You don’t have to look far to find a case in point supporting our recent Practical Sailor Special Report on high-tech lines, which emphasized the importance of paying attention to detail when working with ropes made of ultra-high molecular weight polyethylene (UMWPE) fiber.

On September 4, 2015, Andrew Ashman was killed during an accidental jibe, when the boom delivered a fatal injury to the base of his neck. The boat, CV21 Ichor Coal, had been running in strong conditions, and yawing allowed the wind to get on the wrong side of the mainsail, as occasionally happens. A preventer was rigged, but a strop securing a low friction ring turning block near the bow failed, allowing the boom to cross the cockpit unrestrained. On such highly engineered boats, how did this happen?

According to the report published by Great Britains Marine Accident Investigation Board, the failure was traced to a poor choice of splice. Also sometimes referred to as High Modulous Polyetheylene (HMPE) ropes, UHMWPE products like the Marlow D2 Racing Rope used on the Clipper boat or a similar products (Samson’s Amsteel, NE Ropes’ Endura), must be spliced using product specific procedures. All common sailing knots will slip at a small percentage of breaking strength unless modified, and even then, the low stretch nature of HMPE makes them low strength (poor load sharing).

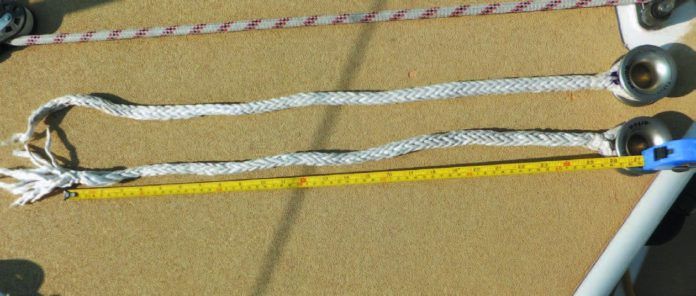

The standard method for forming eyes in hollow braid ropes, like that in question, is a long bury splice, where the tail is about 72 line diameters long. Like a paper finger trap, the harder the rope pulls, the more the herring bone weave contracts on the buried tail.

To prevent the long bury splice from loosening as the rope flops around unloaded, the tail is locked in place at the base of the eye with either lock stitching or a Brummel lock. Neither adds much strength to the splice, and both are intended only to stabilize the splice when unloaded, something all splices can benefit from.

Because there was not enough space for a long bury on each tail, the rigger apparently relied on the Brummel lock alone to carry the load.

This decision was based on the misconception that a Brummel lock actually locks the lines together and can carry safely load. In actual fact, a single Brummel (two passes), such as used on Ichor Coal, can hold only 40-60 percent of breaking strength before failing, which it did.

A better construction, when space is limited, is two separate spliced loops, as used on manufactured products such as Harken LOOPS or pre-spliced low friction rings from Antal, Nautos, and others.