Many years ago, one of our editors had an old wooden boat with lovely wooden handrails just inside the companionway that his sailing partner decided could use new varnish. The original coat, which was peeling around the base and worn where hands had gripped it, was sanded smooth and meticulously coated with varnish. Subsequent coats were applied according to the process that had served well for years-varnish, scuff, wipe, varnish, scuff, wipe . . . repeat.

The handrails looked beautiful, until about a week later when wrinkling, peeling, and lifting was noticed at the base. The problem was blamed on the varnish, a local brand purchased in Cartagena, Colombia, where the boat was at the time. The handrails were left alone until they could track down a more reputable varnish. When it failed the same way, it became obvious that the varnish was not at fault. Only later did they discover that the handrails, installed by a previous owner, had at one point been bedded in silicone caulk. Even with all the sanding and prepping, enough traces remained to interfere with the adhesion of the varnish at the base.

Silicone caulk is notorious for wreaking havoc with the adhesion of sealants and paint. In fact, you will probably find that new silicone bedding does not bond well to surfaces that have been supposedly scrubbed clean. The trouble is that old silicone can be deeply embedded in the pores of gelcoat and wood, invisible to the naked eye.

Instead of silicone, many boaters prefer polyurethane, polysulfide (not compatible with acrylic or Lexan), and butyl caulks because they last longer, leak less, and do not leave behind a residue that will hinder adhesion. But as we saw in our recent report on caulks (see Marine Sealant Adhesion Test, PS December 2016 online), silicone is a versatile sealant and is particularly effective when sealing glazing for portlights and hatches.

The retreat to polyurethane adhesive sealants, such as 3M 5200, raises another bonding issue. They work too good. As we’ve seen in a number of previous tests, 3M 5200-considered by many to be the gold standard for bedding underwater fittings-is not the best choice for fittings that you may want to re-bed.

What many people don’t realize is that 3M 5200 is considered a semi-permanent adhesive-sealant with an emphasis on adhesive. Its grip is so tenacious that it can pull gelcoat right off the deck when hardware is pried loose. It is particularly well suited for through-hulls, but for bedding most deck hardware, there are better solutions. (See The Great Stickup: Practical Sailor Tests Marine Adhesives, Caulks, and Sealants, PS August 2010 online.)

Pondering the adhesive-sealant conundrum, the same questions kept coming back to us. Can we still use silicone products for those jobs that they do best, like sealing plastic and glass glazing, without jeopardizing future repairs? Is there not a solvent that would remove the silicone residue when it came time to varnish or re-bed? And what about removing 5200 or similar high-strength adhesives? Would any solvent that is aggressive enough to soften these caulks also damage the substrate?

What We Tested

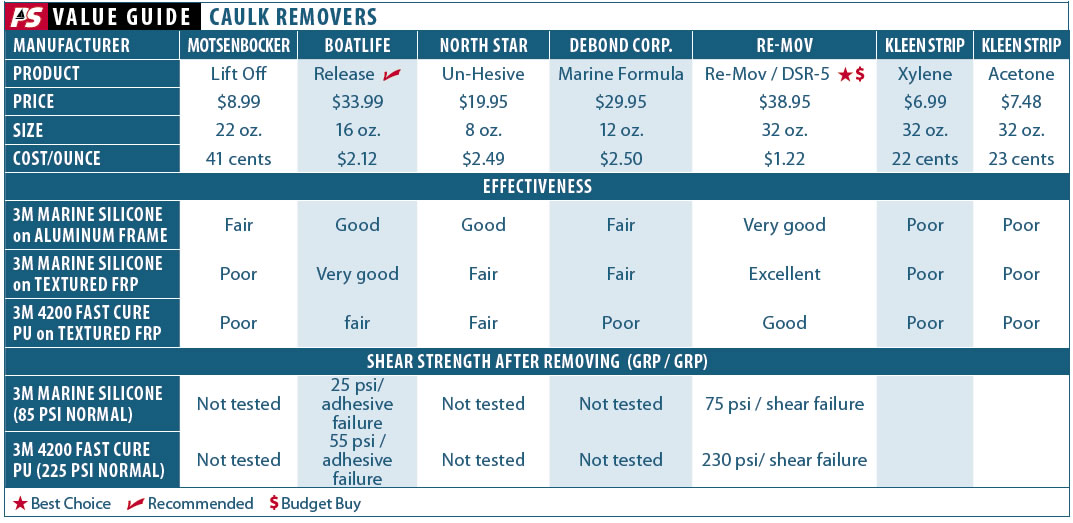

To answer these questions, we mounted a product test of adhesive removers. The test field included the obvious choices, xylene and acetone-solvents commonly used in the marine industry for removing contaminants and prepping surfaces for new paint-from the familiar hardware-store brand Kleen Strip.

The focus of the test field were five products that makers claim will remove any trace of silicone and polyurethane caulks: BoatLife Release, designed to simplify the removal of a wide range of adhesives; Marine Formula DeBond, a patented chemical product to remove polyurethane adhesive-sealants such as 3M 5200; Un-Hesive, another patented product used to remove cured polyurethane adhesive; Re-Mov, a product that claims to break the bond of most commercial adhesives; and Lift-Off Silicone Caulk and Foam Sealant Remover (FSR), from Motsenbocker, a company that offers a wide range of adhesive removers.

None of the products we tested claim to dissolve the caulk, they simply break the bond with the substrate. All suggest that the process may require several applications and a specific dwell time (wait period before scraping or re-application) of up to 30 minutes.

How We Tested

Our first test was simply to compare ease of use, to see how quickly and easily they removed the visible remnants of silicone. For this, we used a hatch that was in need of a lens replacement.

We applied each product to a taped-off section of the hatch and allowed it to soak, according to the instructions. We then followed the makers instructions, following the chemical application with tools designed to help physically break the bond. We used tools that have served well on similar projects, a razor knife, a wire brush, and a hose hook, which resembles a bent ice pick. (See Hose Fitting Tips, PS May 2016 online.) After comparing the performance on the six taped-off sections, we used the most effective product to clean the entire frame and set it aside for reglazing. The reglazed hatch will be incorporated into a long-term test against untreated controls to determine whether acrylic/aluminum adhesion is in any way compromised or improved over time.

To test the removers debonding effectiveness on gelcoated surfaces (as well as any potential harm to gelcoat), we covered six gelcoated, 1/8-inch-thick fiberglass coupons with a thin layer of 3M Marine Silicone Caulk. Six other identical coupons were coated with 3M 4200 Fast Cure polyurethane caulk. Testers let the bonded coupons cure for six weeks, then treated each coupon with an adhesive remover, making three applications 30 minutes apart. We examined the samples after each application, gently testing adhesion.

After the final application of each product, we began scraping one side of each coupon with a plastic scraper to compare ease of removal. If we were able to remove most of the caulk from a coupon, we cleaned more aggressively using a wire brush by hand. We then added a second application of the same caulk remover, and finally, we cleaned the coupon with soap and water. Any coupon that came reasonably clean was then bonded to an identical, untreated coupon using either 3M Marine Silicone or 3M 4200.

Observations

Neither acetone nor xylene had any measurable effect on either silicone or polyurethane, so that is all well say about them here. On the aluminum hatch frame, all five of the dedicated caulk removers significantly weakened the bond of the silicone caulk and helped reduce prep time, but Re-Mov performed the best. We used Re-Mov to do the final cleaning on our aluminum hatch frame and were impressed with the result.

On the fiberglass/gelcoat coupons, BoatLife Release, DeBond, and Re-Mov softened the silicone and loosened the edges after the initial treatment and scraping. However, when we began scraping the coupons with a soft plastic scraper after the second treatment, the Re-Mov sample was clean after just a few strokes, with only traces of silicone remaining. A third application of Re-Mov and a little scrubbing with a regular toothbrush removed 100 percent of the remaining caulk.

BoatLife Release made it much easier to scrape away the silicone caulk, but considerable residue was left in the depressions. Even after retreatment with BoatLife Release and vigorous scrubbing, it was clear that only aggressive and potentially damaging methods such as a wire brush or grinding would remove the rest of the silicone. In the end, only the Re-Mov and BoatLife Release coupons advanced to the bonding test.

Although vendors claimed their products were highly effective on polyurethanes, our experience didn’t match the claims. After the first application to the fiberglass coupons, we saw little change in adhesion. However, after repeated applications 15 to 30 minutes apart, we met success. With the aid of a razor knife and some hand scrubbing with a wire brush, Re-Mov and BoatLife Release were able to get down to a bare surface with minimal gelcoat damage. Of the two, the BoatLife Release was the most effective on polyurethane.

We also tried using the test products to release the bond between of two of our sample gelcoat/ fiberglass coupons bonded with high-strength polyurethanes. No matter which product we used, the samples simply could not be separated without breaking the relatively fragile coupons.

After test-followup conversations with some adhesive-remover makers, weve decided to re-test all of the products on fiberglass-to-fiberglass bonds made with 3Ms 5200. Look for an update on these results in an upcoming issue.

All of the products were more effective at breaking the bond between polyurethane adhesive and aluminum. Two polyurethane adhesives, 3M 5200 and 3M 4200, could be released from aluminum using any of the removers. However, none of the products could break the bond between aluminum and Loctite PL S40 or Loctite Marine Caulk.

Our final test proved that at least one product could remove silicone without compromising subsequent adhesion. The fiberglass/gelcoat coupons that had been treated with Re-Mov and BoatLife Release were thoroughly scrubbed and washed with soap and water and then bonded to identical, untreated textured gelcoat/fiberglass coupons. The samples were allowed cure for eight weeks and then pulled to failure. The BoatLife Release yielded results that fell short of the bond strength between untreated surfaces, but Re-Mov impressed us by restoring full bond strength to the silicone-contaminated surface.

BoatLife Release

This product comes in a convenient spray bottle and is advertised for its ability to remove cured sealants from fiberglass, wood, metal, and glass. It also is supposed to work on residue from decals, tapes, labels, and other adhesives, and is safe to use on most carpeted, vinyl, plastic, and painted surfaces. When attacking the aluminum hatch and the textured fiberglass samples, BoatLife Release quickly softened the caulk, and some of it began peeling. But after three applications, 15 minutes apart, it was clear that it wasnt releasing the bond completely, and that aggressive cleaning with a wire brush would be needed. It was moderately effective on polyurethane.

Bottom line: BoatLife Release is recommended for tough jobs involving polyurethane. It finished in second place for overall performance.

Motsenbocker Lift-Off

Motsenbackers Lift-Off Silicone Caulk and Foam Spray Remover comes in a spray bottle, but it is a gelled liquid that must be spread around with a brush or plastic spreader. It was more effective than xylene and acetone when cleaning the aluminum hatch frame, but was completely ineffective on textured fiberglass.

Bottom line: Lift-Off does not compare well to other products in this category.

Re-Mov Silicone and Adhesive Remover

This remover was our most effective overall for removing both silicone caulk residue and polyurethane adhesive. According to the maker, Re-Mov will debond polyurethane-bedded hardware even if it has been in place for years. While we found it a bit slower acting than other products, the end results were truly impressive. Two applications, 15 minutes apart, a few quick passes with a plastic scraper, 20 seconds scrubbing with a bristle brush, and a good wash with soap and water, eliminated all the silicone from a textured deck, allowing it to match original bond strength.

If we had a bonding or coating job in which silicone contamination of the surface was suspected, this would be our antidote. Polyurethane caulk was a tougher challenge, but it did allow us to remove the caulk without damaging the gelcoat.

Bottom line: Re-Mov is the PS Best Choice and Budget Buy for removing silicone or polyurethane caulk.

Un-Hesive

Un-Hesive is advertised to be specifically formulated to release the bond of extremely potent polyurethane adhesive sealants such as 3M 5200 and Sikaflex. Makers claim it breaks the grip of these polyurethane adhesives without material breakdown. It is meant to be sprayed on, and the cured sealant is to be easily peeled off. Our own experience fell short of expectations.

Bottom line: Un-Hesive made it easier to clean the aluminum hatch, but its poor performance on textured fiberglass dulled our enthusiasm. It was not effective on polyurethane caulk.

DeBond

The lone aerosol in the group, Marine Formula DeBond is the signature product of DeBond Corp., one of the first companies to put these types of products into the hands of do-it-yourselfers. DeBonds claims specifically targeted 3M 5200. In our tests, it helped a little when dealing with silicone caulk, but it was not very effective on polyurethane.

Bottom line: Were withholding a final rating on DeBond pending the results of our 5200/fiberglass re-test.

Conclusion

Based on our experience with a couple of these products, we see no good reason to ban silicone from the boat, or to rev up the grinder every time you pull up a 5200-bedded stanchion. Re-Mov is the clear winner in the silicone-caulk removal category, but youll need a little patience. Wait 15 to 25 minutes before attacking the adhesive with a scraper. If polyurethanes are the bane of your current project, reach for the BoatLife Release, but expect that it is still going to be hard work, with considerable scraping and other mechanical efforts to remove the final traces.