This month’s discussion of random orbit sanders revived fresh memories of last winter’s arduous project removing six layers of paint from the deck of Opal, the 1971 Yankee sloop I’m restoring. Although many of us have been using power sanders for years, it’s worth going over some of the basics on use and care.

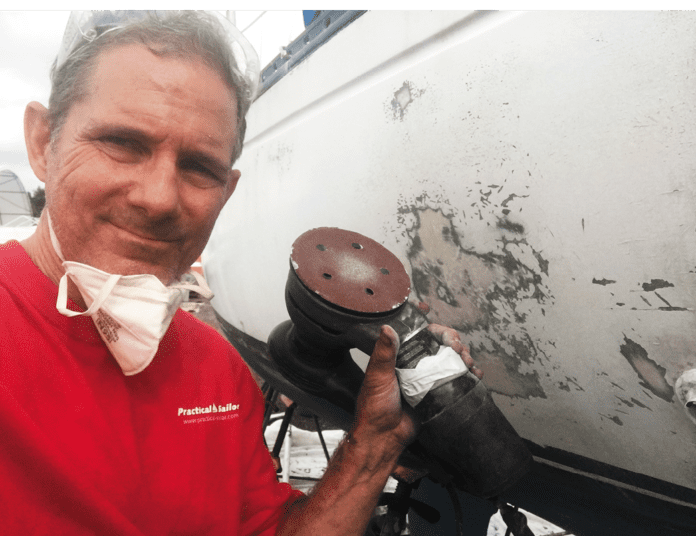

Safety. For any sanding project, even outside, I wear a close-fitting P-95 mask approved by the National Institute for Occupational Safety and Health (NIOSH). For long projects, sanding bottom paint, or working in well-ventilated indoor spaces, I prefer wearing my respirator with NIOSH P-100 filter (see “Best Respirators for the Boatyard,” PS September 2017).

Although not as dangerous as grinders, sanders can whip loose paint and dirt into your eye, so wear safety glasses or goggles. Ever since a good friend nearly lost his eye while using a wire brush, I habitually put on safety glasses before I plug in any power tool.

Technique. Heat is your enemy. The aim is to maximize the cutting ability of the abrasive paper without heating up the surface. Heat burns through layers you don’t want to remove, and clogs your sandpaper more quickly.

Keep the tool flat against the surface you’re working on and apply even, firm pressure. Don’t tilt the tool at an angle or bear down on it. Keep the sander moving and let gravity do the work. The sander should smoothly glide across the surface.

Today’s sanders won’t spin if there is no pressure on the sanding pad, but if you have an older tool, this can still happen. To prevent swirl marks, start with the tool firmly in your hand, while it is on the surface you are sanding. Lift the tool clear before turning it off.

Sandpaper. For my paint removal project, I settled on Mirka Abranet, a screen-like disk embedded with long-lasting ceramic abrasives. Frye favors Diablo SandNet, a very similar product. In addition to the net-style abrasives, I tried several conventional sandpapers from Gator (aluminum oxide/zirconium), Diablo (ceramic blend), and 3M (Cubitron II Xtract ceramic blend). I found these abrasives effectively cut through wood stock, but the screens lasted longer and clogged less when removing paint and fairing fiberglass. When the screens clogged, a pass with a vacuum cleaner quickly revived them.

Cleaning. An easy way to ruin your new random orbit sander is to put it away dirty after each use. Most yards have an air compressor handy to blow the dust out of your tools. If you have a shop vac or cordless vacuum you can find a micro-adapter kit or crevice cleaner to blow the tool out as well.

With the right use and care, your random orbit sander might very well outlast your boat. My own RO sander, a Porter Cable 343 (recently updated with new bearings) is still going strong at 14 years.