Photos by Ralph Naranjo

383

In some ways, the good ole days just weren’t that good. Just ask any old salt who’s watched an expensive canvas boat cover or awning mildew, rot, and fall to pieces. When Sunbrella hit the waterfront nearly four decades ago, the organic deterioration of covers, dodgers, and awnings was put on a short leash. Yes, the ravages of Mother Nature—from sunlight to acid rain—continued and sea gull droppings still took their toll, but compared to the carnage that occurred with organic fiber canvas, the strides forward were significant.

Today, there’s a lengthy list of cover material options ranging from not-so-good-ole, biodegradable cotton canvas—with a one-year warranty—to acrylic, polyester, and vinyl products, as well as blended fabrics. Some come with a five- or even 10-year warranty and are made of synthetic, solution-dyed yarns that have given the new “canvas” a good name.

The solution dying process means that the yarns are extruded with color already in place. This is a better bet when it comes to sustainable retention of vibrant hues and keeping the color from ending up on the deck. Many of the acrylic and polyester materials are breathable, a feature that somewhat lessens the greenhouse effect under dodgers and cockpit enclosures, and also lessens dreaded mold and mildew growth.

287

When it comes to fabricating a long-term, waterproof fabric cover, it’s hard to beat the combination of vinyl and acrylic or vinyl and polyester. Products like Sea Mark (www.haartz.com) and Stamoid (www.stamoidmarine.com) fit the bill, but they also invite mildew by retaining condensation dampness. (Former PS Editor Nick Nicholson reported on his experience with Stamoid in the Dec. 1, 1999 Offshore Log.) The first dodger ever custom-made for PS Technical Editor Ralph Naranjo’s Ericson 41, Wind Shadow, had a vinyl layer sandwiched between polyester. This made for superb leak protection, but in the tropics, the organic growth on the underside of the polyester was so intense that it necessitated monthly cleaning with diluted bleach, and by the time the Indian Ocean was splashing over the deck, the dodger had failed from the inside out. After that, Wind Shadow was always dressed in Sunbrella acrylic awnings, dodgers, and covers, and in this round of testing, we’ll see how the time-tested favorite stacked up against relative newcomer WeatherMax in our long-term test.

352

What We Tested

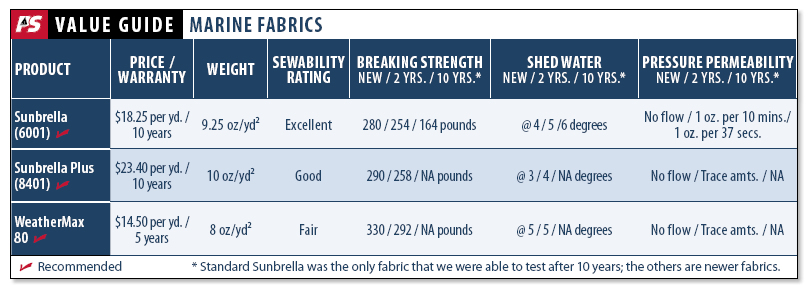

Sunbrella is a flagship marine fabric made by Glen Raven Mills in North Carolina. We tested two types of Sunbrella material: the standard 9.25 ounce (per square foot) cover/awning material and the urethane-coated 10.25 ounce Sunbrella Plus with improved water resistance.

The difference between the standard Sunbrella and Sunbrella Plus is a polyurethane coating on the underside of the material. It ramps up water-repelling ability and reduces the need to re-treat the surface with a water-repellent solution. Standard Sunbrella is made of the same acrylic fabric sans the urethane coating. It’s identical on both sides, and its sewability is one of its top traits.

WeatherMax is made from Safety Components’ trademarked filament yarn SaturaMax. It is a UV-stable polyester with a textured woven surface; it is breathable and repels water. The Ottoman weave is attained by combining a plain and basket warp and weft weaving process.

Two popular sail-cover makers, North Sails (www.northsails.com) and Lee Sail Covers (www.leesailcovers.com), use WeatherMax as their preferred material, even though the lion’s share of the industry still uses Sunbrella as the fabric of choice. There are an additional dozen or so other coated, multi-layered or breathable fabric alternatives, many of which are better suited to powerboat needs.

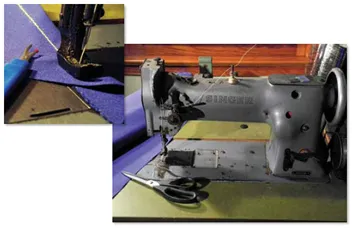

Wondering why so many canvas shops have settled on Sunbrella, we chatted with a half-dozen pros. Here’s a summary of their feedback: Handleability is a big consideration, and many find Sunbrella more user-friendly. The material’s texture is sewing-machine friendly, and with an industrial walking foot or a conventional-feed machine, there’s no seam puckering or slippage. Add to this the good blend of durability, color retention, and aesthetic appeal, and Sunbrella seems to hold sway among loft pros as well as consumers. There’s been growth in interest in Sunbrella Plus for those seeking long-term water-shedding ability. Those who have grown comfortable with the greater challenge of sewing up WeatherMax seams are pleased with its ruggedness and durability.

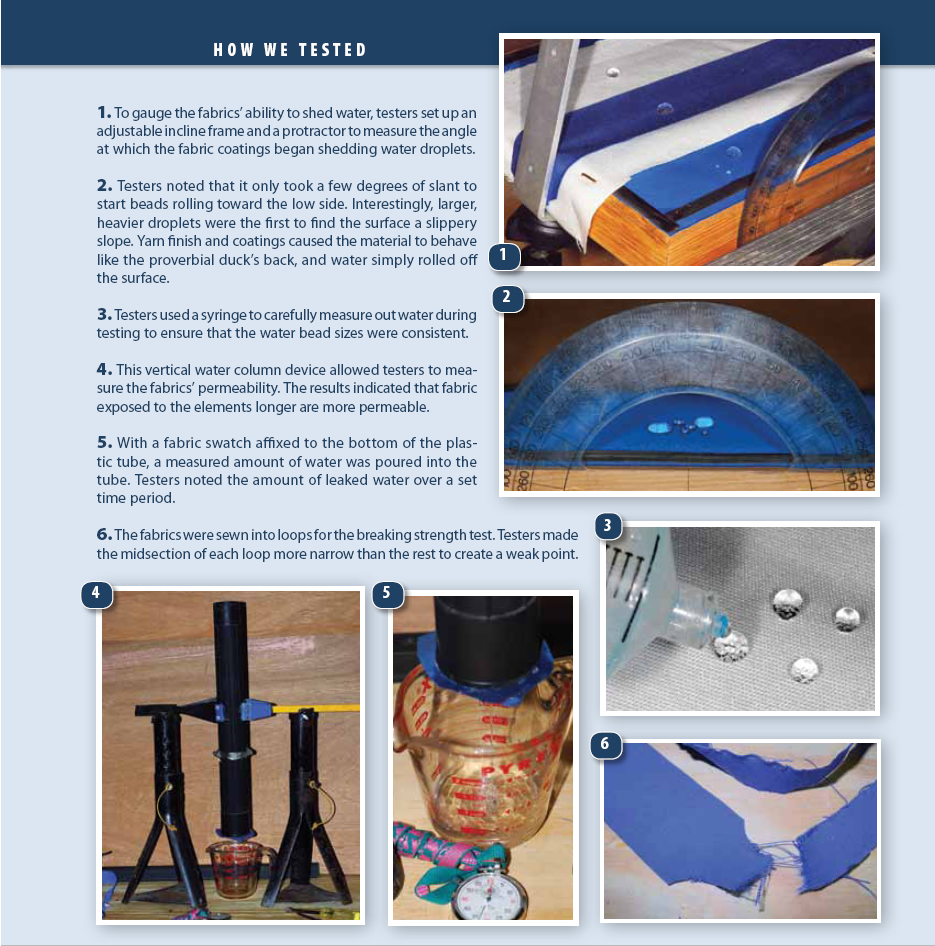

Practical Sailor divvied up this evaluation into on-the-water and bench tests. For test protocol specifics, check out “How We Tested.”

252

What We Found

Looking at a nicely fit dodger built from either Sunbrella or WeatherMax will leave many consumers with a hard-to-make decision. Pick up a piece of either material, and there’s a much more noticeable tactile difference. The clothlike Sunbrella has a familiar, canvas-like feel. WeatherMax, on the other hand, seems less like fabric and more like a membrane of sorts. And although it’s uncoated, it has a finish that’s slick, a little rubbery, and not nearly as clothlike as Sunbrella.

Both the standard Sunbrella and Sunbrella Plus are made from 100-percent acrylic fibers, and our tension testing revealed that both are quite durable, maintaining their strength despite UV and chemical degradation. However, testers noted that both also were prone to flogging chafe and should be kept clear of hard surfaces whenever possible. Sunbrella offers a 10-year limited warranty.

The non-coated WeatherMax material has a Hydromax finish, which testers noted was still water resistant after two years of full-time exposure. The polyester fabric at the core of WeatherMax was 30 percent stronger in tension than Sunbrella and was less prone to low-load elongation. It handled the flogging and chafe delivered by our “wind tunnel” testing better than the Sunbrella fabrics, but neither survived prolonged fluttering stints at 65 miles per hour. WeatherMax fabrics have a five-year limited warranty.

Strengthwise, the 8-ounce WeatherMax nosed out the slightly heavier Sunbrella, a fabric that weighed in at 9.25 ounce per square yard. (Sunbrella Plus weighed in at 10.25 ounces per square yard.) But this isn’t all that significant because unlike cordage, dodgers and Biminis aren’t in as tenuous of a tug of war.

As far as the water-repelling game goes, the coated, breathable Sunbrella Plus held the edge, and at the two-year point, the WeatherMax was a bit more water repellent than standard Sunbrella—but again, the difference has minimal significance as a few drips in the cockpit usually go unnoticed. (And covers that have lost some of their repelling ability can be rejuvenated with 303 High Tech Fabric Guard or other similar treatment. For more on faux-canvas care, see “Tips & Techniques.”)

Conclusion

In the final analysis, we found that both Sunbrella and WeatherMax were big winners in our faux-canvas sea trial. Cover-shop pros seem to be able to craft exacting sewn seams with WeatherMax while most do-it-yourself sewers will rightly gravitate toward Sunbrella’s excellent sewability characteristics. The mechanical properties do slightly favor WeatherMax, but unless the material will likely be flogging against a hard object, either will suffice as a dodger or Bimini.

When it comes to awning material, WeatherMax is a little lighter in weight than Sunbrella, but the latter has better visible-light stopping quality, and that’s a prime requirement of any awning. While WeatherMax claims to block 99 percent of ultraviolet (UV) rays, Sunbrella fabrics carry the Skin Cancer Foundation’s seal for recommended UV-protection products. We tested both using a UV-light meter and found that WeatherMax’s dark blue fabric allowed in a very slight amount of UV but none made it through the royal blue Sunbrella swatch. A sample of white, heavy acrylic fabric let in 20 percent more UV than both blue fabrics.

Many mistakenly assume that because a white shirt is cooler on a hot day than a dark blue shirt, an awning should be white in color. That would be true if white fabric offered the same protection from UV as darker colors, but it doesn’t. White actually allows much more visible light to penetrate the lighter-weight awning material. The result is significant heat buildup beneath the cover due to its semi-translucence and greenhouse effect. Darker colors in both Sunbrella and WeatherMax are better awning choices, though the ideal material would have a white surface and would be impervious to sunlight.

We had a full boat cover made from white Weathermax that turned green on the inside after 2 years. The company would NOT stand behind it. It totally disintegrated in six years. JUNK FABRIC!!!

Can anyone comment on Top Gun boat cover experience? Years ago I had a Top Gun auto cover and was very satisfied.

Sunbrella has relatively low abrasion resistance. Anywhere Sunbrella touches a hard point, it needs reinforcement. I’m interested in knowing if Top Gun has better abrasion resistance, an important feature in a boat cover.

tough