Were guessing 90 percent of sailors have their boat hauled by a yard. A travel lift or crane plucks the boat from the water, and yard guys block the boat for the winter. Your sole involvement is reading a warning in the lease agreement that you will not touch the stands and that you will not attach anything to them, including tarps. Those are good rules, and nothing we are about to say is meant to contradict them.

On the other hand, some of you will need to have stands repositioned to perform bottom work. The yard will do the moving, but its helpful if you understood what they can and cannot do. Some of you will trailer your boat home for the winter. Maybe it will stay on the trailer, but maybe you want or need to move it off to get the work done.

You need to know how to work safely. A few of you will have the boat transported home by hydraulic trailer and blocked by pros; very handy if you have a lot of work to do. But you will need to buy the stands and know how to move them when needed (remember to buy an extra pair-this is required to move them safely).

Safe Practice

Most of the weight should be on wooden blocks, with the stands serving only for balance. Additionally, substantial weight on the keel prevents shifting of the keel in a beam wind. According to ABYC, there should be at least two blocking points; a single blocking point can allow the boat to rock fore and aft.

Never block the keel more than 2 blocks high, and one is much better. Boats 30 feet or less can use several solid wooden blocks 4 x 4 x 18 inches. Boats 31-40 feet should use 6 x 6 x 18-inch blocks, and boats 40 feet or longer should us 8 x 8 x 18-inch blocks not more than 5 feet apart.

The American Boat and Yacht Council is explicit about how jackstands should be used for recreational craft. The stands should be spaced no more than 10 feet apart, with the forward-most and after-most pairs of stands no more than 10 feet from the ends of the waterline. Powerboat stands should be set with the aft pair placed as close to the aft end of the waterline as structure permits, and spaced no more than 10 feet apart.

The boat must be vertical. The angled stands are there only to provide balance. The boats weight should be borne by the blocking. Do not use stands to support the weight of the boat, other than keel stands specifically designed for this purpose. Some boats require that the weight of the boat be supported on the chine. Use supports designed for this load.

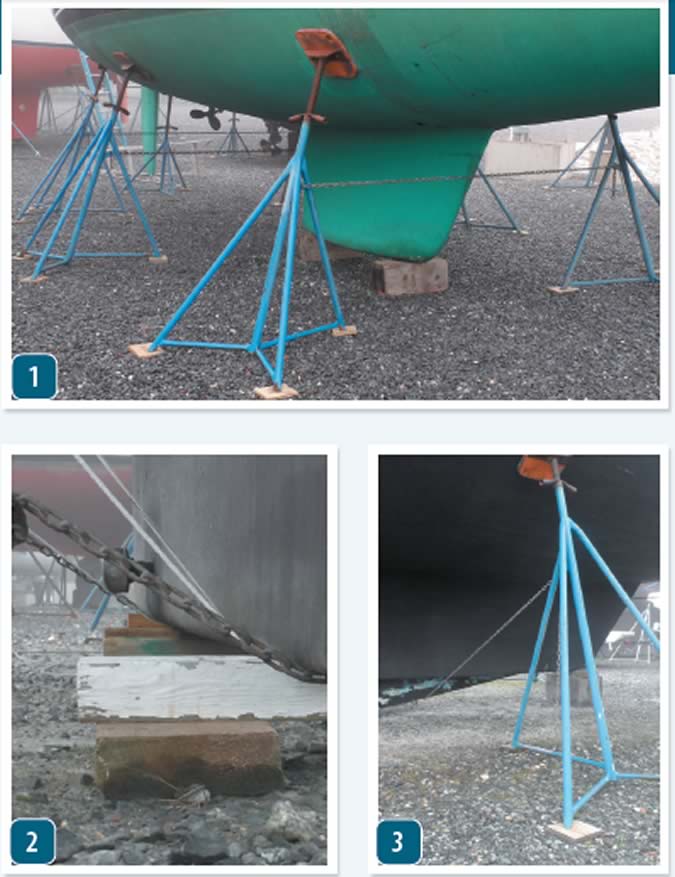

Install stands as far outboard as practical and with the adjusting screw as close to perpendicular to the hull as practical. Sometimes it is necessary to tip the stand to make it perpendicular to the hull. Do not block more than two legs of a stand.

On vessels with extreme overhang, forward or aft, a stand should be placed under the overhang perpendicular to the centerline. Do not place blocks on top of boat stands to increase their reach. Stands should not be used as jacks to raise or lower the boat. Apply boat stand(s) so that, after the blocking operation is complete, the stand screw can still be adjusted up and down.

Secure each pair of stands across the boat with chains (3/16-inch minimum) to prevent the stands from sliding out. The material used to tie the stands together should be at least 3/16-inch chain. Rope or wire is not recommended because it can stretch and allow the stands to slip. Do not tie anything to the stands; for example, wind catching under a tarp can tip a stand.

The procedure for placing stands is this:

- Place the boat on the keel blocks, using flat wooden shims to get a good fit.

- Place the first set of jacks near the center.

- Connect the jacks with chain. There is a slot to drop the chain in.

- Slide the jacks apart until the chain is TIGHT. Place plywood pads under the feet to prevent sinking. Use pads on paving, too, as stands can slide.

- Tighten the jacks. The handles should be quite snug, but additional leverage is not required. Placed using this sequence, the jacks AND the chain are tight.

- Avoid placing chains under centerboard casings if possible. There may be work to be done in this area.

- Avoid placing chains under fin keels; space the stands so that the chains are in front and behind.

- Bow stands are not typically chained. Powerboat stands are often not chained, but they should be unless located on a flat chine.

- Repeat for each stand pair.

In other words, stand pairs must be linked with chain BEFORE the jacks are tightened. This ensures that the chain and jack pair are tightened as a unit and will not shift or loosening when the wind blows.

Boats on Trailers

Many DIYs would love to lift the boat off the trailer to make work more accessible. Our first advice is don’t. The safety concerns are real. If you need the boat off the trailer and on stands for access, consider having it delivered by hydraulic trailer and blocked by pros.

Small boats can be jacked a few inches by manipulating the trailer. Drop the trailer tongue to the ground and block the transom. Raise the tongue and block the bow. Then insert intermediate blocks, either 2x4s or 4x4s, on top of the bunks (a minimum of three on each side) for safety. The parts of the bottom you missed can now be scratch sanded and painted using extensions. Never place any part of your body where the boat can drop on it.

If the boat is on rollers, shifting the boat fore and aft can provide access, but don’t go so far as to make the trailer unstable; they can tip. Place solid blocks under the trailer frame before shifting the boat. Some boats have adjustable bunk boards that can be lowered, but alternative support must be provided.

In other cases, it may be necessary to remove the trailer. We can remove our trimaran from the trailer using four jacks. We extend the two floats outwards, jack the boat clear of the trailer using motorboat jacks with V-tops, and the slowly pull the trailer out. We then place two motorboat stands under the keel for security before work begins. The primary rules are to never jack the boat more than a few inches above the trailer and to keep your body clear. If there is ANY doubt, leave boat moving and blocking to professionals.

Lifting Capacity

Some very light boats and multihulls (under 4,000 pounds) can be lifted a few inches using motor boat or keel stands. The American Boat and Yacht Council (ABYC) does not advise this, but it can be done if appropriate precautions are taken. Grease the threads liberally with heavy waterproof grease. Lifting 1,000 pounds requires about 250 inch-pounds of torque, which can be applied by pulling hard on the handles. Do not add apply additional leverage. We don’t recommend lifting more than 1,000 pounds with a stand, as the threads will gall. If the hull flexes, stop.

Moving Stands

Why would you ever move a stand? Painting under the pads is one reason. However, solvent-based antifouling paint dries very quickly, so it is accepted practice to touch-up the pad spots while the boat is hanging in the slings prior to launch. It will dry some in the 15 minutes it takes to get the boat to the water, and it will finish curing in the water.

Weve been doing this for 40 years without failure, and we patrolled the boat yards heavily, looking for any evidence of pad spots on boats coming out after 1-2 years. Weve never seen convincing bad spots, so were convinced its not worth moving the stands.

Water-based paint, on the other hand, takes as much as 24 hours to dry, or certainly at least 6 hours on a hot, dry day, and its not going to finish drying underwater. Moving the stands can be a good idea, or at least hanging in the slings over the lunch break, if possible.

Perhaps your bottom work is more extensive, including blister repair, a gelcoat peel, or fairing. If you plan to work on the bottom of the keel, encourage the yard to use low-profile keel stands; otherwise the only way to access the bottom is to have a travel lift pick the boat, which will cost about $150/hour. One yard quoted $3/foot to reblock.

Check stands routinely during storage season. The hull may begin to flex under the stand pad; move the stand so that it bears directly on a bulkhead and add additional stand pairs as be needed. Always install a new stand pair before moving the old pair. Watch for settling. Even with wooden pads under the feet, freeze/thaw cycling or poor ground can result in settling. In some cases, larger pads are needed, and perhaps more stands.

If you notice any of these conditions, bring it to the yards attention. They should fix it without charge. While youre at it, check a few boats on either side; just as preparing to weather a storm in a slip, if one boat comes loose, were all in the soup together.

Stand Details

For 95 percent of monohull blocking, solid wooden blocks support the keel, and angled boat stands connected with chains keep the boat in balance. However, there are a few exceptions:

Keel stands. These squat stands can replace wooden blocks and are handy if the blocking must be moved to accommodate keel work, such as fairing. We wish more yards had them available, but blocks are cheaper. It could make sense to buy your own if you have a bunch of work to do on the keel. However, remember that these cannot be removed entirely to work on the keel. As with side stands, another load bearing stand must replace each one that is moved, and side stands should never carry the weight of the boat.

Motorboat stands. These are for flatter bottoms, and are used on multi-hulls to support the amas and keels, since side braces are not needed. These are often used in place of keel stands for centerboard-equipped boats, and used under the bridge decks of catamarans.

Top pads. The stand prices in the value guide include a top pad. However, it is sometimes advisable to use a different pad. For example, V-tops are used in conjunction with angled sailboat stands under the bow, and V-tops are used with motorboat stands under some multihulls, depending on the hull profile. Top pads are all interchangeable and just drop in. The top includes the threaded jack rod and handle.

Anytime a side stand is moved, a new stand pair must be installed first. This means you will need one extra pair of stands. Anytime a motor boat stand is moved, install a new one first.

Products

All manufacturers make a variety of stands, as described above. They also make stands used to support trailered boats for yard work. These are not reviewed here. Load ratings vary because manufacturers use different safety factors. We found no stories of stands failing, even in hurricanes, only stories of stands that slid out of position due to improper placement or extreme winds.

Brownell Boat Stands

For most people in North America, Brownell is the most familiar name in boatstands. All of the stands in the yards we visited for this report were made by Brownell. An innovator in the field since 1954, Brownell is now under new ownership. Heavily built, Brownell stands last a long time if you remember to grease the threads each year. The nesting design comes in handy for storage when sailing season begins.

Bottom line: As the industry standard in the U.S. and Canada (with distribution in Australia and Scandinavia), they are our Best Choice.

Marine Mart

These are faithful copies of Brownell, we don’t know if there is a difference in durability, but they seem very similar and are considerably cheaper.

Bottom line: A Budget Buy if Brownell isn’t at close at hand.

Hostar Marine

Made from angle iron instead of pipe, this gives them more bearing surface on soft ground. They might also be more prone to skidding. The top chain arrangement might not stabilize the base of the stand as well, allowing movement. We might add a second chain down low. Popular in the Great Lakes region, less so on the coasts.

Bottom line: These sailboat stands are a good buy, but watch for corrosion.

Kropf Industrial

Much like the Hostar stands, these are fabricated from angle iron. We have not seen these in the field. It bugged us that the web page examples of sail boat blocking included critical errors.

Bottom line: We’ve not been able to evaluate these stands, but we did notice some poor examples of blocking on its website.

No-name stands pop up on eBay from time to time. We can’t see risking a purchase. Used stands are sometimes available on-line. They sell quickly for high prices. If you see a bargain Brownell advertised on-line, its worth investigating. When you no longer need your stands, they will sell easily.

Conclusions

We’ve seen the aftermath of fallen boats. Its not pretty. Blocking is quite safe, if the blocks are solid, and the stands are properly placed and chained. So safe, its easy to take it for granted, but don’t. Watch the yard workers work, see how it is done, and then let the yard guys move stands for painting. It is a strict lease requirement in any event. Do check on the stands a few times during the off season, looking for signs of settlement or loosening, but let the yard workers fix it.

If you have a trailered boat you take home for the winter, jacking of lighter boats is not out outside the range of DIY possibilities, but think it through and don’t make mistakes. People get crushed. An old millright we worked with told me that If anything strains, something is wrong. Something is going to get broken or someone is going to get hurt. The work must be meticulous and it must look and feel easy. Adhere to ABYC practices and avoid home-built stands.

We covered a thing or two about blocking boats. But, be careful and don’t run out and bite off more than you can chew. In most cases, this is a job for professionals.

Jacks is critical. The chain should be connected before you begin adjustment, or the jacks will not be snug. When tightening, the handles should be quite snug, additional leverage should not be not required. If the chain is connected after the jacks are tightened, there is a greater chance of a jackstand moving out of place.

- Dont forget the pads under the feet. This yard has very firmly rolled gravel over hard clay, but many coastal yards are built on mush. The keel blocks are nice and solid.

- Planks should not span open space. If any rot sets in the keel could drop, placing the entire blocking scheme in jeopardy.

- Keep chains clear of the centerboard. Makes service a little tricky.

If only this article had a good editor.

and proofreader: An old millwrite we worked

but, you swore me off of trying to lift boat off trailer with stands, for that, thanks

It appears there is a more general need for proofreader(s). Re: the March 2020 cover – Savvy is not spelled “Saavy”.

It’s millwright.