If only there was a good standardized 12-volt electrical connector. I’ve never had a boat without multiple connector failures, and most of them involved proprietary designs that were either platinum-priced or out of production.

The notorious cigarette lighter has long been the standard. It was designed for the single purpose of powering a pop-out lighter, but over time got enlisted for all kinds of connections—including powering handheld GPS receivers. They are bulky, low quality, impossible to waterproof, and lack positive engagement or positive restraint. Basically, they are a terrible design for anything other than a cigarette lighter.

While USB is standard in new cars and boats, and USB-C is rapidly becoming standard, amperage is severely limited and this is another connector that is designed for a dry locations. They can be waterproof when not in use and capped, but they are not designed to seal in use, and the connections are not waterproof when the charging port is opened.

There have been multiple attempts to standardize connectors for 12-volt accessories, but few have gained much traction in marine applications. Jones plugs (like a polarized 110V AC plug but smaller) were popular among electronics enthusiasts a few decades ago, but they didn’t lock and weren’t waterproof. Anderson Powerpole Connectors have many uses, but they are hard to waterproof and not really suited for exposed marine applications.

Motorcycles are rapidly moving to the DIN 4165 standard plugs (Powerlet is the best known brand) that look like a cross between a headphone jack and a cigarette lighter, but with improved weather sealing and a more secure connection between the plug and socket.

THE INSTIGATOR

Our investigation was triggered by a failed tiller pilot plug that was out of production; a direct replacement plug and socket set alone through eBay was one-third the price of a new tiller pilot. We also reasoned that if we could find something more standardized, we could use it for an emergency anchor light, cockpit lights, or fans. Sailors can dream can’t they?

WHAT WE TESTED

We rounded up a selection, including a generic DIN 4165 (Powerlet-style) plug, SAE standard 2- and 4-pole trailer light connectors, and multipole connectors from Sea-Dog, Perko, West Marine, Aquasignal and Szjelen.

HOW WE TESTED

We installed the sockets in a modified 5-gallon bucket (one of our go-to bench-test tools), sealed with the provided caps, energized, and exposed to a seawater spray daily for four weeks. This initial test was followed by more rigorous tests of the connectors with the caps removed.

VALUE GUIDE: Watertight Connectors

| MAKER | ZHOVEE | PERKO | AQUASIGNAL | CURT | MUYIMU | SEA-DOG $ | SZJELEN $ | WEST MARINE | SEA-DOG |

|---|---|---|---|---|---|---|---|---|---|

| MODEL/TYPE | DIN 4165 | 1189DPOCHR | 80100-7 | 57404 | SAE Sidewall port | SAE Sidewall port | four-pin | SAE 4-pin | Polarized Electrical Outlet 426234-1 |

| NUMBER OF POLES | 2 | 2 | 6 | 4 | 2 | 2 | 4 | 4 | 4 |

| BASIC MATERIAL | Plastic | Chrome-plated brass | Plastic | Plastic | Plastic | Plastic | Plastic | Chrome plated brass | Plastic |

| AMPS | 18 | 15 | 16 | 8 | 10 | 20 | 5 | 3 | 5 |

| FASTENERS | Back nut | Flange with screws | Flange with screws | Snap-in, 1/8-inch plate | Flange with screws | Flange with screws | Back nut | Flange with screws | Flange with screws |

| BENCH TEST | Yes | Field test | Field test | Yes | Yes | No | Yes | Yes | Yes |

| STRAIN RELIEF* | Partial | No | Partial | Yes | Yes | Yes | Partial | No | No |

| SEAL (ENERGIZED) | Poor | Good | Very Good | Poor | Poor | Poor | Excellent | Very Good | Very Good |

| CONNECTION TYPE | Spade | Screws | Screws | Crimp | Crimp | Crimp | Solder | Screws | Screws |

| PRICE** | $20 | $48 | $43 | $15 | $6 | $12 | $7 | $28 | $11 |

Note: Sea Dog Polarized Electrical Outlet is our Best Choice. $ indicates a Budget Buy.

OBSERVATIONS

None of the connectors leaked while they were capped during the first spray-test (four weeks), thus there was no corrosion or resistance increase. During the final test with the connectors open (without caps) the West Marine 4-pin connector developed minor tarnishing on the pins. Aquasignal, Sea- Dog and SAE pins appear to be tin plated. The others are brass alloys.

TECH TIP: Current Requirements

| EQUIPMENT | AMP RATING |

|---|---|

| TILLER PILOT | 1.5 amps |

| INCANDESCENT/HALOGEN MAST LIGHTS | 2-4 amps |

| LED MAST LIGHTS | 1 amp |

| INCANDESCENT/HALOGEN DECK LIGHT | 5-10 amps |

| LED DECK LIGHT | 1.5 amps |

| LED HANDHELD SPOTLIGHT | 5-10 amps |

| HALOGEN HANDHELD SPOTLIGHT | 15-20 amps |

Grease

Any 12-volt power connector will benefit greatly from a regular coating with anti-corrosion waterproof grease. We recommend Green Grease as a long-time top performer. (Yes, that is a brand, not just grease that is green. See “Conductive Greases vs. Corrosion.”) In fact, lightly grease all of the moving parts if you expect to be able to take any of them apart easily after long salt exposure.

Specifications

Check the amp rating and cable sizes. There is a considerable range of power rating, and if the cable does not fall in the recommended diameter range it will either leak or not fit.

Panel Thickness

Check maximum panel thickness; those with locking rings may not fit a normal deck. Can you get to the back side? Some of these can be installed from the panel side only, as long as you can fish the wires through. Others require access to tighten a locking ring. Some specify #5 flat head screws, which you will never find. It is simpler to drill up to #6, which is what we did. All can be wired from the outside.

Soldering

Soldering is easy in the shop, but some crazy situations requiring three hands can crop up in the field. I’ve been known to solder on short stubs and then crimp in the field. ABYC also states that solder may not be the only means of mechanical connection, leaving the Szjelen connector in limbo.

Do NOT solder the strands together before inserting into the set screw sockets. This is a big no-no. If the solder softens under high load, the wire will gradually work loose. Bootlace ferrules are acceptable if they don’t make the wire too fat for the sockets.

Protective Bonnets

If you can’t get the protective bonnet to seal properly to the exiting cable, you can always pump the bonnet full of sealant. Messy if you have to open it, but you shouldn’t. The Sea-Dog Polarized Connector was particularly good at fitting a wide range of cable sizes, including the oblong ROMEX cable— fine for branch wiring in homes, not for boats—that a prior owner had installed up the test boat mast (at least it was stranded wire). SAE and DIN plugs require splicing wires and covering with heat shrink.

Gasket

All of the connectors leaked using the factory deck gaskets. None of them leaked when we added bedding sealant. In all but a few exceptions, we got a better seal by eliminating the gasket and bedding the connectors with sealant. Exceptions would include the Sea-Dog and SAE connectors, which attach the connector cover to the gasket. We’d also keep the gasket on the Aqua Signal connector, since the gasket is needed to help retain the sealant on the very narrow flange. You might also consider cutting your own replacement gaskets out of a softer material, such as butyl rubber.

Connectors vs. Cable Pass Throughs

A connector is like a plug, with a low-pressure connection made that can potentially get wet and corrode. The attached device is easily unplugged and, importantly, it cannot leak or wick water into the cabin.

Pass throughs, on the other hand, make a water tight seal around the cable and the connection is inside the boat, typically near the cable entry. A mast, for example, can still be removed with wiring attached by sliding the wires through the pass through. However, these are only suitable for wires that will only rarely be disconnected. The rubber gasket will eventually harden and lose its seal over time. Commonly, they are not properly matched for the size of wire that is passing through. If the deck is cored, you’ll need to seal the core around the hole to prevent any leaks from migrating (see “Trouble Free Deck Hardware Installation”).

SEA-DOG

The large size makes it the easiest to install, with big screws and all external access. Downsides are no wire strain relief on the socket side and poor protection against cable rotation with smaller cables; a tighter grommet or sealant inside the boot would solve this. Use grease or Teflon pipe dope on the bonnet threads, since there is no gasket. If you need to remove the bonnet later, do it while the connectors are together; otherwise, there is nothing to hold onto during the twist.

Bottom line: Best Choice and Budget Buy. We put two of these on the boat for extended testing.

WEST MARINE

The strong, compact design is compromised by undersized terminal screws that are very hard to tighten sufficiently (mini-screwdriver) and no wire strain relief on the socket part. It was also the only sample that showed corrosion on the pins, and can be very difficult to disassemble once exposed to the elements for a few years. The sealing is good and the external strain relief is good.

Bottom line: Too many shortcomings.

ZHOVEE DIN 4165

More compact than cigarette lighters and with a snap-in engagement mechanism, both the sockets and devices designed for them are waterproof. They are designed for freshwater, not seawater, but we like the waterproofing, that they are DIN standard and increasingly common. There are only two poles, so they are not suitable for all applications, and because they don’t lock permanently into place, they are only for intermittent use.

It was the easiest to install, as long as you can access the locking ring on the back. Socket connections are crimpon quick-connects, which we like. The socket side is either connected to the device already, or you will have to solder it on or crimp it on and heat seal it yourself. Either works fine.

Bottom line: Recommended. We’re still not altogether sure about seawater, but it’s universal, passed our tests, and thus merits further investigation.

SZJELEN MULTI-PIN

Great sealing and a low price makes the Szjelen multi-pin an attractive option, but mechanical weakness and difficulty aligning the pins limit this to fixed instruments. A unique feature is that the wires must be connected via solder cups. Just dab with flux, strip and insert the wire, and apply heat to the long side. The solder sucks right in, resulting in a pro job every time.

What about ABYC compliance? On the plug side, the strain relief is excellent and serves as mechanical support. On the socket side you will need mechanical support. Of course, ABYC is a voluntary standard, and if used for electronics installation, there will be separate low-amp fuse. It looked safer than technically compliant sockets that have no better strain relief and tiny terminal screws.

Bottom line: Best Choice for low-amp electronics that won’t be moved often, like a chart plotter.

AQUA SIGNAL

This connector features a low profile, handles up to five pins, and offers excellent sealing … when new. We’ve had three of them on boats. One leaked into the cabin, a direct consequence of the socket’s thin sealing gasket and the lack of a flange on the socket for applying sealant. Others cracked, leaked, and shorted out internally after being lightly stepped on or snagged by a rope. They seem fragile and expensive.

Bottom line: Recommended for mast lights and instruments, if you can keep them from getting knocked around.

CURT SAE 4-WIRE FLAT

Commonly used for trailer lights, this connection seems vulnerable, but we’ve used these on saltwater boats for years. With generous use of grease, they have held up pretty well and have not been prone to sudden failure.

Each connector has its own short wires—pigtails—to connect to. It’s your choice to solder or to crimp your existing wires to these. The connectors are dirt cheap and they take only minutes to replace.

Downsides include difficulty joining a 4-wire flat cable to round cable and impossibility of mounting directly on a fiberglass hull (it can be mounted on a thin metal or FRP plate, which is then mounted to the hull).

Bottom line: Fine for trailers, this connector has little value on a boat.

MUYIMU SAE 2-WIRE FLAT

Like the 4-wire flat connector, the seal at the contact points isn’t great, but grease helps keep water out. Additionally, they meet the universal availability requirement. The bulkhead version tested came with a 4-screw mounting flange we thought we would like, but the plastic distorted over several months; you’ll need to go light on the screw tension.

Bottom line: The Sea-Dog version is a better choice.

SEA-DOG SAE 2-WIRE FLAT

This is similar to the Muyimu version but with a better flange and no leaks. We would have used this for our tiller pilot but we needed 3 pins. It is also available in a through-deck version (not tested), that will require access to the back side of the mounting surface for tightening the nut that secures the plug.

Bottom line: A Budget Buy for utility connections.

PERKO 2-PIN WATER TIGHT DECK CONNECTION

We had these on two boats, connecting portable solar panels and a tiller pilot. The plug has no screw or clip to secure it in place, and the connection itself is relatively loose. Within a few seasons, the connections became loose, creating higher resistance in the circuit.

Bottom Line: Not impressed.

CONCLUSIONS

We were hoping to find a universal solution, but had no such luck. We did find a few we’re going investigate further, with an eye toward swapping out all our old connectors with them. The Sea-Dog multi-pin is versatile, inexpensive, easy to replace, leak-proof, accepts a large range of cables, and they’ve been making them for a while. DIN 4165 plugs are going to replace cigarette lighter plugs, and they are waterproof enough to use in the cockpit. They are a standard design that will be around for a long time.

Waterproof grease is your friend. Apply Green Grease twice to the pins every year and your troubles will be few. It really helps with corrosion, helping even the cheap SAE plugs last.

We added USB outlets in the cabin for charging and a USB fan, but we consider those a dry location solution.

We’re done with cigarette lighters—get em’ out of here—but we’ll keep one in the cabin for a while, just for legacy accessories.

Rock-solid connections and corrosion resistant pins and sockets are the hallmarks of a waterproof connector.

Most of the manufacturers of the unions we tested relied on molded plastic for the body components. Although none of the plastic components failed in our test, experience tells that UV takes a toll on even the highest quality fiber-reinforced plastic.

The lower-grade metals (usually anodized aluminum or chrome-plated brass) used in other plugs have their own fatal flaw–corrosion. In most cases, however, it’s not the socket or plug body that fails first; the contacts succumb to corrosion. Although none of the contacts failed in our test, the early signs of corrosion appeared in some.

Whether you choose plastic or metal, best recourse is to locate the plug in a place where it is out of direct sunlight and is not exposed to direct spray and rain—and of course, is not situated where water pools.

Even the best-made connector will require routine cleaning, sealing, and protecting with anti-corrosion grease or sprays (see PS April 2017 “Conductive Greases Versus Corrosion,” and PS August 2007, “Practical Sailor Tests Spray-On Protection for Electronics and Electrical Systems).

1. Sea-Dog 4-pin metal body looks nearly identical to the West Marine model that we tested.

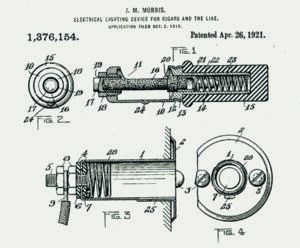

2. The two-pole Powerlet type connector (DIN 4165) provides broad contact area on both poles.

3. The Sea-Dog SAE 2-pin type kept water out.

4. SAE 4-wire sealed connector is familiar to trailer-sailors.

5. Aligning the threads on the Selzen mini-connector is tricky, but the seal is perfectly watertight.

6. Disassembled, the Selzen mini connector is ready for service

7. Selzen mini-connector showing terminals where exposed wire ends are inserted and soldered.

8. Hella offers a 2-pole DIN 4165 type connector that we did not test.

9. The West Marine and Sea-Dog, four pin connectors have a removable core, making it easy to insert the wire ends and pin them with individual set screws.

10. The metal West Marine plug and socket was in the minority.

11. After 60 days of intermittent spray exposure while capped, the West Marine connector shows no sign of internal corrosion.

Three rounds of test challenges couldn’t induce failure among the best watertight connectors

Since this was the first time Practical Sailor has done a this type of testing of waterproof sockets, we expected we might have to revise the test protocol as we learned more about the products and their capabilities.

Typically, in cases where no failures are observed and none of the products stand out as superior, we add additional, more rigorous tests.

In Phase One, the test sockets alone were installed in a modified 5-gallon bucket. They were then sealed with the provided caps, energized, and exposed to a seawater spray daily for 4 weeks. The seawater was not allowed to accumulate more than 1/16-inch deep and was allowed to dry.

Testers then poured in 2 inches deep and the bottom of the bucket was checked for leaks around the socket’s mounting gaskets. The sockets were examined for corrosion.

In Phase Two of testing, plugs were inserted into their respective sockets, and the seawater spray exposure extended for an additional 4 weeks. At this time the connections were tested for continuity and resistance under a 5 amp load.

After four weeks, the plugs were removed, and both the sockets and plugs were checked for corrosion.

In Phase Three, because testers detected no leaks in the caps, plug-socket connection, or bases, the caps were removed and the sockets were left with exposed to seawater (no current) for another four weeks, after which they were inspected for corrosion.

1. This view shows the bucket after the most severe part of the testing with the connector ends exposed.

2. The bottom of the bucket shows how sockets are mounted. Most sockets come with screw fasteners; we used nuts and bolts for added security.

3. An Inside view of the bucket shows caps to the connectors removed.

4. Aquasignal 5-pin plug after testing.

5. Sea-Dog 4-pin plug after testing.

6. West Marine 4-pin plug after testing.

7. Muyimu SAE 4-pin plug after testing.

8. Sea-Dog SAE 4-pin plug after testing.

9. Selzen 3-pin connector after testing.

10. Sea-Dog 4-pin socket after Phase 1.

11. SAE type 2-wire socket after Phase 1.

12. SAE Type four-wire after Phase 1.

This article was published on 27 July 2021 and has been updated.

So good to know that there is someone we can ask about the internal line temperatures of my running rigging. Or, “Holy Smokes!”

What about the NMEA 2000 connectors? I think that is what Torqeedo uses for both power and control cables.

Great article!

We cannot avoid using through deck/superstructure connectors at many areas. In my experience they all fail at some point, either mechanically or by corrosion and sealers failure. I think my present boat builder (Contest, NL) provides a good solution with a goose neck stainless tube (40mm) by the deck stepped mast and on the aft deck above the transom for all the wiring there.

All the connections are made inside the boat above the headboards and after 30 years of service still look like new. Happy to provide a picture if interested.

Most of what you tested is junk. Look for connector manufacturers like Amphenol, Deutsch, TE Connectivity, ITT Cannon, Bulgin, Conxall, etc. A place to start is online at Newark Electronics. Check out plastic Mil Spec circular equivalents and other connectors designed and tested for harsh vehicle, agricultural, and off road applications. Reliable connectors for the marine environment are available but generally not from “marine” distributors. And they are not cheap!

Thanks for the options; maybe you should be a magazine editor!

Careless editing: Picture 7 is not related to its caption.

Since in every case, the cost of a failure, plus diagnosis, plus a fix, is much greater than that of the connector, PS does us no favors by testing junk. Find sources for good connectors, show us what they look like, and test them against real sea water. Only then can we drive the market to quality with informed purchases.

20 years ago, I got disgusted with all the commercial alternatives, and bought some Mil-spec connectors. They are available in a wide variety of pin configurations, from 3 or four up to 61 circuits, and for currents up to 30 A. They also come in versions for bulkhead mount or cable mount, and with solder or crimp pins. The army uses them, and they have to work in extreme conditions. Kind of pricey, but not outrageous considering the problem solved. I’ve had no problems in 20 years. One of them by the way is on the foredeck for the windlass, and has regularly been seawater immersed from waves over the bow. Previously, I had to replace connectors every 2-3 years.

Automotive connectors have come a long way in the last ten year with the ever increasing electronics control of virtually every system. Most of these connectors are weather tight , reliable and cost effective and made by companies that know how to make connectors …not the junk you tested 🙂 In this vein, a very cost effective reliable weather tight connector series made by a reputable manufacturer are the the Deutsch DT series connectors these are available with both crimp and solder pins. ..BUT Crimp is ALWAYS the preferred connection method.

I have had very good luck with dielectric (bulb) grease. A 3 oz tube is $10. The stuff is purpose made for connectors. Green grease is less expensive per once, but comes in larger containers, so the outlay is more. Use the stuff on every electric connection and socket on the boat.