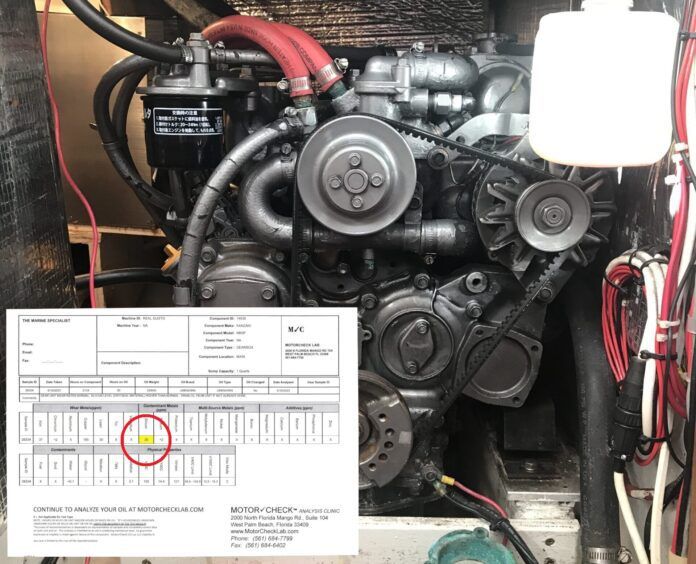

We’ve all heard that if you give a diesel good clean fuel, keep it cool, and stay on top of the oil changes, its life span in a boat can be as much as 10,000 hours.

But what if you are considering buying a boat and the condition and history of that engine are unknown? You have no way of knowing if the oil was changed regularly, if the engine overheated, or if the bearings are worn. Maybe you just want to know the health of your current boat’s engine. After all, a diesel engine is one of the most important and expensive pieces of equipment on a sailboat.

Engine oil allows us to peek inside the engine; taking a sample of oil from a diesel engine and sending that sample into a lab for testing offers a way to know the condition of an engine. (See link)

The lab tests the oil in the following ways:

Testing the Flashpoint: Oil is heated and the temperature is recorded at flashpoint. This shows us if there is diesel present; diesel in the oil indicates an injector or compression issue.

Testing Insolubles: A centrifuge spins oil into a cone-shaped test tube, and the solids that have accumulated are measured for comparison to other engines.

The Spectrometer: This is where the real magic comes in. A spectrometer detects how many wear metals are present, showing how the engine—specifically the bearings—are wearing. It also shows contaminants such as coolant, saltwater, or other additive elements.

Viscometer: This shows the grade or viscosity of the oil at operating temperature.

ALL WILL BE REVEALED

Having your oil analyzed is easy. A sample container can be ordered from Blackstone Laboratories. There are many other lab choices that may be worth checking out but for the price and the testing that was offered, I chose Blackstone.

When you order the envelope, you pay for the sample processing on their website. At this time, the cost is $35. A package that contains the necessary containers to ship back the oil sample is sent to you usually within a week. Included in the kit is a pre-paid postage envelope for sending your sample oil to Blackstone.

There is a form to be filled out which lets them know the basics about your engine such as the make and model, estimated hours, use (marine or fresh water) as well as a place for any additional notes or questions you may have. The sample can be taken at any time, with or without an oil change, so long as the oil has been used and the sample is free of outside contaminants.

Take your sample from an engine that has been warmed up. Usually 15 minutes should be enough to burn off any residual diesel from when the engine was last run.

Use a pump and push through enough hot oil to cycle out any old oil from previous oil changes.

It’s easy to contaminate test oil. Using a funnel that was previously used to fill coolant or using a pump that was used to change oil from another engine could yield inaccurate results. It might be a good idea to use a new clean pump if you don’t have a dedicated oil change pump on board.

After taking the sample, check the dipstick and add oil back to the engine as necessary. Follow the instructions from the sample kit on packaging the oil and sending it off for analysis.

A sample sent through the US mail takes 2-3 weeks to be processed.

If you need a faster turnaround you can overnight your sample to Blackstone. They usually process these samples within a day or two. Overnight postage is not cheap, but that is the only extra cost for a quick turnaround service. Blackstone does not charge extra for this.

Your Oil Report

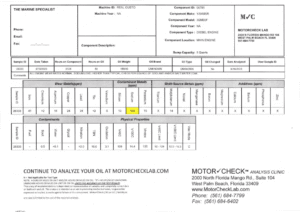

We’ll look at each test point and explain what was tested, what the results mean and how to go about using the information.

At the top of the report, we see that this is a Yanmar 3GM30F that had 3124 hours on the engine and oil had about 50 hours of use.

Here is what the oil analysis measured:

Metal levels Iron – The iron levels in this Yanmar engine were normal. There were no issues with the crank shaft, cam shaft and block. Iron is found in all of these components and if iron levels become higher than normal, it can indicate a major mechanical problem.

Chromium – This metal is found in piston rings which looked to be in good shape – nothing unusual here.

Aluminum – The pistons were not shedding metal. This engine did not have a turbo however for engines that do, elevated aluminum levels can be a sign of turbo trouble.

Copper, Lead and Tin – These metals show bearing wear and appeared normal in the sample.

Silicon – Nothing out of the ordinary; Normal levels show no issues with dirt or sealants inside the engine.

Sodium – An issue was found. As called out on the report, a high sodium level shows additive, coolant and/or saltwater is in the engine oil. More on this later.

Potassium – Potassium levels were normal. Sodium and potassium are corrosion inhibitors found in coolant. Seawater has about 40 times more sodium than potassium so low potassium levels with high sodium levels point to potential saltwater contamination. This means coolant is unlikely to be the source of the sodium.

Contaminants Fuel – Diesel fuel levels in the oil were low. The injectors were properly atomizing diesel and there were no combustion issues.

Water – This level was low. A hot engine burns off water. It’s a good idea to run an engine up to temperature every couple of weeks. Running the engine removes any condensation build-up and a hot engine also can evaporate seawater, Sodium does not evaporate and would be left behind.

Soot- Another item which shows normal levels, this is evidence of complete fuel burn.

Glycol – These levels were low. Glycol is found in coolant and a low level hints that the sodium found in the oil was likely not from coolant.

Physical Properties Nitration – This tested as normal, indicating this was not deteriorating the oil.

TBN – These levels were above the minimum base of “3” which was good. TBN is a measure an oils alkaline base reserve. This demonstrates that the oil could neutralize acidic contaminants.

Oxidation – This measures how oxygen is reacting to the oil from either being run at high temperatures or for an extended amount of time. This was within spec.

Viscosity – This is tested at different temperatures to measure how well the oil can lubricate. The viscosity of the oil was within the limits.

Using Information in the report the first recommendation would be to drain the oil and get the elevated sodium level out of the engine’s oil. The question becomes, why was excess sodium in the oil?

We would need to couple this report with an inspection of the engine and find out how the extra sodium got there.

What are we looking for: Is the raw water pump cam driven? A seal between the raw water pump and cam could allow seawater in. Looking at the inside of the pump behind the impeller could also show a leak. There might be oil seeping into the water pump which is a sign of a bad seal.

Was water backing up in the exhaust? Inspecting the exhaust elbow and look for carbon build up, corroded metals or leaking parts. It would be worth pulling the elbow to check this out.

Was the exhaust loop high enough?

Were there any blockage or problems with the anti siphon valve if present? Was saltwater entering the engine through the air intake?

If the engine is difficult to start, this may be the problem. This model Yanmar uses an intake silencer to filter intake air and quiet the engine noise. Look for signs of water on whatever is above the engine and check out the air cleaner. If the top of the engine is showing rust, it’s important to find out why.

Saltwater does not enter the block on this model engine unless it mixes with the coolant through a break in the heat exchanger.

We don’t see elevated potassium levels so this makes a head gasket leak less likely. Lastly, and it would be great if it was the reason for elevated sodium levels: Was salt residue in any funnel or container that the oil sample came in contact with?

It’s important to ensure when taking a sample that no contaminants are introduced. After all this, if the answer is not clear, it’s time to reach out to a mechanic.

Professionals see issues like this regularly and they should be able to identify the cause.

Once the problem has been identified and fixed, it is recommended to re-sample the oil in 50 or so hours to confirm that the issue has been resolved. This oil sample report gave us a snapshot of a healthy engine.

A contaminant above the norm was found. Like preventative maintenance, using oil analysis can identify problems early, saving time and money. It’s a tool that can lead us to a problem that needs attention. If nothing else, oil analysis can offer some peace of mind.

Wouldn’t it be great to know all those oil changes and maintenance routines are paying off?

Potassium is not used in all or even most coolants. You would have to test the coolant to make a connection. Coolant analysis is another, related topic. Exhaust-to-coolant leakage problems can often be detected more easily that way as well, due to changes in the coolant.

Another source of coolant contamination is leaking cylinder sleeve O-rings or sleeve perforation. Was a nitrited coolant used through the life of the engine? Google diesel coolant cavitation liner.

But the lack of glycol makes a coolant leak seem less likely.

A good summary. I ran an oil and coolant lab in a former life.

The test appears to be reasonably priced. More questions arise as to what you do with this information and the expertise of the individual telling you what it all means. I’m not sure your neighborhood mechanic would qualify and surely charge many times the cost of this test to act upon the results. I see it somewhat like medical tests I have taken where even my doctor depends on a specialist to interpret the data.

This article is good for bringing a non-professional up to speed about this important data.