In our search for high-volume electric bilge pumps for an upcoming report, we came across a shaft-driven pump with such an impressive flow rate that we wanted to take a closer look.

Initially made for pumping operations on land, the Fast Flow pump has tremendous pumping capacity. The 2-inch-diameter pump can move 4,800 gallons per hour (gph) at 800 rpm, and up to 24,000 gph at 2,000 rpm. This compares to 1,000 gph for an average-size electric bilge pump. Our first thought was that the pump would make an excellent engine-driven, emergency pump. In fact, it has been used for this and other jobs on a range of recreational and commercial boats.

Photo (top left) courtesy of Yamaha Motors

Its important to note the difference between a bilge pump and an emergency pump. A bilge pump on a cruising boat is designed to rid the boat of normal accumulations of bilge water (rain, packing gland drips, etc.). Emergency pumps are designed to help keep your boat afloat in worst-case scenarios-the hull is breached in a collision, a grounding, or through-hull failure.

Emergency pumps require some significant horsepower, so most existing emergency pumps harness the boats auxiliary engine. Probably the most common engine-driven, emergency bilge pumps are the big bronze impeller-type pumps. Jabsco (www.jabsco.com) makes several belt-driven models. Its 2-inch-diameter pump moves 3,600 gph at 1,500 rpm. Adding one of these pumps requires an extra power take-off (PTO) for the drive belt.

The Fast Flow emergency bilge pump takes a different approach to harnessing the auxiliary engines power and adds some interesting features.

How It Works

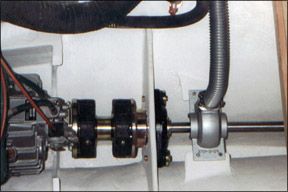

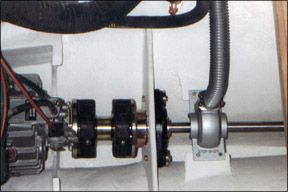

The Fast Flow pump comprises a permanently installed split impeller that mounts directly to the prop shaft and is enclosed within a split case. As long as the shaft is turning, the pump is operating and will start working automatically in the event of an emergency.

Constructed of cast aluminum, the Fast Flow pump has no seals, gaskets, gears, or filters. Designed to run dry continuously and in either direction, it requires no lubrication and will pump oil and small debris without being harmed. When not pumping water, it serves as a high-volume air blower, ventilating heat and fumes from the engine compartment.

Since it technically has no moving parts, the pump is both frictionless and essentially maintenance free, although the pump, discharge hose, and fittings should be inspected annually.

Installation

The Fast Flow pump comes in sizes to fit most any boat and, because of its split-case design, can be installed without removing the shaft. The smallest pump needs approximately 4 inches of clearance around the shaft, which can be an issue with some sailboats. Another issue is that the shaft (and therefore the propeller) has to be moving for the pump to work, meaning its not much help at the dock, and you better hope your emergency strikes in open water with no obstacles in sight.

Bottom line: The 2-inch-diameter kit lists for $600, which is about $300-$400 less than a belt-driven Jabsco emergency pump with similar output. The drive shaft installation, though robust and convenient, is less than ideal. The company is looking at other ways to drive the pump that would allow the engine to stay in neutral. This technology is certainly worth keeping an eye on.