Three Common Errors Made With Boat Electrical Systems

Page 7

Three Common Errors Made in Boat Electrical Systems

Boats with AC power systems continue to give their owners problems. Many of these problems are avoidable, and some are deadly. The major problem in using power from shore is that the risk of lethal shock is substantially greater in and around a boat than it is in a house. Moreover, the nature of the shock hazard changes when the boat is moved from freshwater into saltwater.

An AC electrical system must be designed and installed on the boat in such a way that the crew and any nearby swimmers are protected, no matter what kind of water is underneath your hull. Any stray current in the system will always work its way back to the source of power. And when you tie into shore power, its going to head for the AC ground that is established somewhere up on shore, possibly hundreds of feet away. The return point for shorepower is a conductive rod driven into the earth. All leaking current heads for the driven rod.

When it comes to shorepower systems, its a serious mistake to treat a boat like a floating house. The electrical standards established by the American Boat and Yacht Council (ABYC) clearly indicate that you should handle the entire boat as a grounded-type portable tool. Never ground both the hot wire and the shore-grounded neutral on the boat. The three most common errors boat owners make are: (1) connecting the grounded neutral (white wire) to the grounding wire (green wire); (2) omitting (or cutting) the green grounding wire connection to the engine; and (3) using equipment that requires both alternating and direct current, and which is not specifically designed for use in a marine environment. Making these mistakes can be very serious, if not disastrous.

For more details these common errors and other wiring advice, purchase Marine Electrical Systems, Volume 5, AC Systems from Practical Sailor.

Or, buy the entire Marine Electrical Systems five-part series!

Avoiding AC Shore Power Cord Problems

Page 12

Shore Power Cords

One of the often overlooked maintenance items in the pre-season rush to the water is the AC shorepower system. Barring improper use or some owner fabricated MacGyverism gone bad (jury-rigged adaptors, botched plug installations, etc.) overheating and corrosion are the primary causes of AC shore power cord problems. Charred plugs and receptacles are the most common and are a result of resistance build up due to loose or corroded connections, which in turn generate heat and the potential for fire. The problem is especially prevalent among boats that continually run high energy loads such as water heaters and air conditioning units.

Basic inspections of your AC shore power system are easily accomplished and are well within the ability of any boater. The first step is securing all AC power to avoid accidental shock hazards. Turn off your boats main AC breaker, then the shore pedestal breaker. Next unplug the shore power cord and verify that all other sources of power (such as power on-demand generators and DC to AC inverters) are turned off and their respective breakers secured in the off position.

Start your inspection with the shore power cord itself, ensuring its constructed of proper marine grade components, uses appropriately sized wiring, and is the shortest cord that will get the job done. Always replace cords that show signs of chafe, cracks, split insulation, or those having electrical tape repairs.

Industry standards call for shore cords to have molded-on plugs with sealing flanges or appropriate weatherproof boots. The plugs themselves should be checked each time you disconnect shore power (prior to getting underway for example) or monthly at a minimum, particularly for discoloration or corrosion on or around pins and plug inlets.

By the time discoloration is visible at the front of a plug or inlet, youll typically find that the damage is greater upon opening up the back for inspection. If left uncorrected, the damage will snowball (due to increasing resistance and heat buildup) until it burns a hole through the face of the plug, possibly leading to a fire.

When inspecting your shore power cord its also crucial to check the dock pedestal outlet and your boats inlet receptacle, ensuring both are corrosion free and undamaged. Upon finding a charred power cord plug, many owners simply replace it or the cord itself, only to find the new one also damaged a short time later due to a burned dock receptacle or inlet.

Another good practice is checking the feel of the connection when plugging in. Those that feel loose or don't seem to be making firm mechanical contact likely wont provide good electrical contact either. Avoid using worn or damaged pedestal plugs and report them to marina personal as soon as possible.

For more advice on electrical safety aboard, purchase Marine Electrical Systems, Volume 5, AC Systems from Practical Sailor.

Or, buy the entire Marine Electrical Systems five-part series!

Using an On-Board Generator To Power Your AC

Air conditioning aboard is seldom a problem when you're plugged into shorepower. The difficulties arise when it gets hot and you're underway. Your battery bank and inverter, which do such a nice job for your stereo and your lights, are just not up to the demands for 110-volt AC electricity that an air conditioner or other power-hungry large appliance requires.

The answer? An on-board generator set. A number of modest power output generator sets in sizes suitable for boats as small as 25' to 30' in length are available.

GENERAL CONSIDERATIONS

First, your choice of genset depends on the type of engine you use for propulsion. In other words, if you run your genset on the same type of fuel that you use for your main engine; this simplifies fuel storage, not to mention fueling-up. The same pros and cons of gas vs. diesel in general apply here: Gas engines are cheaper to buy, but cost more to run, are quieter but will give out sooner, etc. Most of the gensets covered in this article are powered by water-cooled engines.

Air-cooled diesel and gasoline generator sets are available, but, with few exceptions, these units are not intended for use on a boat. Some specialized air-cooled diesel engine-powered DC generator sets are available, usually in combination with direct mechanical power drive for such loads as refrigeration compressors and reverse osmosis watermakers. A few manufacturers also make small water-cooled DC generator sets which can be used to provide 100 amperes or more of 12-volt current, allowing operation of modest capacity air conditioners.

HOW BIG A GENSET?

Your first question should be: "Do I need a genset?" The answer is that you do if you run on-board air conditioning, or your boat has huge electrical demands. Otherwise, simplify your life, skip the plumbing and exhaust installations, and save (a great deal of) weight by going with an inverter instead. How big a genset your boat requires depends on the amount of electrical power needed. It is tempting to choose either too little or too much. On the side of too little is the obvious advantage of smaller size, weight, and cost. At the other extreme is the desire to simultaneously power every device on the boat. The best choice usually lies somewhere in between. A good starting point is to estimate your power requirements. Google search "electrical load calculator" or "estimating marine generator loads" and you come up with several sites with calculators that let you input your AC loads to come up with an approximation of peak loads.

Control of most modern, multi-unit, A/C systems can be coordinated to prevent simultaneous starting of compressors. This can be important, because the in-rush current required to start the compressor is a multiple of the running current. Load shedding - avoiding simultaneous use of the toaster, electric coffee pot, electric skillet, and hair dryer when all A/C systems are on - is an intelligent way to keep the maximum needed generating capacity within reason.

When sizing a genset, use the continuous kW rating of the genset rather than the peak kW or kVa rating.

For more advice on the selection and installation of a genset, purchase Marine Electrical Systems, Volume 5, AC Systems from Practical Sailor. Or, buy the entire Marine Electrical Systems five-part series!

Gel Batteries – Are They Right for Your Boat?

Gel Batteries

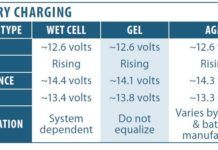

Gel-cell technology has been around for a number of years now. But the batteries got off to a bad start, largely due to promises of life cycling that were too optimistic. Even worse, there was little or no warning of the voltage limits of the battery (they must be charged at no more than about 14.1 volts). We know many sailors who bought gel cells expecting great performance, installed them in a boat with the standard battery charger (that charges at more than 14.1 volts), then wondered why the batteries failed after just a few weeks.

All gel batteries are not created equal. The big three gel manufacturers- EastPenn, Johnson Controls and Exide-differ remarkably in how they make their products and what they put into them. Gel cells differ considerably from their wet-cell counterparts in that the grid inside is made of calcium/copper alloy. Calcium may be used in starting batteries to enable the battery to give up large amounts of energy for short periods of time, but is less desirable for deep cycling.

How do the gel cells get away with it and why do they use calcium? The first reason is the ability of the battery to use the power from the gelled electrolyte, which has the consistency of wax, instead of taking it from the plates. The plates are not stressed as much in this manner. Secondly, calcium is a very low-resistance material and allows the gel cell to accept a higher rate of charge in the beginning of the charge cycle. Thirdly, gel batteries have the ability to sit for very long periods of time with very little self discharge, even in warm temperatures. In taking the cells apart, it was interesting to note that these batteries continued to show voltage on our meter, owing to the power being stored in the gel mixture, even with most of the internal cells severely cut away.

Another asset of the gel battery is its ability to be sit on its side or end, solving battery space problems, but expect up to a 10% loss of performance. In a pinch, a gel cell could even be built into a semi-dry bilge as it is totally sealed via its special cell caps and operates at a positive internal pressure of up to l-l/2 psi, thus the puckered look of the case assembly at times.

Gel batteries never need maintenance. Their recombination technique replaces the lost moisture in the battery as long as the integrity of the closed cell is intact. A sure way to destroy the battery is to overcharge it, which drives out the oxygen and hydrogen via the cap; the result will be a dried out cell. All gel cell battery manufactures recommend special charging procedures with particular attention to the final charging voltages. And yes, gel batteries do make good starting batteries.

For more information on marine batteries and other electrical systems, purchase Marine Electrical Systems, Volume 1, Batteries from Practical Sailor.

Or, buy the entire Marine Electrical Systems five-part series!

Choosing Marine Cleaning Products With the Right pH Level

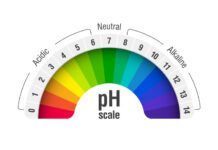

When choosing a multi-purpose cleaning product, its a good idea to look for one where the pH level is balanced so that it is an effective cleaner but isn't so strong that it will harm the surface being cleaned. This is especially important if the surface has a sealant or wax coating.

The pH scale runs from zero to 14. The mid point of the range, 7, is considered neutral; pure water is a neutral liquid. Liquids that have a pH higher than 7 are considered to be basic, or alkaline; most hand soaps and bleach are alkaline cleaners. Basic or alkaline cleaners do well at removing oils and fats, so if youre looking to degrease your engine, try a cleaner with a high pH.

Solutions with pH levels measuring zero to 6 are considered acidic; coffee, sodas, and lemon juice are examples. Acids break down difficult stains, making them easier to remove. So if youre looking to get some rust off your deck or scrub away a waterline stain, a cleaner with a low pH will do a better job than one with a high pH. Anytime you use an acidic cleaner, however, be sure to rinse the area being cleaned with fresh water afterward.

For more on the right cleaner for the specific job on your boat, purchase and download Essential Marine Cleaners today!

To read even more about the cleaning and maintenance of all your boating surfaces, buy the entire three-part series for the price of two! Available for purchase and download is Practical Sailor's ebook series, MARINE CLEANERS. This three volume set contains the ebooks GELCOAT MAINTENANCE AND RESTORATION, ESSENTIAL MARINE CLEANERS and SPECIALTY MARINE CLEANERS.

You'll get one complete ebook FREE.