Mailport: September 2013

In response to Whats in the Practical Sailor Toolbag? (PS, January 2012): How about a list of tools that a live-aboard cruiser should carry? Given storage, power, and workspace limitations, many of the suggested tools are not feasible and may require alternatives. For instance, I carry a major Dremel toolkit, and it cuts the very occasional holes I need for switch installation, etc., plus helps me with sanding and minor refinishing work. I use my Dewalt 18-volt right-angle drill probably twice a month for repairs and upgrades. I also use my cordless screwdriver several times per year, especially when removing and reinstalling my headliner while chasing wires. Most others are tools that don't require electricity, but there are many.

Mailport: July 2013

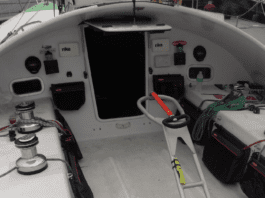

A few issues ago, you had a short article on deck hardware (blocks, traveler, cars, etc.) that included Garhauer, and you mentioned that the manufacturer offered individual parts and complete systems that allow conversion from on deck to cockpit adjustment of the car position. We recently installed the EZ adjustable genoa car system from Garhauer and are very pleased with the results. This equipment fits on existing traveler tracks, is easy to install, and performs as advertised.

Summer Sailing Gear

Summers warm breezes and lazy weekends have arrived, so PS testers have put together a lineup of cool toys and tools for the dog days. Tower Adventurer Inflatable Standup Paddleboard: Inflatable SUPs are sprouting up everywhere on the Internet; many boards are identical, made by different brands at the same factories in China. Quality varies. Generally, boards 6 inches or thicker offer better stiffness and stability, making them easier to ride.

After-market Cordage Treatments

Practical Sailor treated used running rigging with Downey fabric softener, Granger’s 2-in-1 Cleaner and Waterproofer, and Nikwax Rope Proof to determine whether softeners or waterproofing treatments improve the performance of nylon and polyester double-braid lines on a boat. Can aftermarket treatments improve line handleability, reduce water-weight gain and strength loss, and prevent lines from freezing in colder climates—without damaging the lines? We also wondered whether any treatment would keep aging lines from squeaking as they run over blocks under high strain. Our tests found the definitive answer.

Field Testing Treatments

Practical Sailor followed manufacturer instructions for treating used lines, with one exception. Both the Granger’s and Rope Proof advise users to dry the treated ropes in a warm dryer after soaking them in the diluted solution and laundering them. As we’ve learned in past tests (PS, July 2011), most rope manufacturers caution against placing rope in a heated dryer, and cleaning them in a washing machine can be damaging (to the rope and the machine). So for this test, we opted to clean the test ropes by gently agitating them in a bucket by hand, rinsing them in a pillowcase on a shortened gentle cycle, and air drying them. (We did test one set of lines by air-drying and heat-setting, but there was no measurable difference.)

Practical Sailor’s 2011 Gear of the Year Picks

Each year, as the fall boat shows—and the deals that come with them—appear on the horizon, we pore over the numerous products we’ve reviewed in the previous 12 months to select the cream of the crop for our Editor’s Choice awards. We hope the list will help readers better navigate any boat-show or end-of-season shopping. This year, we picked from the Best Choice products evaluated in the September 2010 through August 2011 issues. The 2011 GOTY roster includes an electric outboard, some stout bullet blocks, electric marine toilets, bilge pumps, chafe gear, and marine maintenance products like bottom paint.

Buyers Guide: Choosing a New Cruising Main

As with any big ticket item, choosing a new mainsail involves a number of choices, each of which are driven by an equally diverse list of factors to consider, from the type of boat (cruising, racing sailboat), and area sailed (inshore waters, coastal waters, or bluewater), to the type of sailor you are (performance-oriented hard charger or weekend warrior). Practical Sailor offers a step-by-step rundown of the available options and the selection process our testers experienced when we shopped for a new mainsail for our Chesapeake Bay test boat. While the decisions will vary, the exercise can serve as a template for any sailor looking to upgrade a mainsail.

The Multifarious Mainsheet

The mainsail is a big part of the motive power of almost every sailboat. The art of mainsail control, however, is a relatively modern one. One tool that greatly facilitates mainsail control is the traveler. Traditionally, the mainsheet traveler was a heavy bronze or iron rod that allowed some control over the position of the boom relative to the centerline of the boat. In heavy air, the main could be eased down to leeward without easing the sheet, helping to keep the boat on her feet with the main still sheeted down. Compared to modern travelers this is a primitive system, but it can be made to work.

Clear the Decks: Anchor Wells and Bow Rollers

Ever since some ancient mariner broke a toe tripping over the killick stowed in the bow of his curragh, sailors have sought to solve the mysteries of ground tackle stowage. The solutions have been endless, and as a rule compromises. A significant portion of the interior volume of a 19th century warship was given over to the storage of anchor rode. Even aboard modern boats, the search for the proper stowage of several anchors and chain, plus hundreds of feet of sometimes slimy nylon anchor line, is one that occupies both designers and boat owners. Two "modern inventions" — the anchor well, and the bow roller — have greatly eased many of the problems of ground tackle stowage. But even these developments vary greatly in quality and design, some creating more problems than they solve.

Smooth Runnings: Bullet Blocks Battle

Practical Sailor tested more than a dozen bullet blocks (sized 40 to 45 millimeters) from eight marinedeck hardware manufacturers: Barton, Garhauer, Harken, Karver, Holt, Ronstan, Schaefer, and Selden Mast. The units tested were ball-bearing and roller-bearing designs, and the growing trend toward more composite material and less metal construction was evident among the products. Blocks were loaded to 200 pounds-well within the safe working load for the test blocks-and testers measured the amount of force required to move a line in a closed loop set up. Once the efficiency test was complete, the blocks were subjected to an aerated saline bath to gauge corrosion and oxidation tendencies. Weight, price, safe working load, cheek material, and attachments were also evaluated.