The paint aisle is crowded with products to thin or clean up everything. Your dockmate suggests that X is the stronger solvent, that Y is safe to use, or that Z dries faster, but none of those rules is universal, and the best solvent is not a simple thing to declare. For example, if you want to dissolve salt, only water will do the trick. You see, it depends on what you are trying to dissolve.

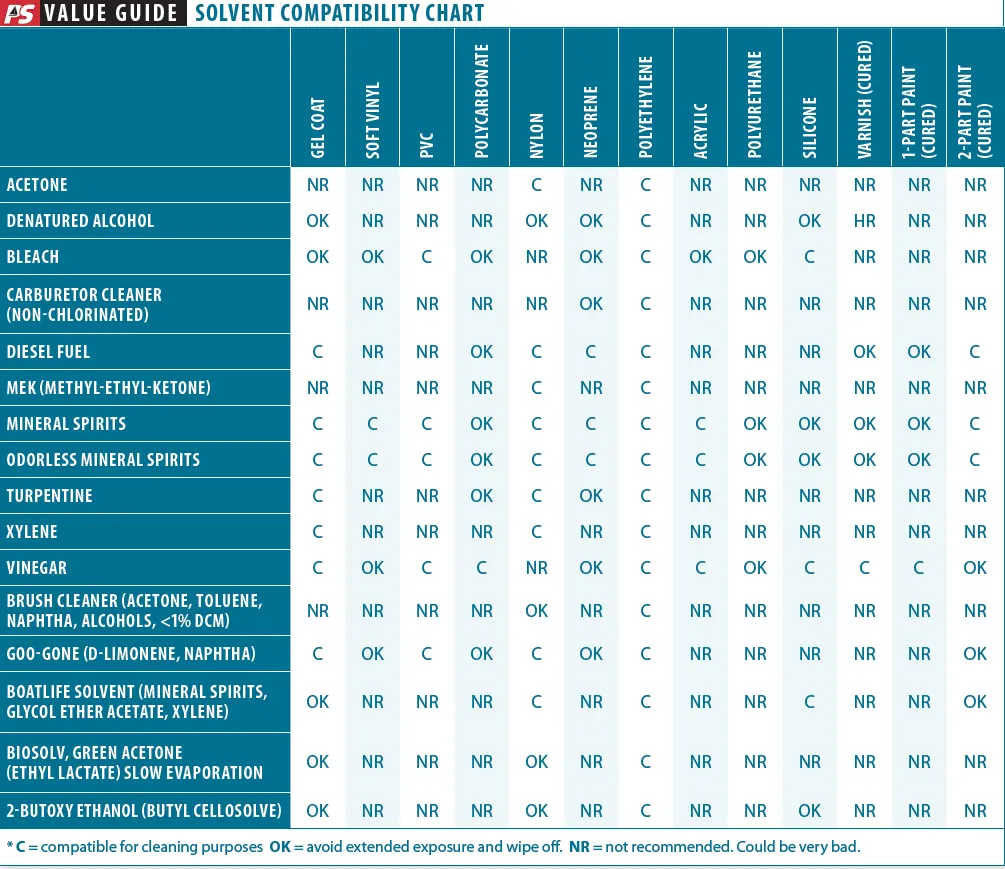

And then there is the matter of compatibility. One careless swipe of lacquer thinner, xylene, or MEK across your beautiful vinyl windows can ruin them forever, while mineral spirits is safe for taking off a little grease or adhesive. Drying rate matters; acetone is often recommended for removing self-adhesive residue and contact cement, but it dries too fast to penetrate a thick layer of adhesive and the vapor rapidly becomes explosive in a confined space.

General Considerations

Before we dig into recommendations and favorites, lets discuss the factors that guide our choices:

Compatibility. If the solvent will damage the underlying material, thats generally a non-starter for cleaning uses, the sole exception being surface preparation. The tricky bit is that compatibility often depends on how long, how high a concentration, and the exact formulation of the underlying surface or the solvent blend you are considering.

Like dissolves like. This is a little tricky unless you are a chemist at heart. Remember the water dissolving salt example? It works because water is highly polar, making it a good solvent for ionic substances like salt, most acids and bases, and even alcohols, sugars (like a poly-alcohol), aldehydes, and ketones (acetone). But it doesn’t do anything for oil or tar unless boosted with surfactants, heat, and agitation.

Drying Time. Sometimes the best solvent is not the fastest drying, but rather that one that lingers long enough to penetrate. Additionally, a solvent that evaporates like lightning-such as acetone-puts large amounts of vapor in the air, increasing flammability.

Toxicity. Working in the open with the wind at your back, toxicity may be a minor concern. Wear the appropriate respirator (Best Respirators for the Boat Yard, PS September 2017) and gloves, and you are safe. But move the job inside the cabin, particularly in cold weather when ventilation is reduced and a space heater is in use, and mechanical methods-scraper, heat gun, or maybe a wire wheel or eraser-may be both safer and more effective.

Blends

In some cases the resulting properties are the average of what you might expect from the substances applied separately; mix xylene and mineral spirits and the blend will dry a little slower and cut a little faster. On the other hand, some are synergistic. Consider soap and water; the soap acts as an emulsifying agent, allowing oil to appear to dissolve into the water. Other common cosolvents include acetone, MEK, denatured alcohol, and glycol ethers (not starting fluid, which is diethyl ether), or things like cellosolve and its relatives. Because they share properties with water (very polar) and petroleum (organic portions) they can bind the two together. Finally, reducing solvents (used to thin coatings) are carefully formulated to modify flow and while maintaining drying time and gloss; if the end result is important, perhaps it is best to pay the extra dollars. That said, you can always read the MSD and spec sheets; there is often a cheaper alternative for cleanup.

Generics

Name brands matter little here because the solvents should be the same, without measurable difference in quality. Most likely, several brands buy from the same chemical manufacturers.

Acetone. Acetone is very fast drying and useful for general surface prep, but in our opinion, is over-prescribed. We like the low health hazard rating, but it is very flammable and dries too fast to penetrate many materials, in addition to being the wrong solvent group (aldyhyde) for many adhesives and gums (most respond better to aromatic hydrocarbons).

Denatured Alcohol. As a solution in water with a few drops of dishwashing liquid, denatured alcohol is a great solar panel cleaner. It is a poor degreaser, but effective on some inks. Perhaps you have it on board as stove fuel, but it is no substitute for more effective petroleum solvents.

MEK (methyl ethyl ketone). MEK is handy when working with polyester resin and gelcoat, both as reducer and for clean-up. We use the recommended reducer for finish work, but MEK seems to work just as well.

Mineral Spirits. The workhorse for oil-based paint cleanup and degreasing, no kit should be without mineral spirits. Relatively slow evaporation makes it safe to work with (fire and health). It is safe for most surfaces, including clear vinyl, but test it in a hidden area and wipe off.

Diesel Fuel. You’ve got it, but gosh it stinks for a long time and doesn’t work as well as mineral spirits. Wed only use it in a bind. Same with gasoline; xylene is a better choice in that case.

Turpentine. Distilled from the sap of pine trees, turpentine has slightly greater solvency than mineral spirits, and thus is better able to revive old paint and remove paint that is nearly dry. If used to thin paint, less is needed. On the other hand, some people have an allergic reactions.

Xylene. This is one of our favorites, but it is somewhat toxic and the odor is unpleasant, so keep it outdoors or ventilate. It is safe on many (not all) surfaces, and yet it cuts a wide range of nearly dried paints and adhesives quite effectively. Compared to acetone, it is a better solvent for most coatings and adhesives. Because it dries a little slower, it lingers long enough to work through the layers, yet it will still dry in 5-10 minutes. Because it dries more slowly, it is less of a fire hazard, although still flammable.

Cellosolve. Not found in the average boatyard or hardware store, it is a common ingredient in many products, most notably Formula 409, to which it imparts a unique odor. We find it handy for softening and removing hardened paint that has gotten on gel coat. It softens the paint, like a solvent, allowing it to be wiped off, yet is easier to work with than strippers. Curiously, unlike xylene, it is not very effective as a degreaser (unless mixed into a cleaning formulation) or in removing paint that is still tacky. This is a special purpose product you probably don’t need. Keep it away from paint and varnish!

Vinegar. Vinegar is not generally regarded as a solvent, but it is. We mention it here because of its usefulness for cleaning up uncured epoxy, where it disrupts the polymerization process and makes the goop easy to wash away with soap and water. It is perfect for cleaning tools and hands after a job. We often wipe down large areas near where we have been working, just in case we missed a drip or smudge. Do NOT let it contact resin you want to cure.

VM&P naphtha. Similar to mineral spirits, VM&P naphtha is more volatile. It can be used to thin most oil-based paints and used for clean-up, but with increased odor and fire hazard.

Blends

Blends are a mixed blessing. On one hand, if you buy a reducer or brushing liquid from the paint manufacturer, you can be certain they have tested the blend and it will work. After all, they know what is in the paint. That isn’t to say you can’t successfully use a small amount of xylene or mineral spirits if that matches the composition, but for larger volumes of additive, we recommend caution.

Cleaning blends promise miracles, and sometimes a blend can be synergistic. On the other hand, can a brush cleaner be optimized for all paints, or a goo-remover optimized for all adhesives and residues? Not likely. Some are good values, but we tend to use generics.

Substitute solvents

We’ve found substitutes to be a mixed bag. Some are sensible reformulations that really do deliver with lower hazards. Others don’t make much sense to use. It matters what your substitute aims to replace. It might be fine for brushing thinner, but it could be a terrible reducer. In general, regard any substitute as a completely different product that might share some, but not all of the originals uses.

Kleanstrip Odorless Mineral Spirits Substitute. Sold through home improvement centers, this is about 70 percent emulsified water. If used to thin varnish it will ruin the job and the entire can. For thinning, we are very reluctant to use a replacement, not until we have a good idea of what is in it, so that we can gauge compatibility.

Low-Odor Mineral Spirits (Kleen Strip and other manufacturers). Odor is reduced by shifting the balance of distillates for aliphatic and aromatic to aliphatic only. Additionally, the distillation range (boiling point) is increased. The result is reduced odor, a reduced ability to cut grease, and no ability to clean up smeared polyurethane sealants. If used as a paint thinner, the drying time is increased. For most jobs we tackle, this solvent is effectively useless.

Biosolv Green Acetone. We’re still testing this one. First, its a cleaning solvent, not an acetone replacement for coatings. The primary active ingredient is ethyl lactate, which is a solvent with a wide range applications and low toxicity. It effectively removes self-adhesive residue, making it handy for use in the cabin. It can be used for surface prep, but it dries more slowly. Flammability is similar to mineral spirits. It can be washed off with water. Biosolv is an acetone replacement only in the broadest sense that it can be used for some of the same things.

Two Challenging Paint Strippers

Two chemicals have been on the EPAs radar for a while (Checking Chemical Safety, July 2017). The first has moderate toxicity, but has the nasty ability to penetrate most gloves and clothing in minutes, dragging other chemicals with it. The second is carcinogenic and neuro toxic and has been implicated in a number of deaths.

NMP. The EPA issued a proposed rule regarding NMP in January 2017, with two regulatory alternatives, but it has been held up by the rule-making moratorium. In March 2019 a request for additional comments was issued. The EPA is considering a range of restrictions, including an outright ban. Our advice is to avoid it. Read the MSDS. NMP, is often the main active ingredient in products labeled as lower toxicity or soy-based.

Methylene Chloride. The EPA banned the use of methylene chloride in consumer paint strippers in March 2019, although it is still on some shelves.

Conclusion

Read your MSDS and spec sheets. These disclose hazardous ingredients, basic properties, any physical hazard (flammability, burns), health hazards, and what precautions to take. Google solvent chemical computability and you can find tables of what solvents are compatible with which materials. And please feel free to drop us a line regarding any chemical, solvent, or cleaner you have questions about; we’ll get a sample and dig into it.

Latest project: Remove excess bottom paint from dingy: Paint is Pettit Inflatable Antifouling Paint 1841 applied onto Hypalon fabric AB brand aluminum hull RIB. I applied the paint above the water line. Whatever the dingy is floating next to, the black paint rubs off, leaving black marks on my or friends boats. Must avoid harming the Hypalon fabric and adhesive bonding the Hypalon panels together. Plan to apply topside water based light grey paint to cover area where bottom paint was removed. Appreciate any recommendation for how to remove excess bottom paint and selection of which topside paint to apply afterwards. Current plan is to wet sand paint off with 100 then 220 grit paper.

Cell: 858-354-1548

Can you add brake parts cleaner to the list of compatible materials? It’s an amazing solvent, but will destroy some plastics.

This is one of the most useful articles to keep handy. I think cleaning in general has a lot of misunderstanding yet I, at least, spend two or three hours a day cleaning and picking up after just myself. That might seem like a lot but take a second and think about it. Dishes, making the bed, washing clothes, floors, etc. It can add up quickly and I certainly don’t want to ruin something cause I chose the wrong cleaner yet I’d like to get it clean quickly. Thanks for putting this together and I look forward future installments.

What’s the difference between a “thinner” and a “reducer”?

Also, if :

“We use the recommended reducer for finish work, but MEK seems to work just as well.”, why don’t you use MEK? I assume it’s cheaper.