The hallmark of an overboard fall protection system is a system of jacklines running along the deck, with tethers attached so that the sailor can move throughout the boat with relative freedom. But this is not the real backbone of the system. A review of overboard accidents reveals that very few fall when transiting from cockpit to bow—they get washed overboard when they stop to perform a task. While moving, sailors are focused, holding on with two hands, and mindful of the approach of waves and the motion of the boat. But while taming a headsail or straightening up a tangle of line in the cockpit, the mind wanders, the hands are occupied, and risk increases. A wave strikes, we tangle our feet or step on a sail, and whoosh—we’re overboard.

We’re no longer tying the helmsperson to the wheel, but the principle is the same. Today’s ocean racers use workstation tethers that are already attached at grinding stations and the mast. These tethers are typically 2- to 4-foot lengths of line with a quick locking connector. The sailor doesn’t have to use his personal tether everywhere.

Having pre-installed tethers at specific work stations can help prevent a tangled mess in small, sometimes crowded areas like the cockpit when things are moving fast. Jacklines are effective for moving about, but the fixed clip-in points are the first line of defense at the dedicated work stations where sailors are most vulnerable. In this report we will explore hard points and tethers as an invaluable supplement to jacklines. Even while your 2-meter tether remains hooked to the jackline, real security comes from clipping the 1-meter leg to something fixed.

4.04 Jackstays and Clipping Points 4.04.1 Permanently Installed fittings for jackstay ends and clipping points. 4.04.2 Jackstays which shall: a) be independent on each side of the deck, b) enable a crewmember to move readily between the working areas on deck and the cockpit(s) with the minimum of clipping and unclipping operations, c) have a breaking strength of 2040 kg (4500#) and be uncoated and non-sleeved stainless steel 1 x 19 wire of minimum diameter 5 mm (3/16”), webbing or HMPE rope. 4.04.3 Clipping points which shall: a) be adjacent to stations such as the helm, sheet winches and masts, where crewmembers work, b) enable a crewmember to clip on before coming on deck and unclip after going below, c) enable two-thirds of the crew to be simultaneously clipped on without depending on jackstays, d) on a trimaran with a rudder on the outrigger, permit a crewmember to repair the steering mechanism whilst attached to a clipping point.

Jackline Details

Length of Jackline

the development of snap-hooks that,

unlike the one pictured above, resisted

accidental release. Some of the measures

taken to prevent this are proving less effec-

tive than previously thought. (Photo/ Drew Frye)

The rule does not require that jacklines run from bow to stern or that they are continuous. They can stop some distance from the ends, since you can stand tall at the bow with the 2-meter tether attached fully 4 feet behind you. When the 2-meter tether slides to the end of a bow jackline, it hangs uselessly slack. Protection near the extreme ends is supplemented by clipping the short tether to hard points. Jacklines may also be broken into sections, helpful for working around obstructions, keeping them a little farther inboard, and reducing lateral deflection due to stretch.

Multiple Clip-In Points

Because the requirement to hook on two-thirds of the crew without relying on the jackline would require a lot of padeyes, race inspectors have told us that short secondary jacklines in the cockpit area, for example, can fulfill part of this requirement. But hard points and workstation tethers are also needed.

Impact

With the current crop of low-stretch tethers and Dyneema work station tethers, any fall against a hard point will be as jarring as hitting concrete. In at least two incidents of tether failure, the victim was clipped into a hard point.

Glyn Charles was clipped into a hard point in the cockpit when it broke during a rollover in the 1998 Sydney-Hobart Race. Richard Sharp’s harness broke in a knockdown during 1983 Pacific crossing—clipped to hard point in cockpit.

In jackline falls, the stretch of the jackline is sufficient to limit the arresting force to about 500 pounds. In a fall against a fixed point, using a tether with limited stretch, the force potential is boundless. For commercial tethers, the ISO standard does not specify a maximum impact force, as do climbing and industrial standards.

The situation is even worse with Dyneema work station tethers because there is no impact absorption, other than the rotation of your body and the bending of your ribs. For more discussion, see “Building a Custom Safety Tether.” Do everything possible to limit the amount of slack in the system, because the sudden stop is dangerous and will hurt.

Fixed Point Details

Strength

Curiously, the World Sailing Off-Shore Rule and ISO do not specify hard point strength. Common sense dictates matching the breaking strength of tether components (20 KN or 4,500 pounds). If only the safe working load is given, the breaking strength is typically at least two times that figure (practices vary). In some scenarios it can be prudent to clip the secondary tether into a pulpit or other non-standard hard point as long as the sailor is also clipped into a jackline or dedicated hard point.

Extensions

Eccentric, cross loading has been cited as a cause for failure in the recent Clipper accident. One way to prevent this is to a short Dyneema loop extension to the fixed clip-in point, or to use dedicated a work station tether that is always in place. Extensions are also useful for U-bolts that must be shared with other rigging. A sailor can also carry a short sling on his harness in case he needs a hard point where one is not rigged. Inspect for sharp edges before attaching a fiber sling.

Work Station Tethers

The tradition of lashing the helmsperson to the wheel goes back to the beginnings of sailing. Work station tethers pre-installed at vital points make sense. The length can fit the task perfectly, they reduce potential for tether tangles, and they avoid cross loading problems at the attachment point. Often they can simply be spliced or tied around something strong, like the base of a steering pedestal or to the mast and equipped with a safety snap.

Tether Material

Amsteel is popular because it is very compact, splices easily, and resists UV. However, because of its complete lack of stretch it is not permitted in climbing or industry for tether use. It is unforgiving and the impact is jarring even during falls as short as 1-foot. Nylon webbing or rope, though not as durable in the sun, provide safer retention. Although impact is a minor consideration for short tethers around the mast or stays, it can be vital for the helmsperson; two of the losses quoted above were helmsmen. More elastic climbing rope is ideal and is commonly used in industry for lanyards.

Tether Length

The tether for fixed point use should be no longer than required for the job. Ideally, it should not exceed 1 meter. It should be oriented such that there is very little slack when in use. Because waves generally come from the front quarter, attachment in front of the work station is most common, but it should prevent the most dangerous fall direction, which may be forward or athwartship.

Be Wary of Weak Structures

For example, many steering pedestals cannot withstand a hard hit up high without damage, which can leave you with no steering. Attach the tether to the base, preferably secured to an independent anchor.

Self-Locking

The carabiner must be self-locking. Screw gate carabiners serve well on attachments that are infrequently changed.

Loops in the Jackline

Some large race boats have taken to splicing loops into Amsteel jacklines at workstations. They are smooth enough that a carabiner will slide right over them, while allowing a sailor to work at a station without the risk of being washed the length of the deck. However, underlying jackline standards are based on the worse case fall of a single sailor and the assumption that no more than two people will be on a jackline at one time. If your plan may result in more than two sailors on the line, go up in size 50 percent for each additional sailor. There has never been a documented case of a jackline failing, but this is a risk on larger boats with larger crews.

Shorten Your Tether

If the tether is too long to give good safety—even the short leg—it can be shortened by doubling it around the jackline or hard point.

Location

Hard points should be located to protect all relatively common tasks. At a minimum, they should be one on each side of the bow, near the mast and near the inner forestay, several surrounding the cockpit, and near all frequently used work stations.

Clearance

Do not locate the fixed clip-in point within 2 inches of anything that could cause cross loading, gate impingement, or with a sharp edge.

Avoid the Bow or Stern

Fixed clip in points should be at least two feet away from these areas. Specific to the bow, a sailor can be thrown forward when the boat stuffs a wave. On multihulls, this spacing should be greater and is relative to the front crossbeam in the forestay area. Multihulls may require additional hard points near the bows and transoms, depending on the need to access those locations.

Toerails

Aluminum toe-rails, because they are so close to the side, are less than ideal clip in points. Because they are at the edge of the deck, they should be used only for positioning or bracing, the other tether should be on the jackline or inboard hard point, and they are most effective when you are sitting. If used, they must be through-bolted and not attached with self-tapping screws. They are also to cross gate loading; the holes must be large enough to allow the carabiner to rotate, and they should be clipped from underneath, with the spine towards the deck.

• UV Damage. A requirement for a flag that faded in a predictable manner would be nice. About one year of full-time exposure to the sun is known to weaken webbing about 25%, a fair basis for retirement. • Abrasion. With machine stitching, any appreciable general abrasion, wear around carabiners, or broken stitches at the ends of the splice are cause for retirement. Scratched carabiners, on the other hand, are usually fine, although any cracks or other signs of crevice corrosion in the hardware is cause for concern. • Corrosion. Any stiffness in the gate can prevent proper closing. A brief soak (1-3 hours) in vinegar or diluted CLR (better) may free up stiffness due to superficial corrosion or lime deposits. Lubricate with waterproof grease or spray corrosion inhibitor and place them back in service. If longer soaking is required, retire it. Corrosion in key structural areas of the carabiner are also important; any corrosion or separation of the anodized coating in the nose area or around any of the gate pins is grounds for retirement. • Overload flag. Obviously, a tether should be retired when its overload flag has been exposed, even partially. But you don’t throw have to throw them away. The old tethers are still good for a variety of uses. Cut the slings off and put them to use in less critical areas like securing fishing rods while trolling, or as deluxe dinghy or kayak painters. The webbing can turn into reefing and sails ties, or sewn into any number of interesting projects. Waste not.

during testing in 2007. It is no longer used in sailing tethers. (Photo/ Drew Frye)

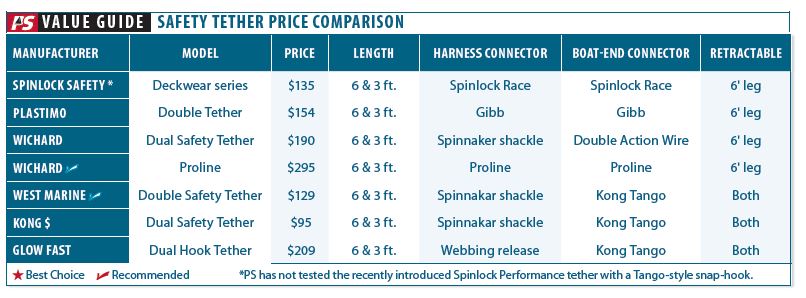

Accidental Unclipping

Most safety clips are vulnerable to unhooking if twisted or pushed in the wrong direction. All clips are weaker in this direction, and every effort should be made to clip from inside the U-bolt (spine toward the deck) so that the gate is not pressed against any solid object.

- The Wichard Proline can be unlatched if dragged between two objects backwards.

- The Kong Tango can be kicked off if the gate is pressed against something.

- The gate of Spinlock and Plastimo hooks can be forced open with a 30-pound pull.

- The ISC SH 903 require three separate actions. We couldn’t figure out a way to trick it off.

Screw locking carabiners require a separate action to lock, but may offer the ultimate in security.

Cross Loading

The 2017 Clipper accident involving the loss of Simon Speirs is presumed to have resulted from a carabiner becoming trapped under a deck cleat and then loaded sideways. While stronger carabiners are available, bad loading is always forbidden by the manufacturer for good reason; such practices weaken the carabiner many times, are difficult to predict, and can damage the gate over time.

With the exceptions of the ISC SH 903 and screw-locking carabiners, we were able to devise a combination of twists and bumps that would dislodge every carabiner with less than 30 pounds force. To some extent, the user can prevent these problems by attaching the carabiner in the optimum orientation. But we must strive to create hard points that are mistake proof.

When testing the security of an attachment point remember that no cross loading or gate impingement should be possible though range of rotation. Be sure to test the full arc that the carabiner can move through and every way the sailor is likely to clip it.

In some cases, clip orientation can improve security. For example, U-bolts should be clipped with spine against the deck and aluminum toerails should be clipped from underneath.

U-bolts and Padeye Openings

These should be round and allow carabiners to easily flip and rotate. For UIAA type K climbing carabiners and similar designs, the opening needs to be at least 15/16-inch wide and -inch tall. Rectangular padeyes should be avoided because they restrict smooth rotation. Many folding padeyes, though strong enough, are too small.

Folding Padeyes Should Be Reserved for the Cockpit Floor or Seats

They are strongest when the load is perpendicular to the hinge and they are partially folded away from the side with two fasteners (this is the opposite direction from fixed padeyes and U-bolts, which are stronger when the force is aligned with the U). All other locations should use fixed hard points to facilitate one-handed clipping.

Bolt Hangers

Bolt hangers can create strong anchor points where a 3/8-inch bolt is already available. See “Ocean Tested: Rock-climbing Gear.”

Sole Use

You should not clip into U-bolts and other hard points used for other rigging if this creates a cross load or could impinge upon the upon the gate—as it usually does. Instead, attach a small loop of line (5 mm Dyneema spliced into a loop) or a pre-fabricated Dyneema rock climbing sling. Do not use nylon-the UV resistance is inferior. A U-bolt cannot be shared by two sailors if crossing is possible.

Stanchions

These will not meet the 4,500-pound standard if clipped above the base. However, an extension sling threaded inside the base can make for a strong anchor. The base must be through bolted with backing plates (no self-tapping screws). The combined strength of the fasteners must exceed 4,500 pounds.

Railings and Handrails

Like stanchions, these are not strong enough to meet the 4,500 pound standard without serious deformation. That said, it can be a prudent to clip the pulpit for bracing with a short tether, so long as you are also secured using a 2-meter tether to a jackline or strong hard point.

Trampoline Lacing

This might be used as a stabilizing hard point if the lacing is 7 mm polyester minimum (5 mm Dyneema) and it is laced to eliminate a zipper failure (the lacing must be tied with individual loops or locked off every few feet). Do not clip a bight of lacing, since the failure of a single grommet will release the clip.

Identification

It may be beneficial to identify designated hard points with conspicuous paint or reflective tape. This prevents use for other rigging purposes and alerts new crew.

No Sharing

Unless a hard point is equipped with a sling extension or work station tether, it should not be used for any other purpose. Two sailors should not clip to the same point, unless one is via an extension sling (very handy around the cockpit).

Mast Loop

A hard point can be made with a strong loop at gooseneck height. This gives better support than an anchor down at your feet. Watch out for sharp edges.

Inspect the jackline path for snag hazards. Because jacklines sag under load, these may be some distance to leeward.

Conclusions

An MOB prevention system is only as good as its weakest link. Each hard point must receive the same amount of attention as a car seatbelt anchor. Like jacklines, hard points should not be a casual afterthought if we expect it to work properly.

Yes, a strong clip-in point involves work. You need to drill holes and install backing plates See “How Big Do Backing Plates Need to Be.” You’ll need to throw out old thinking and look at some new concepts, using new skills and techniques. Fortunately for the rest of us, ocean racers driving high speed boats have developed a wealth of knowledge we can tap.

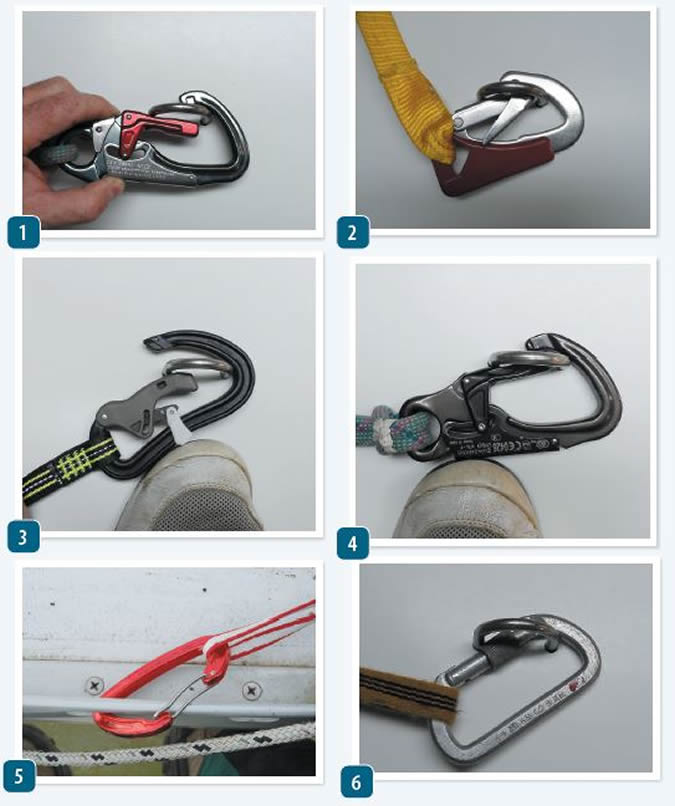

After studying fixed clip-in points on a variety of boats, PS tester Drew Frye took his observations into the lab. Nearly every design had an Achilles heel, some more concerning than others.

1.The ISC CH 109 climbing tether hook requires three actions to release. This is inconvenient, especially when wearing gloves, but accidental release is seemingly impossible.

2. The Gibb-style hook opened under loads of less than 30 pounds in this orientation.

3. The Wichard Proline hook could be coaxed open with an ill-placed foot.

4. The Kong tether was also vulnerable to getting squeezed open.

5. Toerails are poor choice for clipping in, but if they are used, the gate should be up. This clip can self-release.

6. Screw-lock carabiners did not accidentally release, but it requires some attention to ensure it locks properly.

This article was published on 14 March 2018 and has been updated.