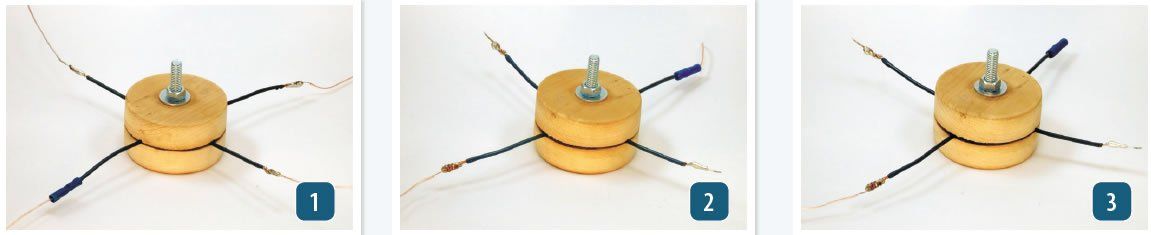

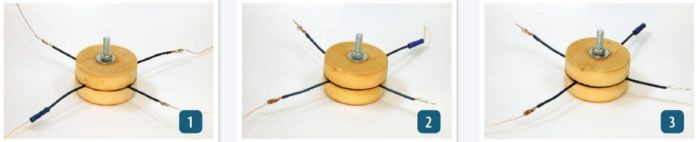

Our test focused primarily on the small-wire connections tensile strength, with and without solder, but we also looked at their durability under tough environmental conditions. We tested the pull-out strength without solder and the pull-out strength of soldered connections at 400 degrees by heating the connections in an oven to simulate overheating conditions. We tested fatigue by spinning a 6-inch length of splice wire at 650 RPM in a simple device that we called the wire-fatigue whirligig. Finally, testers soaked all samples for four months in salt water to accelerate corrosion, and then, we repeated the fatigue test.

Ordinarily, it would be good practice to cover all wire splices with heat-shrink tubing. Soldered splices definitely require heat shrink for insulation. However, for corrosion testing, we left them bare. We wanted to judge the connection, not whether the shrink seal failed. Heat-shrink tubing-adhesive lined for damp locations-is always good practice.

Testers also left the wire nuts bare; on land, where wire nuts are permitted, taping them is required when vibration is expected (motors, industrial settings), and some suggest filling the nuts with sealant on a boat. We doubt either method is fully dependable in a marine environment. We did use heat shrink in some of the fatigue tests, and in those cases, we used plain heat-shrink tubing.

Great research and write up. I always thought dielectric grease was good to use around a wrap before crimping, thereby filling all spaces to prevent corrosion. Can you comment about the use of dielectric grease?

Ron W.

Everett WA

Sorry, wrong article, ignore.