Practical Sailor LED Lightbulb Test

In this LED cabin light test, Practical Sailor looks at 17 light bulbs from seven manufacturers. The LEDs were tested to see which was the most worthy replacement for a 20-watt xenon bulb in a bulkhead-mounted reading light. Testers measure LED beam angles and intensity, LED power consumption, LED color temperature, LED radio frequency interference, and LED reading and cabin illumination. The LED lights tested include: Alpenglow TR LED complete brass fixture; three lights from Cruising Solutions; three lights from Doctor LED; four from Imtra; two from Opto Technology, two from Daniel R. Smith & Associates (DRSA) manufactured by Mast Products; two of Scad Technologies (Sailors Solutions) Sensibulbs; and one LED light from West Marine.

Mailport: 01/09

In the December 2007 Practical Sailor Advisor, you requested feedback on Ultimate Sole, a product for coating cabin soles. Two years ago, I added a -inch teak-holly veneer plywood covering to my sole and used Ultimate Sole as the finish. I first put on a sealer and then two coats of Ultimate Sole. It went on very easily and performed better than I expected. It is a hard, glossy finish that truly does offer nonskid properties. You look at the finish and think you will slide all over the place, but you don't! It is a wonderful product, and I wouldnt use anything else.

Finishes to Coat the Sole

As with all wood-finishing techniques, there are a million different "best" coatings for a cabin sole-the answer just depends on who you ask. Advice runs the gamut-from using the same urethane clear-coat recommended for basketball courts and bowling alleys to leaving it natural. According to Interlux (www.yachtpaint.com), its Cetol products can be used on cabin soles, but we do not recommend using them. Cetol Marine, Cetol Marine Light, and Cetol Marine Natural are relatively soft coatings and will not last long or wear well with the amount of traffic a cabin sole sees. The Cetol gloss overcoat is not as hard of a finish as most urethanes, so it would offer less protection but just as much slipperiness as a hard varnish.

Practical Sailor Names 13 Products Best Gear of the Year

Practical Sailor’s annual wrap-up of the year’s best sailing equipment looks at our favorite top-rated products from November 2007 to November 2008, including the Facnor furler for light-air sails, Scad Solo external holding-tank sensor, Pelican Recoil LED flashlight, and Adventure Medical’s first-aid kit for coastal cruisers. In the boat maintenance category, Interlux’s Micron 66 bottom paint and Spray Nine’s waterline stain remover garnered Editors’ Choice picks. Foulie sets (jacket and bibs) by Gill and Helly Hansen were tapped as Practical Sailor Editor’s Choice in apparel, and a host of marine electronics made the list, including the Icom CommandMic III remote mic and Garmin GPSMap 545s 5-inch chartplotter sounder. Jeppesen was recognized for its top-notch electronic chart updating services. Other top gear picks were the Acco proof coil mooring chain and the Achilles HB315-LX fixed-transom inflatable dinghy.

An Inflatable Bottom Job?

There are two schools of thought when it comes to applying antifouling to Hypalon. Were of the "don't do it" camp for a few reasons. First, once bottom paint is applied to Hypalon, it can be very difficult to remove without risking damage to the material. Second, if you ever store the dinghy on deck or deflate it for longer storage, you can be sure that paint is going to rub off on things youd rather it not foul-for instance, tacking headsails or the deck, if the dinghy is stored there. Even if you leave the dinghy in the water for long periods of time without use, cleaning the bottom regularly should be sufficient. The folks at Mercury agree with us on this point. Mercury Marine Sales Manager Larry Piechocki told Practical Sailor, "Once this paint is on the tubes, it will never come off. Im not a big fan of painting inflatables, but that is up to the customer."

Best Boating Knives

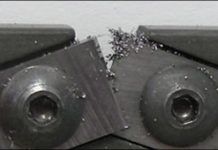

David Boye, the Arizona knifemaker whose unique folding boat knife of cast dendritic cobalt won our June 2000 sailors knives bench test and was a reference standard for our March 2004 revisit, recently introduced a new model Basic 3 Cobalt knife. These knives doggedly retain a cutting edge when going through tough, blade-resistant materials like rope, cardboard, or even old rugs. Others give up long before the job is done. In our experience, Boyes cobalt knives last much longer-and when they finally do slow down, they can be resharpened with just a few strokes on a medium stone. The difference, we reason, is in the metallurgy. Boyes cobalt blades are "cast to shape and retain the pristine crystal network of highly dendritic (branching) bonded carbide throughout the blade, which aids in cutting and maintaining the structure of the cutting edge," according to the maker. Most knives are from steel that originally contained a similar crystal microstructure, but then underwent rolling, stamping, or forging to shape. This process breaks down the original carbide microstructure of the metal. The carbides at the edge are then no longer rooted into the overall microstructure. Complex heat treatment is then applied to develop properties such as hardness and toughness.

Best Ethanol Fuel Treatment for Boat Engines

Since the introduction of ethanol fuels at dockside pumps, weve had a slew of reader inquires about the effects of E-10 on fuel lines, fuel tanks, two-stroke engines, and four-stroke engines. We recently tested some products designed to address these issues, specifically those that claim to combat the problems associated with phase separation in E-10. Practical Sailor tested: E-Zorb from Marine Development Research Corp. (MDR), Sta-bil Marine Formula Ethanol Treatment from Gold Eagle, PRI-G from Power Research Inc., Star Tron from Star brite, and Techron from Chevron. The claims of each product varied, but the test products fell into one of these general categories: conventional fuel storage additives, ethanol fuel storage additives, and restorative gas additives. Our tests looked at whether the additive itself would leave ash deposits, gum deposits, or residue that might cause contaminated lubrication oil; whether an additive had a tendency to emulsify, suspend, or absorb free water; and whether the additives could delay the onset of cooling-induced phase separation.

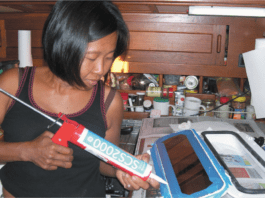

Teak Deck Caulks Rated for Durability and Resistance to Chemicals

Seven caulks were applied to teak-deck seams in June 2006. At that time Practical Sailor looked at ease of application, adhesion, durability, and resistance to chemicals. Updates in the September 2006 and March 2007 issues looked at pliability, durability, and adhesion. This update tests caulks for long-term durability and resistance to chemicals. A 4-inch bead of each teak caulk that was applied two years ago to 16 different panels was doused regularly with chemicals that teak decks are likely to be exposed to (motor oil, acetone, nleach, etc.). The test group is a mix of polysulfide, polyether, silyl modified polymer (SMP), and silicone-based products. Seven products were tested: Boatlife Life Caulk; BoatLIFE Teak Deck Sealant; BoatLIFE Type P; Bostik/Simson MSR; Teakdecking Systems; MARITIME Teak Deck Caulk, and West Marine Multi-Caulk.

Checking In With the Test-Boat Fleet

In addition to our annual paint-panel tests, Practical Sailor has a host of ongoing head-to-head field tests of the top-performing antifouling paints. Our test-boat fleet allows us to evaluate paints in real-world conditions on boats that run the gamut in terms of usage, storage, and cruising grounds. For the head-to-head tests, each boat’s hull below the waterline is divided into four equal sections (two per side). One paint is applied to the port bow and starboard aft section, while another is painted onto the starboard bow and port after section, giving both paints equal exposure. Paints are applied following maker’s instructions, and an extra coat is applied at the waterline.

Last Call for Top-Rated Bottom Paints After Two Years

Our two-year test wraps up with 20 top-rated paints. Unlike the last two-year results when hard paints dominated, the group is split with 10 self-polishing or ablative paints and 10 hard paints. Our Recommended, Best Choice, and Budget Buy picks also are divided pretty evenly. In past rating cycles for this panel set (October 2007 and March 2008), Interlux Micron 66 and Sea Hawk Biocop TF were named top picks. These two still lead the pack at the two-year mark. Both are expensive, with Micron 66 costing $220 per gallon and Biocop TF ringing in at $228 per gallon. They also both use zinc pyrithione as an anti-slime agent. Our top bright-color paint after two years in the water is Blue Water Kolor-another expensive paint, priced at $170 per gallon. The top-performing two-year paint suitable for race boats is Interluxs VC Offshore. Pettit Trinidad SR, well polished, would also be a good choice for racing.