the fact that the owner can often carry out the installation himself pretty easily.

Mercer said that although bearing-loaded track and car systems designed by Antal and Harken might be more durable and smoother under heavier loads, they are much more expensive. A key benefit is that this system comes at roughly half the cost of installing an Antal track or a Harken track. Those tracks and cars/slides work really well, but the price difference is significant.

At the more economical end of the spectrum, Mercer advises his smaller boat customers with integral mast tracks to consider upgrading to Allslip Slides, which are precision molded from fiberglass-reinforced plastic impregnated with slippery polytetrafluoroethylene (PTFE, or Teflon). These slides were universally recommended by the sailmakers we surveyed.

The only time that our recommendations are partial to a particular slide is in the case of the Allslip, Mercer said. If the customer doesn’t want to change out the track, then we try to put the focus on the Allslip slides, especially out here in the Bay Area because of the conditions that are prevalent.

Mercer said that in his experience, the Allslip slides have a greater longevity and seem to operate a little easier than the flat plastic slides from other manufacturers, even though they may look very similar.

For owners of larger boats-particularly those for whom cost isn’t a primary concern-Mercer recommends Antal’s track and slide system, which uses cars riding on composite inserts over an aluminum track. This system is preferred for many carbon-fiber masts and offshore spars, he explained. The slides have replaceable inserts that operate in essentially the same way as the Tides Marine system.

When it comes to a heavily loaded batten system, Mercer prefers ball-bearing car systems such as those by Harken, Ronstan, Rutgerson, and Selden. Which system you choose is often dictated by the mast track already in place.

Although early versions of these track-and-car systems created headaches for owners who had to deal with routine bearing replacement, more recent developments have made this task easier. The majority of these companies have resolved the challenge of changing out those bearings by introducing captive bearing systems, Mercer said. Nevertheless, it is always a good idea to have a section of track, loader, or bucket handy to remove cars.

One recurring problem that Mercer has seen is decay caused by airborne pollution. He said boats that are kept in marinas near bridges or roads are exposed to airborne pollutants that can take a toll on mast-and-car systems.

Photos by Ralph Naranjo

Airborne waste will affect any product, especially mast slide or car systems, Mercer explained. We always recommend that owners in these situations take the time to go up the rig and clean out the mainsail track or groove using a soapy solution and a rag. After that, you can lubricate the track or groove with a dry silicone lubricant. If you don’t clean it out properly and just start with lubrication, the lubricant will simply gunk up the area, and friction will be worse.

Tripp Fellabom of UK Sailmakers in Charleston, S.C., is a 38-year industry veteran. He told us that he, too, was a fan of the Tides Strong Track system, especially for someone like the owner of our hypothetical 27-foot Hunter.

For my market, the Tides Strong Track makes sense, he said. It’s inexpensive, easy to install, and really bulletproof. Theres just so little friction in the system. A further advantage, he explained, is that the system has no moving parts and essentially no fasteners. It is, by far, the easiest approach to a luff slide system. Its a no-hassle, relatively lightweight system.

Fellabom explained that most of his customers have boats in the 28- to 50-foot range. A lot of them come in to me wanting a fully battened mainsail. So, I tell them that they’ll need to be concerned about the slide system due to the increased loads those battens put on the track fitting. And most of them are aware of that and tell me, Yeah, I’m going to have to go with a system that has ball-bearing cars like Harkens or Ronstan’s. But, if the boats not over 50 feet, I always show them the Strong Track as an option.

For customers with larger boats (over 50 feet) who can afford more expensive options, Fellabom says that he prefers to steer them to Antal Marines system. “I love Harken products, but what Antal makes is very good,” said Fellabom. Like Harken, Antal offers two kinds of aluminum cars, one with sliders (the HS system) that are lined with composite fiber and one with captive ball bearings (the Fireball system).

“The HS sliders have a little more friction than you’ll typically sense on the Tides Strong Track, but they work well.” Fellabom explained.

We asked Fellabom why he recommends Antal’s system over others:

“I like Antal, because I’d rather rely on the composite-fiber bushings for boats over 50 feet LOA that are under heavy loading conditions. The ball bearings that are used in cars can wear out and then you have to take the cars off to replace them. That’s a lot easier now with captive bearing cars, and Harken does make slider cars without ball bearings, but those are generally for boats 40 feet and under.

Regarding other options, Fellabom said that he has had to replace a number of systems that used Rutgerson mast track cars.

“In my experience, anything with wheels that have contact with a mast has never worked correctly or wont have a long lifespan,” he said.

He added that his preference for Antal comes primarily from the fact that he has installed more of those systems than he has Harken’s Battcars. The only real downside to the Antal system, he said, was that it is more expensive than Harkens Battcars.

Master sailmaker Dolph Gabeler at North Sails in Costa Mesa, Calif., has been working with sailboat owners for over 40 years in locations around the globe. He told us that a 27-foot boat doesn’t really warrant a track or car system.

Honestly, few owners in that size range would be likely to spend $700 to $1,000 for a Tides Marine Strong Track system or a car-based system, Gabeler said. And no one in that size range would really need it.

“With a 27-foot boat,” Gabeler said, “you should be fine with just simple, flat slides. The Allslip slides, which are self-lubricating, are great choice, but those would only be necessary if the owner had a full-batten mainsail.” He said that simple white plastic slides like those from Holt Allen or Metalmast should suffice. “These are internal flat slides, and they’re the most economical option,” Gabeler added.

Another economical route, according to Gabeler, is to take a hybrid approach. “I would recommend one full batten at the top of the mainsail, and I would have that ride on an Allslip slide that was webbed to the batten fitting. Most owners in this ballpark are going to use a system similar to that.” Gabeler explained the main problem in small boats comes when an owner tries to add full battens that are attached to round slugs. That approach will not work, he said.

Gabeler also recommended that the owner of our hypothetical Hunter apply a dry lubricant to the track or groove on his mast. Wet lubrication collects dirt and salt over time, and thus adds friction. A dry Teflon lubricant would be the way to go. We usually suggest McLube dry spray, and (applying it) once a season should be enough.

Regarding the Bavaria owner, Gabeler said he would be a good candidate for the Tides Marine Strong Track system. He said that the system is a good option for boats from around 28 feet up to about 52 or 54 feet. In the case of a performance multihull, he pegged the upper limit at about 40 feet. Im a big advocate of the Strong Track system, he said. Although owners can install it, we often recommend that a local rigger be involved if were not managing the installation.

The big advantage of the Strong Track system, said Gabeler, is simplicity. As soon as you go to a car system, whether its Antal or Harken or Selden, you have to add a track with fasteners, and you often have to get a rigger involved. So its much more complex than the Tides Marine system, and its more expensive as well. Generally, those car-based systems cost $3,000 to $4,000 for a 50-foot boat, whereas the Tides Marine system would be less than $2,000. The Tides system isn’t just easier to install and maintain, it also has no moving parts.

In the case of larger boats that exceed his maximum length overall for the Strong Track, Gabeler said he recommends either Harken’s Battcar system or Antal’s HS system. My primary recommendation would be to stay away from any of the loose-ball systems. Captive ball bearings or the self-lubricating slides like Antal’s are the way to go. My preference is Harken, first, Antal second, and the rest of the existing products are third. Gabeler said that his preferences were based on his experience on the loft floor and on board hundreds of boats. He also favored Antal and Harken because of the worldwide support, making it easier to track down parts or get support should trouble arise, he said.

Tony Peelle, the loft manager at Haarstick Sails in Rochester, N.Y., concurred with the majority of recommendations fielded from the other sailmakers. “Your options begin with plain-old standard slugs or slides,” he said. “The next step up is the Allslip slide, which is larger and has shoulders, so it doesn’t bind in the track.”

Peelle had some interesting advice for owners of boats with external tracks. He said that although you can stick with traditional, nickel-plated bronze slides-which seem to last forever-you can switch to plastic slides for smoother operation. Like the others we consulted for this report, Peelle advocated the Tides Marine track for mid-size to larger cruisers, followed by the Antal and Harken track-and-slide systems. He pointed out that another plus for the Tides system is that you don’t need to send anyone up the mast.

Regarding maintenance, Peelle said, that it is important to ensure that the track or groove is clean and free of debris. He recommended thoroughly rinsing that part of the mast with fresh water.

Tim Stodola of Doyle Sails in St. Petersburg, Fla., told PS that his company doesn’t favor any particular equipment supplier. “We buy from all of these manufacturers,” he said. “And deciding what gear to use really boils down to what the customer is doing with his boat. Does he race or cruise? Does he sail by himself? Does he go offshore, stay in protected waters, etc.? And what is his budget for this, and then what is the specific application? All those considerations have to be understood at the outset.”

According to Stodola, the same systems that have been around for 10 years remain the industry standard, especially when it comes to gear for smaller boats. Stodola said his loft installs systems on a number of larger multihulls. These full-batten systems, because of the high loads, present particularly difficult challenges.

“Often times, a track system can really improve performance,” said Stodola. “We recommend the Tides Marine Strong Track system for some customers, but only up to a certain size boat-around 45 feet or so. It depends upon the size of the boat and the loading on the sail. If it were a catamaran, you’d probably move to Harken or Antal track system beginning at about 40 feet or so.”

Dan Elliott of Ullman Sails in Cleveland, Ohio, has been making sails since 1978. Prior to changing the mainsail luff track system, he would advise our hypothetical boat owners to examine their luff track and lubricate it. “After that, make sure that your slides are clean and not scuffed or nicked so that they move up and down the track and slide easily,” he said. “That’s the place to start.”

Elliott told us that he would absolutely recommend the Strong Track system for our hypothetical Hunter, particularly for someone on a budget. For this boat, he estimated the total investment to be less than $1,000. You can put this system on any kind of boat, and I can’t think of any reason that you wouldn’t use it on almost any boat 40 feet and under, said Elliot. The only drawback to this product, Elliott said, is the fact that the Strong Track coils can be stiff to unroll and install in cold weather.

For the Bavaria, Elliott explained that a boat like that was going to have a heavyweight mainsail with at least 9.3-ounce cloth, and as heavy as 11- or 12-ounce fabric, if it’s built to endure. Because of the size of the sail and the anticipated loads, Elliot said he would lean toward the Harken system for the Bavaria. I would go right to the Harken Battslide system, Elliot said. Its expensive, but its the best out there. Its absolutely frictionless; but for this boat, its probably going to be in the $6,500 or $7,000 range.

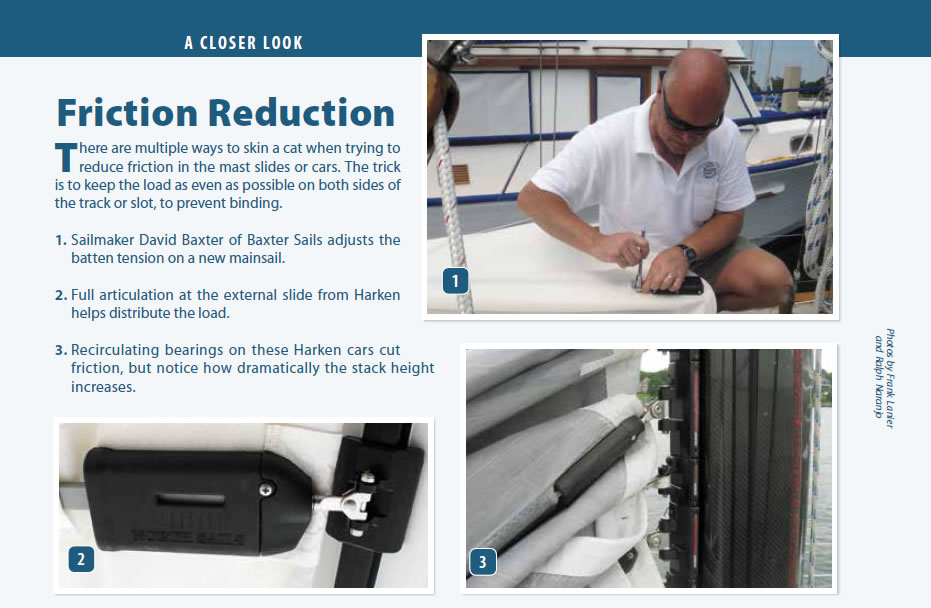

Elliott says he favors Harkens system because of the way the ball-bearing cars are engineered. The loads are equally distributed all around the bearings, and the bearings circulate so theres no point loading, and that means that the car cannot get cocked or pulled off angle. The luff will go up and down without problems.

He said that the Harken system is probably the only system he’d specify for a large cruising catamaran. He described how the large luff on the larger cats causes the battens to fan out so they are not perpendicular to the mast, putting an angular load on the car.

That’s when these Battslide cars are invaluable, Elliot said. Even though the battens aren’t perpendicular to the mast, the cars don’t bind.

Photo by Ralph Naranjo

Conclusion

Among the sailmakers we interviewed, there was a clear preference for systems that offer the least complexity, the most efficient performance, and the best endurance in the marine environment. These are criteria that PS has long prized for any form of onboard system. Both the Tides Marine Strong Track and the Allslip slide were nearly unanimous choices as first options by our interviewees. Smaller boats would clearly lean toward the Allslip.

What’s also clear is that systems with ball-bearing cars continue to suffer from a reputation for maintenance challenges despite the fact that almost every company offering these systems has successfully addressed those issues with captive ball-bearing cars.

We found it surprising is that few of our respondents mentioned mainsail track systems made by Selden, Karver, or Rutgerson, despite the fact that those products are readily available in the U.S. market. We also heard little about the Battslide system from Schaefer Marine, although its batten receptacles, if not the slides themselves, are popular among sailmakers. In addition, there are lesser-known products available that might prove to be reasonable options, including Facnor’s Facslide-plus cars and the Italian-built LuffShuttle.

Though the scope of this survey didn’t include connection devices, including batten receptacles where the slide or car connect to the luff of the mainsail, the majority of the sailmakers we interviewed were explicit that these are critical components in mast track systems. PS hasn’t conducted a comprehensive assessment of that hardware subset, but our initial responses indicate a strong preference for rugged batten receptacles that allow you to adjust batten tension at the luff of the sail. We will be taking a closer look at these components in a future article.

I read your article with interest, particularly the many complimentary comments relating to the Tides Strong Track system, so thought it worthwhile as an Australian sailor to relate my own experience with a similar system, Dutchman, with regard to the UHMPE track. Dutchman claim the track suffers little solar deterioration and after 10 years in tropical sun will retain 80 percent of its strength. All gear otherwise has a 5year warranty.

In year 6 for me, my headboard slides broke through the track, fortunately clean-through, so the sail came down without being jammed. Of course that meant the end of the system, now out of warranty, but the point I make is that solar radiation is much more damaging to the track than those using the system in less harsh sun environments presume, or that the makers and sellers recognise.

Today the remains of the track is lying on my verandah, out of the sun, but if I pick up a piece and bend it laterally, it just snaps. Of course Dutchman weren’t very interested in my experience, and presumably were happy I live in Oz.

What the hells wrong with you you dont use punctuation even for quotations are you an ignorant twit or simply an irritating one stop it before someone smacks you or worse

Hi Paul, I’ve fixed this now. The new website lost apostrophes during migration and we’re working on repairing the errors. I appreciate you reporting this. You can send any other problem articles to [email protected]. The original articles will be correct, and will often have the captions, tables and sidebars presented in a way that is easier to follow. You can find the original article in the publication month AFTER the date of publication — in this case it is January 2015. https://www.practical-sailor.com/wp-content/uploads/2014/12/1501_PS_Jan2015.pdf