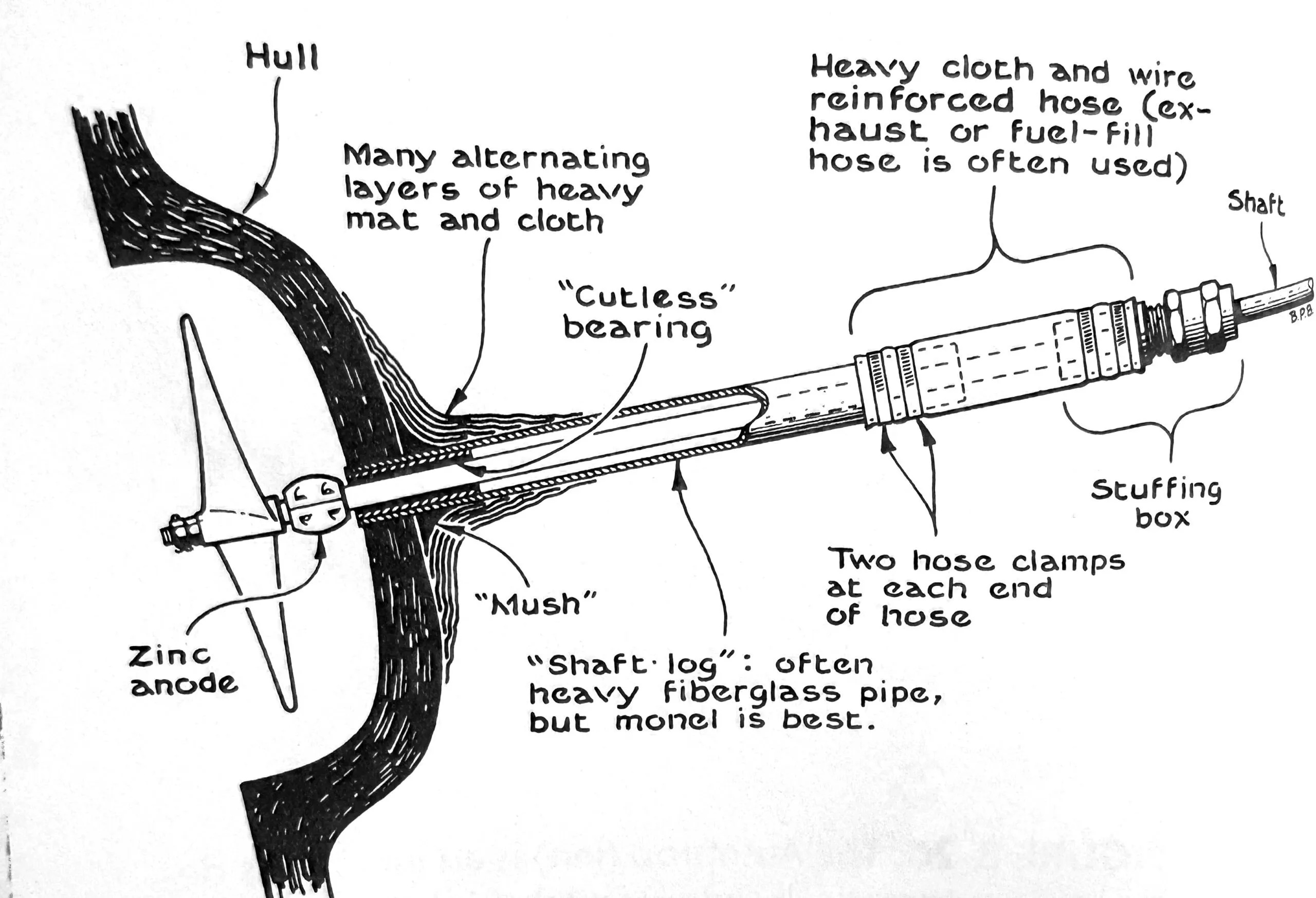

Only boats with inboard engines have stuffing boxes. To locate yours, trace the propeller shaft from the transmission to the point where it exits the hull. That’s where your stuffing box will be, unless you have a newer, dripless-style shaft seal installed instead.

The purpose of a stuffing box is to allow the propeller shaft to exit the hull while keeping water out. The shaft is sealed by compressing packing material against it, most often by using a hollow nut that screws onto a matching fitting attached to the inboard side of the shaft log hose. Another common style features a tightening arrangement that uses a plate secured by nuts and studs on either side of the shaft.

The more you tighten either type of gland, the more the packing gets compressed against the shaft. Most packing consists of a square-plaited material and comes either as traditional greased (or waxed) flax, or a more modern version impregnated with PTFE.

Corrosion and leaks are common problems you’ll encounter when inspecting your stuffing box. The shaft log hose, which connects the stuffing box to the hull in most installations, should also be inspected for deterioration due to age (a common problem), corroded hose clamps, etc.

The Right Number of Drips

Water helps lubricate the packing material so it’s okay for a stuffing box to leak a few drips (3 to 4 per minute) while the vessel is underway. More than that amount (say 10 drops per minute) or drips while the shaft is not turning indicates the need for adjustment and/or maintenance. A leaking stuffing box can cause a number of issues, from corrosion (the spinning shaft slings excess water all over your engine compartment) to sinkings (see “Sinking? Check Your Stuffing Box“), particularly if the boat is left unattended in the water for longer periods of time.

Packing material will harden over time (as the lubricant dries out) and gets worn away by shaft rotation, allowing water to pass and enter the vessel. When this happens, most people simply tighten the packing nut(s) to compress the packing material and stop or reduce the leak.

This works to a point, but as the packing gets smaller it also gets harder. Keep compressing it and it will eventually score the propeller shaft, which will then have to be replaced before the stuffing box will seal properly. Avoid such problems by simply replacing the packing on a regular basis. See “Packing Extraction Tool Tested.”

Dripless Shaft Seals

Dripless shaft seals are an alternative to packing glands. They prevent water from entering the hull via pressure loading, typically by using a compressed rubber bellows to hold a graphite collar against a stainless steel collar. High-speed vessel installations will usually have a water injection hose plumbed to the engine’s raw water cooling systems, which helps reduce heat generated between the two contact surfaces.

While they don’t require re-packing like traditional stuffing boxes, dripless shaft seals still have regularly scheduled maintenance requirements that must be carried out to ensure proper operation. These include periodic removal and inspection, as well as keeping the cooling hose mentioned above clear and open.

Capt. Frank Lanier is an accredited marine surveyor with over 30 years of experience in the marine industry. His website is www.captfklanier.com.

This article was published on 18 January 2019 and has been updated.

Most of our local prop shops and mechanics that do drive train work recomend against the ptfe stuffing. They find that it does last much longer than traditional flax but that it scores the shaft. Rudder stuffing boxes can use the ptfe and gortex stuffing because they do not rotate at high speed.