Global fuel supplies have been stretched as a result of the war between Russia and Ukraine, and to help alleviate this, the EPA issued a waiver permitting expanded sales of E15.

Beginning May 1, 2022, summer vapor pressure restrictions are lifted on E15, resulting in expanded sales in many markets. Although non-ethanol gas is available in some locations, it’s become very hard to find in many boating areas. We expect this situation to become more widespread, and we would not be shocked if the waiver E15 became permanent. Regardless, we expect to see E15 expand into more markets.

VAPOR PRESSURE

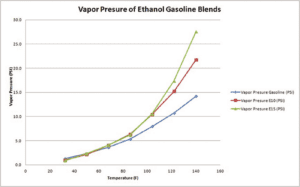

When you fill a portable tank cold and it warms up in the sun, the pressure of the vapor in the tank increases to approximately the difference in the pressure at the two temperatures. For example, if gasoline is dispensed at 55°F (it was in the ground) and warms to the local ambient summer temperature of 90°F, the pressure in the tanks will rise to about 2-3 psi. This isn’t too bad, just a little puff.

With E10 the pressure would increase to about 6 psi, something like a firm volley ball. This is a little scary, but still within the capabilities of a well-built plastic portable gas tank. (All tanks are leak tested to 10 PSI to meet EPA’s standards.)

The increased ethanol content of E15, however, means that pressure goes up even more rapidly with temperature than E10. A can left in the sun will easily exceed the 10 psi rating of a portable tank or jerry can. (Hot water from the home tap is enough to make E10 and E15 boil.)

During summer, if the tank is left in the sun, temperatures of 120°F can be expected, resulting in pressures greater than 20 PSI. At that point, we are well into the red zone, when tank fittings and fuel hose connections could begin to leak.

Plastic tanks will also weaken over time. Depending on the UV inhibitors used by the manufacturer, a plastic jerry jug exposed to Florida sunlight will lose about 6-8 percent of its tensile strength every year. Constant exposure will also result in degradation. An 8-year-old tank is only half strength or less. Bleaching, checking, and tiny cracks are signs that your tank might no longer meet safety standards.

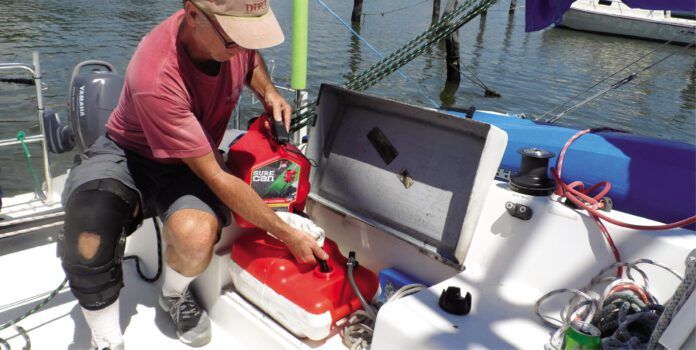

Bottom line: Keep fuel containers out of the sun as much as possible. Under a seat, covered, or painted white are all options. Regardless of appearance, consider replacing any fuel jug that is more than five years old and has been left exposed to constant sun for most of its life.

CORROSION

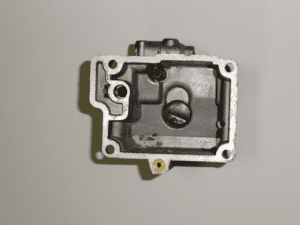

Ethanol is not that corrosive, but once it absorbs even a little water, it becomes an electrolyte and the aluminum and brass in the carburetor bowl invites rapid corrosion. Pits form in the bottom of the bowl, the puffy aluminum oxide gets stirred up, and next thing you know, the jets are plugged with a mineral deposit that no cleaner can remove.

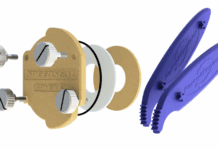

Bottom line: Keep water out of the tank or can by checking that the seals are in good shape, and closing portable tanks and integral tanks any time the motor is not actually running. Treat the gas with a good anti-corrosion additive, like Biobor EB or Stabile 360 Marine (see “Gasoline Additives in the E15 Era” PS December 2019).

ENLEANMENT

Ethanol blends require more oxygen to burn properly than gasoline, causing the engine to run lean. Lacking computers and sensors like cars, small outboards are tuned to run just a little richer than required, and the 5-8 percent or so increase in oxygen required is generally tolerated. However, even the slightest narrowing of the main jet can cause stumbling at full throttle.

Another common cause of high throttle stumble is a worn fuel connector on the outboard. All of the tilting up and down, and connecting and disconnecting wears them out. It starts with a tiny air leak. This leads to fuel starvation and enleanment. I’ve had these problems on every motor that I’ve owned for several years. This is easily diagnosed by pumping up the fuel primer bulb hard. It should quickly become uniformly firm, and stay that way as long as you pump.

Bottom line: Do not use E85 in outboards. If you do, damage is likely. Keep fuel jets clean by keeping water out. Keep a spare set of fuel line connectors on the boat, though it is usually the hose-end that goes first.

While we do not favor ethanol blends for boats, we’ve learned to live with E5 and E10, and so can you.