David Shih has quite a story to tell. The boat of his dreams brought on a nightmare of repair work—and YouTube fame. Shih isn’t alone, at least in the nightmare part. Shih’s story is one of many about bulkhead problems on the Lagoon 450 catamaran that have gotten widespread attention online. The attention persuaded Lagoon, a brand owned by Beneteau, a French public limited corporation (SA) that is one of the world’s most famous boatbuilders, to take action.

At first Shih noticed the interior joinery had shifted. Then the rigging got loose. Eventually he worked up the courage to look in the corners of the engine room, behind lockers, and even removed some trim. Cracks were everywhere—in bulkheads, in stringers, and in floors.

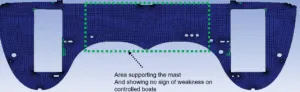

The most obvious failure was in the main bulkhead, the massive lateral bulkhead located near the mast that ties both hulls and the main cabin together. Shaped like a flattened upside-down U, this is one of the most important structural elements in a catamaran, preventing the hulls from bowing outward under rigging loads, or twisting excessively in a cross sea.

Shih was nearly certain that the trouble he found wasn’t caused by some prior damage. He noticed parts of the main bulkhead that were only partially bonded to the hull structures. He found bulkheads and stringers that were simply glued rather than taped and glassed into place. It was the sort of construction that one sees in a travel trailer, but doesn’t belong in offshore boat construction. His suspicions were confirmed when he got in contact with other owners whose boats had no history of collision or grounding, or conditions that a sailor would regard as extreme. They, too, discovered warped and fractured main bulkheads.

According to Shih, at first, there was hesitancy among the owners to talk openly about the problems. Reveal flaws in your boat and resale value can plummet. In the case of a large catamaran, a serious flaw could mean tens of thousands of dollars in lost value.

Not surprisingly, even owners of other Lagoon models that showed no signs of weakness or damage, objected to open discussion of the bulkheads in the 450 model. They feared their boats would be devalued by association. So the problem, which first came to light in 2020, did not immediately get widespread attention.

When dozens of owners voiced their concerns on YouTube, Facebook, or other social media outlets, Lagoon’s Brand Director Thomas Gailly took heed, and the company put together a Lagoon 450 Support page (www.cata-lagoon.com/en/lagoon-450-support) addressing their concerns. They also prepared a repair kit to stiffen the main bulkhead, and published guidance on how to install the repair kit. It was a major repair that required removing a great deal of interior trim.

REASONABLE EXPECTATIONS

When buying a new fiberglass boat, it is reasonable for an owner to assume the basic structural integrity—hull, deck, and bulkheads—will remain intact for about 30 years, assuming we don’t expose it to extreme conditions that will overstress the boat (a hard grounding, for example). Lagoon’s response to the bulkhead debacle suggests that abuse as defined in the owners manual may be a cause for some of the failures.

The following are some of Lagoon’s examples of “abnormal” use of the boat, which according to Lagoon, could overstress the hull and eventually lead to the sort of damage that owners have been reporting in the Lagoon 450.

• Sailing with more sail area than allowed on the Owner’s Manual sailing advice.

• Powering against sea and wind for a long time at 30-degrees off the true wind.

• Sailing in very shallow waters to a point where waves could end up in occasional groundings.

• Anchoring in very shallow waters to a point where waves could end up in occasional groundings.

• Grounding.

• Tightening the rig out of the mast manufacturer specification.

• Improper haul out and storage.

Yes, catamarans flex more than monohulls. Beating into seas generates powerful torque on the hull. But cheap plywood with a low thickness to cord ratio and no edge flange is not the way to build the main bulkhead on a 45-foot catamaran, in our view.

In most of the cases we reviewed it seems very unlikely that the failures were due to extraordinary circumstances—a bone jarring grounding, hurricane damage, or being dropped from a Travelift, etc. By all appearance, it seems the normal stress and strain that a boat encounters at sea was simply too much for some of these boats. It is worth noting that this is the sort of stress and strain that Lagoon’s other models seem to shrug off without significant damage.

THE SCOPE OF THE PROBLEM

Because of a natural tendency among owners to handle things quietly, no one is quite sure how widespread the problem is. According to Lagoon’s website, about 1,100 hulls were built from 2010 to early 2020 when the line was discontinued. As of August 2021, Lagoon said it had been contacted by 155 owners, and that 50 boats with bulkhead-related problems were being repaired or had been already repaired. Although we requested them, updated numbers were not provided to PS at the time of this publication.

The repaired boats all showed the same bulkhead vulnerabilities, and whether the weakness became apparent often depended on age, construction details, and how the boat was sailed. No sunk or abandoned boats have been blamed on these failures. Lagoon reinforced the passageway beam in models built after 2012, but admitted no flaws, describing the change as a typical in a boat model’s production cycle.

POSSIBLE CAUSES

It appears several causes are at work. Ruling out extreme events, the failures we observed are likely related to under-engineering, material selection, or quality control at the factory.

Poor bonding. Many of the bulkheads pulled away from the hull or adjacent structure without signs of wood failure. It appears the glue did not bond properly. This suggests a lack of surface preparation before bonding.

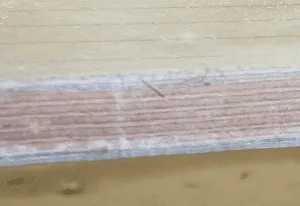

Weak material. Several cases of buckling bulkheads that we’ve reviewed suggest the use of materials that were not capable of withstanding prolonged ocean sailing loads. In short, the bulkhead plywood laminate was too weak.

Anticipating the loads on a main bulkhead of a cruising catamaran is not rocket science. The loads can be simulated by computer and the required strength to withstand such loads has been published in engineering manuals for more than 100 years.

Based on what we’ve been able to discern from photos taken by owners, the plywood used in the bulkheads of the Lagoon 450 appears to be a more economical variety, not the high-quality, high-density, high-strength marine grade plywood that would be preferable in a structural bulkhead.

As for Lagoon’s repair plan, sandwiching the weakened bulkhead section with new plywood as a repair— initially suggested by Lagoon—strikes us as a band-aid solution that does not solve the underlying problem. Without further FEA analysis, any underlying engineering problems are speculative.

LAGOON’S RESPONSE

Eventually, Lagoon mounted a strong response. They offered to inspect the forward bulkhead (only one of the common failure locations) at no cost if the boat was brought to an authorized dealer or service center. If cracked, the bulkhead would be repaired by sandwiching the fractured section in what amounts to a mechanical splint. Additional plywood would stiffen and straighten the bowed or broken structure.

If the boat is still covered by the three-year warranty, the full cost of the repair will be covered. If the boat is out of warranty, only the labor will be covered by the repair. The repair is guaranteed for one year. Lagoon says it is responding to every owner, even those whose boat’s do not show signs of bulkhead damage.

Lagoon had the original designer perform finite element analysis on the main beam design only. According to Lagoon, this analysis found that this structure had an adequate safety factor to withstand predicted loads. The analysis assumes there are no factory flaws. Notably, it did not predict the failures experienced by owners, nor did it describe the impact of a bulkhead failure on surrounding structures.

Other bulkheads and structures were not included in this finite element analysis, and a hull bulkhead does not function in isolation. If parts of the design were either under-engineered or poorly executed, a subsequent FEA would help identify these weak points.

Lagoon owners said they were told that because the boat must flex, some “settling” will occur. It is true that flexing can be expected, but based on what we’ve observed in the damaged boats, Lagoon’s bulkhead is a brittle design that is bound to crack. A flexible structure is not a weak structure, but one that can absorb loads without cracking.

Lagoon contends that the design itself is not flawed. Among other things, they point to their long history in the demanding charter industry as evidence of their robust specifications.

How concerned should 450 owners and prospective buyers be? Designed for charter use, these boats have more miles under them than any other cruising cat of similar size. But if you are buying one, have the surveyor crawl in and inspect every corner. Remove the covers and inspect the forward bulkheads. If they have been repaired, that’s probably good. Owners who see any sign of over-stress or suspect a weakness at the bulkhead should contact Lagoon.

CONCLUSION

Lagoon’s long history in the charter trade is proof that the company knows how to build boats that can handle abuse. And the company appears to be making an earnest effort to keep owners happy.

The Lagoon 450 has a lot going for it in terms of easy handling and comfort. However, sound engineering and quality control during construction should always take priority over cosmetics. This becomes especially important as the market demands faster, lighter boats (see “Multihull Madness,” March 2017).

Favoring quality construction over creature comforts is never a mistake, and sometimes that means buying a smaller boat, or an older, well-maintained one built to a higher standard.

2. A partial bulkhead is hand-laminated on the floor at a South African builder. Loads can concentrate at corners in the bulkhead.

3. An interior view of a catamaran under construction shows where the bulkhead has been bonded in place with some tabbing.

4. Both plywood and end-grain balsa core stiffen this main bulkhead which shows a desirable, low-resin matrix in the fiberglass laminate.