How big of a backing plate do you need for your new winch? Genoa track? How about for your keel bolts? What is the best material? The best design?

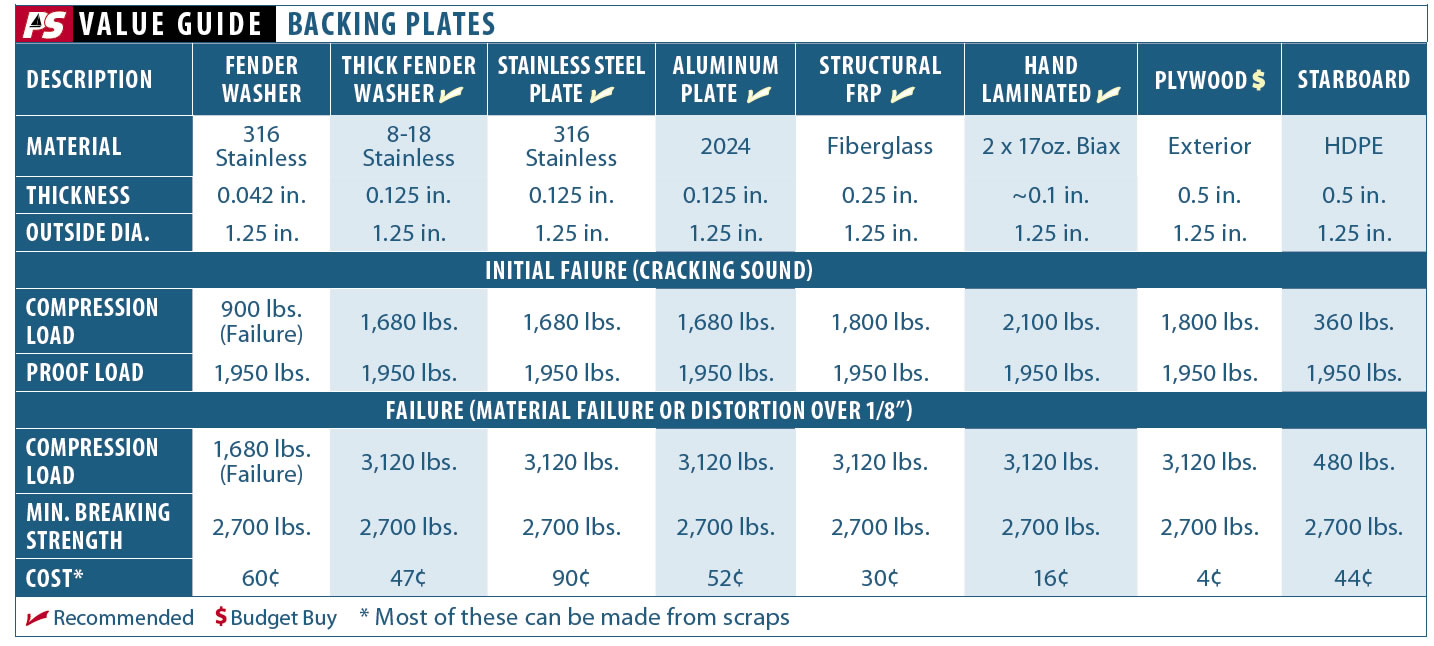

Practical Sailor recently tested the strength of solid laminate with relation to the bolt passing through it (see PS, June 2016 online). We also tested several materials used to make backing plates when attaching fittings, hardware, and structural components to the boat.

Backing plates, often paired with topping plates, play a critical role in spreading load across the substrate to which hardware is bolted. Anyone who has replaced or re-bedded his mainsheet traveler, genoa track, stanchion, winch, or similar deck hardware has probably noticed that the washers used to spread the load on the underside of a balsa-core deck are often bent and mis-shaped, apparently too small to the spread the load.

In this issue, we take our investigation one step further. Now that weve determined that some materials are better than others for backing plates, we sought to find guidance on the minimum dimensions for a backing plate for load-bearing hardware. For this report, we looked at existing practices and compared them with what we found through empirical testing.

What We Tested

Our deck sample for testing was a balsa-cored, half-inch-thick fiberglass that precisely replicated that of PS tester Drew Fryes 32-foot PDQ catamaran. During testing we compared American standard bolting washers and fender washers and several common backing-plate materials, including 1/8-inch aluminum, 3/16-inch and 1/4-inch fiberglass (FRP) plate, 1/8-inch stainless steel, 1/2-inch plywood, 3/4-inch teak, and 1/2-inch Starboard (HDPE). Although some of these materials are clearly a poor choice for backing plates, people still use them, so we included them in testing.

We also made sample backing plates with a few layers of 17-ounce biaxial cloth laminated against the inner skin, and we made samples with FRP plates bonded to the inner skin for increased strength. Our aim was to find materials that can reach the proof strength of the 1/4-inch bolt (1,950 pounds) that we were bolting. We wanted to do this without significant distortion or damage to our sample decks fiberglass skins or its balsa core.

For a plate to meet our criteria, the bolt had to fail before the plate. The data from our tests is summarized in the accompanying tables. For details on the test protocol, see the accompanying How We Tested.

General Observations

It is important to note that our testing looked only at compression and tension. Critical items that exert large sheer forces (forces that are roughly parallel to the substrate that the hardware is bolted to), such as chain plates and mooring cleats, should be installed in thick, solid fiberglass, and the force must be well-distributed to the surrounding structure. A fiberglass-reinforced backing plate bonded to the laminate provides considerable sheer strength; if not bonded, backing plates should be seen primarily as reinforcement against tension or compression-i.e. loads that are in-line with the bolt.

The American National Standard Institute (ANSI) requires washers with a minimum thickness of 0.063 inches for quarter-inch bolting washers, but that is for bolting to rigid, metal surfaces, not for load distribution. It quickly became obvious that standard stainless-steel fender washers bend under heavy loads when used to back anything other than metal.

In our tests, small washers cut through the inner skin of our cored deck sample at about 900 pounds of load, which is about 150 percent of the bolts safe working load of approximately 600 pounds (with a 3:1 safety factor as the bare minimum). Fender washers did not fare much better. They distorted below the working load of the bolt, causing less damage than plain washers to the inner skin, but the overall harm was just as bad. The fender washers became distorted, concentrating loads to the point that gelcoat spider cracking could develop.

Though we based our testing on quarter-inch stainless bolts, this data can be scaled up to larger bolts. The material thickness should maintain roughly the same ratio to bolt diameter (see sidebar), and the overlap should increase proportionately as well. A standard SAE bolting washer is still required with all backing plate materials to provide additional load distribution. Do not use a fender washer or lockwash-only.

The best practice as loads increase is to replace the core with solid laminate tapered into the structure of the deck or hull. For bolts larger than 3/8-inch that are sized to match a load, that load should be distributed at least a few inches with a properly tapered backing plate backed by metal plate or at minimum, a metal plate.

Backing plate materials

Based on our findings, all thick, metal backing plates or washers for solid laminate should be about half the diameter of the bolt in thickness and equal in diameter to five bolt diameters in order to provide sufficient load distribution. All backing plates for cored sections should be at least 10 bolt diameters in diameter. There should be no sharp corners (minimum radius = five bolt diameters). Ideally, the backing plates should be tapered to reduce the stress riser caused by the abrupt transition where the backing plate ends. This is easy to accomplish by shaping or stacking thicker backing materials.

Unless otherwise stated, the thickness for any of the recommended materials discussed below is one-half of the bolt diameter.

316 Stainless Bolting Washer

Surprisingly, the 316 stainless-steel, plain, ANSI bolting washers (0.063 x 0.73 inches for quarter-inch bolt) performed very nearly as well as fender washers. However, they fall well short of meeting high load requirements, cutting through the laminate. We used them with every test material other than stainless plate to prevent the nut from digging into the backing plate material.

Bottom line: ANSI bolting washers are not sufficient on their own.

316 Stainless Fender Washers

The 316-stainless-steel fender washers (0.021 x 1.25 inches for quarter-inch bolts) bent into cones at high loads, the result of being 3 times thinner than standard washers, providing almost no structural support These present a trap for the unwary; they look effective, but do nothing.

Bottom line: A fender washer is no substitute for a proper backing plate.

Aluminum

Most aluminum alloys are easy to fabricate with common tools. Aluminum is lightweight, compact, will bend rather than crack, and is suitable for exposed locations, if its painted or polished. It is vulnerable to corrosion if the bedding leaks, and its not suitable for chronically damp locations. Like all metal backing plates, thicker aluminum plate can create a stress riser where it terminates, thus the importance of tapering and rounded corners.

Bottom line: Corrosion holds aluminum back as an ideal material, though it is suitable in accessible locations where the backing plates can be easily replaced. Ideally, the alloy would be corrosion-resistant marine-grade (5000 series), but its pricey stuff, which is why we search for scrap. Other alloys will work.

316 Stainless Plate

Polished stainless offers great durability, but it is expensive and more difficult to fabricate than the softer aluminum. The higher price can be offset by using scrap pieces. Grade 304 stainless or even painted mild steel (for dry places only) are cheaper alternatives, but since were using scrap, the savings is not a factor.

Bottom line: Recommended if you have the tools to work it.

Precast Fiberglass

Materials such as G10 are corrosion proof, easy to cut and shape, relatively economical, and compact. When superior strength is required, an irregular surface prevents good contact, or there is minor laminate damage, precast fiberglass can be bonded with thickened epoxy, making it a part of the hull. When bonded, 20 to 50 percent less thickness is required, making this particularly useful in tight places.

Bottom line: An excellent backing material, especially when bonded.

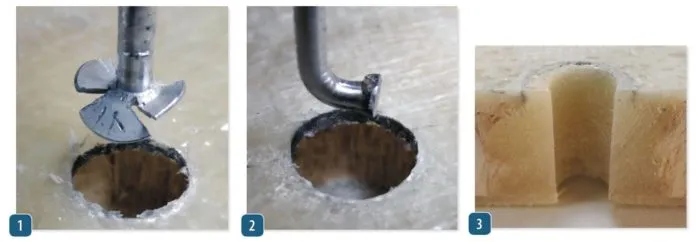

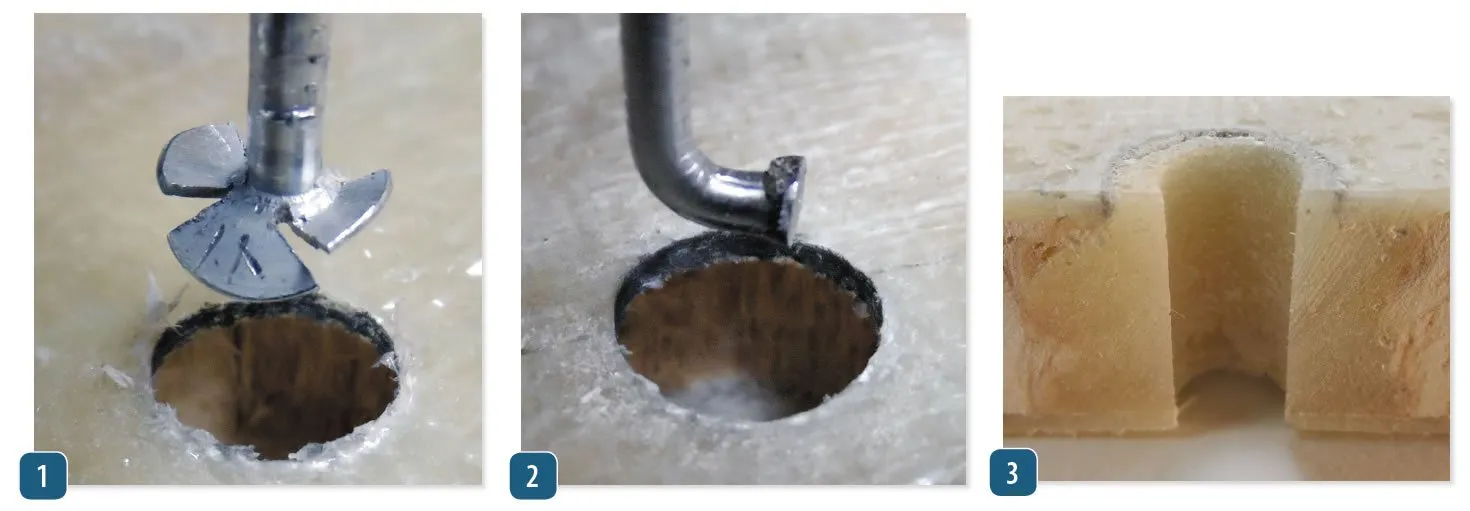

Additional Laminate

Occasionally, a surfaces curvature, irregularities, or proximity to other hardware or deck edges make using a backing plate of sufficient size impractical, or impossible. In these cases, you can add additional laminate-four to six layers of 17-ounce biaxial-to increase strength. Often, this is best accomplished by laying-up and rolling out the laminate on a polyethylene sheet, and then transferring the saturated patch to the prepared area. Tapering the edges of the patch eliminates stress risers and is essential for very light skins. The only real downside, other than added labor and some mess, is that fasteners should not be torqued down for at least one-week, while the patch reaches a full cure; although it may seem cured sooner, it has not reached full stiffness.

Bottom line: This is a great option in tight spots, around curves, and on lightweight hulls.

Teak and oak

Solid wood can make a good backing plate, if its close-grained and at least 3/4-inch thick. Wood is easy to fabricate and cheap. Rot is a problem, so sealing it with epoxy is recommended; however, theres still a risk wood plates will split.

For testing, we used teak and oak (three bolt diameters thick). In our test, the fender washers distorted into cones, which split the solid-wood backing plates. To avoid this, bolts should be placed at least 2 inches from the plate edge. Additionally, metal washers half as thick as a bolts diameter are required to prevent, or at least limit, splitting.

Bottom line: Although some close-grained, water-resistant hardwoods can work, the American Boat and Yacht Council does not recommend solid wood backing plates due to their tendency to split. Epoxy-treated marine grade plywood is a better choice.

Plywood

For our test, the plywood backing plate was two bolt diameters thick. Because splitting is less of a concern, -inch-thick plywood is generally thick enough for quarter-inch bolts. The plywood must be waterproof-glued and epoxy-coated (eating into any time or material savings), and rot remains a concern in the long term. Additionally, metal washers a half-bolt-diameter thick are required to prevent splitting.

Bottom line: Plywood is the Budget Buy pick among strong materials; however, we prefer a rot-proof material.

Threaded Insert Plates

Many builders build thread plates into fiberglass laminate. Threaded insert plates simplify installation and-for a while-re-bedding, but corrosion eventually brings on problems that are difficult to fix.

Bottom line: Not recommended.

Threaded Backing Plates

Threaded backing plates (at least one bolt diameter thick), not built in the laminate, are often bonded in place with adhesive. They simplify re-bedding hardware such as stanchions, particularly on boats that have extensive woodwork preventing easy access to bolts.

Bottom line: A good solution to difficult fitting problems.

Conclusions

Our testing found that a 1-inch washer is too small for a structural backing plate for a quarter-inch bolt in a cored deck. We suggest either a backing plate extending 1 inches beyond each fastener, or a minimum of 3 inches in diameter for high-load applications. These minimum dimensions increase proportionately for larger bolts. Thick metal washers (a half-bolt diameter) must be used with every backing plate material other than stainless steel.

Fender washers are useful when there isn’t enough force to require distribution. But when load distribution was required in our tests, they performed no better than plain washers. HDPE and Starboard have been used as backing plate materials, but they creep, distort, and crack over time, providing no protection against flexing and gelcoat cracking, and little protection against core failure. Dont use these.

PS likes aluminum for lighter-duty applications in dry locations, but its problematic in inaccessible and/or damp locations, where corrosion can be a problem. For high loads-winches and mooring cleats-there is no better backing-plate material than fiberglass, either precast and bonded to the skin, or layers of biaxial cloth laid-up directly when the space is odd or irregular. For very large loads-bolts greater than 3/8-inch-the best answer may be a combination: complete removal of the core, replacement with solid glass, plus a stainless-steel plate. Bonding FRP plate or additional laminate can also stabilize minor cracking resulting from too-thin laminate, avoiding more complex repairs; this is how our test boat was repaired.

In our view, these guidelines can be safely applied to all well-engineered installations, so long as the laminate is consistent with existing building standards and is undamaged. These guidelines should not supersede more stringent installation guidelines from the manufacturer of the product being installed, and we would recommend consulting the boats designer or a naval architect before making significant modifications to structural components such as chainplates.

Many materials are suitable as backing plates. The primary requirements for being a good backing plate material are stiffness and resistance to creep and corrosion. Fiberglass and stainless-steel are consistent winners. Starboard is the big loser for structural applications. Extra thick fender washers are available from fastener suppliers and precast fiberglass from industrial supply houses.