Delighted with the performance of the over-the-boom riding sail, we decided to make our own.

To measure, we outlined the proposed sail area with -inch rope and measurer the resulting edge lengths. The rope ran from starboard stern cleat, over the boom (raised 30 degrees) to the port cleat, and then forward about 75 percent of the length of the boom, and down to the starboard cleat again. The forward corner was secured to the mast with a length of line.

The lines were then lashed together at a point about shoulder high to simulate the clew position, making sure the sheet angle bisected the proposed clew angle. Because each boat behaves differently at anchor, consider using a polyethylene tarp to build a mock-up.

You can reduce the area of a large sail by narrowing the Y or V or lowering the boom, but a smaller sail will be more robust in strong winds. The corners should be reinforced like any jib. Because the riding sail might be used in very strong winds, use storm weight sailcloth and stitch rugged hems that are at least 1.5 to 2 inches wide, or reinforce all edges with webbing. Corner patches must be heavy. All riding sails are cut flat, with no broadseam.

Conventional sail kits are available from Sailrite (www.sailrite.com). When measuring be careful your chosen design it does not interfere with your bimini or dodger and be sure to confirm the forward clew angle.

A note on fabrics. Although polyester (Dacron) sailcloth has coatings that provide UV protection, no sail material is impervious to the sun. Unprotected Dacron will begin to fail within three years of continuous exposure. Top Gun and Sunbrella have more UV resistance, but they stretch-and Sunbrella is vulnerable to chafe. PS is currently researching paints for UV protection of sails, but final results will not be available for several years.

Our provisional suggestion is Amazon Inflatable Paint in gray. For use at anchor we would use the same weight sailcloth as used on the mainsail. For use on a mooring we recommend increasing the fabric weight and painting the sail for UV protection.

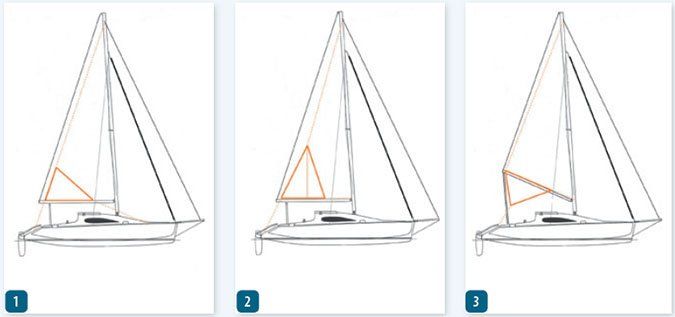

I misunderstood the design and from Pic #2 I thought the riding sail had a spine between the front triangle and the aft triangles. I had seen a design like that over 10 years ago and figured that was the concept here.

So I went ahead and made mine like that. It has two aft triangles and one leading triangle. Turned out great even if not the design intended.