Ideal Drogue setup will require experiments

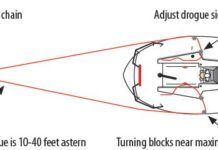

For maximum maneuverability, the control lines-one port, one starboard-should attach at the widest part of the boat. This maximizes leverage and places the effort close to the center pivot point. On a catamaran, closer to the transom works because of the wide beam, but for monohulls, attaching near the pivot point at the keel will be more responsive. For maximum responsiveness, the drogue should be as close to the transom as practical-this results in more responsive steering and minimal drag. We found the best compromise to be around 65-80 percent of the way aft, where there is still enough beam, but less risk of the control lines fouling.

Product Update: Facnor FX+ Furler, Caframo Scirocco II, and More!

With lighter summer breezes soon upon us, a retrofit to a furling light-air asymmetrical sail grows tempting. Facnor, maker of one of our top-rated gennaker furlers in 2009 and 2011 (Foil-less Furler Test, PS April 2011 online) has introduced its new FX+ range of high performance continuous line furlers for free-flying sails. The new furlers incorporate a lightweight carbon fiber drum housing, exclusive quick release attachment system for easy use, and a new ratchet type lock, which prevents the drum from unwinding while the sail is furled.Designed to be highly adaptable, the FX+ range works well with almost any free flying sailing sail-ranging from a Code Zero, staysail or storm jib. They can all be quickly converted to a top-down style furler using Facnors optional Fast Swivel system. Facnors push-spring release system allows for simple snap-on attachment, as well as one-handed removal activation. The FX+ range includes sizes and models to fit boats from 21 to 70 feet.

The One-Bucket Cleaning Kit

Bright, shiny and new looking. That was what we wanted when were shopping for our dream boat, and that is the impression our new-used PDQ catamaran gave. What was behind that spit-shine on a used boat? Besides the obvious hours of labor by the previous owner, it took two baskets of cleaning products, all stuffed in the stern lockers.

A Generic Approach to Specific Stains

For general deck cleaning, unless there is a specific stain, always start with a relatively mild, biodegradeable surfactant. Not strong enough to remove wax or corrode metal, but enough to loosen what the birds left, hard water spots, and atmospheric dirt. One possible remedy is a little spot cleaning with biodegradable laundry detergent. Today, most detergents are biodegradable.

Boat Spring Cleaning

We frequently receive suggestions for new cleaners from our readers. Here are a few suggested products that came over the transom that we havent reported on before.

Mailport: Whats Up with Synthetic Lifelines?

Its been almost five years since your original article on synthetic lifelines (Long-term test Evaluates Synthetic Lifelines, Practical Sailor, September 2012). Since my coated lifelines are due for replacement, Im curious about long-term observations. That said, I plan on going up a size or two from the recommended numbers for an extra safety margin: 6 millimeters rather than 5 millimeters. Im still looking into manufacturers and products because I just learned how easy splicing 12-strand can be, but Im pretty sure almost any of them will be better than the plastic-covered stainless-steel wire, of unknown vintage, thats on the boat now.

Marine Weather Forecasting

Over the last few decades, theres been exponential growth in the availability of accurate weather forecasts and the net result is safer voyaging. Government spending on weather data gathering and forecast development has soared. Satellites and data buoys have filled in some of the oceanic gaps caused by an absence of weather balloon sampling at sea. State of the art, algorithm-driven, model data and ensemble-based forecasting have turned electronic guesswork into a better understanding of atmospheric volatility. The net result is an increase in the validity and reliability of marine forecasts and a trend that has stretched 24-hour forecast accuracy into 48- and 96-hour time frames. So, if anything deserves the label don't leave homeport without it, it is todays, better than ever, marine weather forecast.

Fuel Level Sensor/Return Line Durability

I have a 2008 Gemini 105MC catamaran that I purchased new, and the fuel tank level indicators on both tanks failed a couple years ago. However, I noticed that the fuel-return line is attached to the top of the fuel level sensor. It seems to me that this may be the problem-fuel spraying down on the level indicator shortens its useful life. All the other Gemini owners that I know also have had the level indicators fail. It is not a huge problem. My tanks are transparent so I can see the fuel level in the tanks. My friends who have black non-transparent tanks use a wooden stick-which can be inserted down the fill hose.

Testing for a Life at Sea

Without the keen eye of experts who know what to look for, product testing can offer only a partial picture. The insight gained through hard won experience becomes more valuable at sea, which is why this months issue focusing on offshore sailing turns to four noted experts for advice on topics ranging from gear selection, to weather forecasting, to boat maintenance.

Best Boat Bottom Paint 2017

The list of contradictions that define our sailing affliction is long. We need an anchor that buries deep but can be freed at a moments notice. We want a sealant that sticks to anything, but releases its grip for easy disassembly. We want a boat that can weather any storm, and still make way under sail in a whisper. And we want an antifouling paint that repels every sea creature, but will never harm the sea.