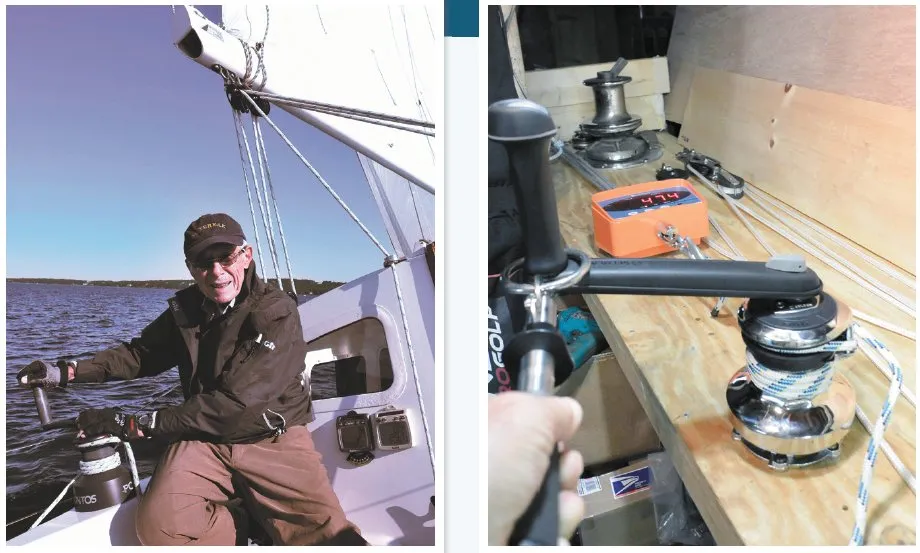

When comparing winches, its important to understand how input and output interface. The winch handle is a rotary lever that is the first stage of power amplification. The ratio of drum radius-to-handle length is the first force multiplier. An 8-inch handle and a 2-inch radius drum, therefore, deliver a 4-to-1 boost in pulling power and a 4-to-1 decrease in line-hauling speed.

When you switch to a 10-inch handle, the ratios are 5-to-1, giving you a 20-percent increase in power. Add a double grip to the longer handle, and a crewmember who normally would revert to counter-rotation (low gear) when the torque was around 25 pounds, now delivers 40 pounds of input into the winch at both the high- and low-gear ratios. In short, the simplest and most cost-effective power upgrade is a longer, double-grip handle.

Once you have the right handle, you should look at gear ratio, and then to power ratio. A gear ratio of 1:1 means one turn of the handle equals one turn of the drum. In this case, the only extra pulling power is derived from the lever effect of the winch handle. The purpose of gears in a winch is an equivalent to sprockets on the hill-climbing road bike; sprockets allow the rider to deliver more power to the back wheel, with less effort. A transmission does the same in a car.

Theres no free lunch here. However, rotary energy going in can be reapportioned via a gear train to increase pulling power, but this slows the recovery rate. The opposite is also possible. In a perfectly friction-less world, if you put 30 pounds of force into the winch handle (a 4:1 lever), on a winch with a 7:1 gear ratio in low gear, the output pulling power is 4 x 7 x 30 = 840 pounds. If you do the same on the Pontos four-speed Trimmer with an 18.6:1 low gear, the equation is 4 x 18.6 x 30 = 2,232 pounds.

On a new or well-maintained winch, friction losses account for 10-percent loss of efficiency when operating in the mid-range loads. The efficiency drops off a bit as the winch approaches its maximum load-handling capacity; bearings start to bind, and the spindle starts to tilt. If overloading occurs, however, it can permanently deform key parts inside the winch, and its efficiency decreases precipitously. This is why cruising sailors should not opt for smaller winches, even though they are not racing.