SALUTE TO CHARLEY MORGAN

Regarding your memorial to Charley Morgan and his enduring boat designs (see “Eight Bells for Charley Morgan,” PS February 2023), your praise for the Morgan 41 was spot on. In 2017 we were getting ready for retirement and thinking about a post-retirement boat. After much thought and researching newer boats we were unable to find a boat that fit our needs better than our Morgan 41, Shadow, so we made the decision to undergo a five-year refit to spread the cost and make her “as new” and set up for the next 20 years (we retired in 2020). The refit included a repower, new electronics, new sails, complete deck upgrade (including ports, paint, Flexiteek synthetic decks, new teak toerail—a huge project—and new Edson steering. This year is the final piece, we will add an anchor windlass (Maxwell vertical) and undergo a below-deck upgrade which, as you know, is mostly old faded Formica. We hope to reface all bulkheads with wood veneer, add refrigeration and some cabinets and be done. This is the final piece. It has been an interesting journey for sure, especially with COVID-19 right in the middle of our plans. But for us its been well worth it.

Charlie Margeson

Shadow, Morgan 41

Amityville, NY

TRAPPED IN A LOCKER

The report on locker safety (see “Staying Safe in Confined Spaces,” PS March 2023), made me think about, as author Drew Frye put it, ‘a potentially harmful position’ I was in several years ago. That early warm spring day had me making some cable adjustments while prone in a large cockpit locker on my former Cal 35 (Caliente) on the hard. While thinking I was grabbing the top edge of the locker in effort to adjust my position, I was actually grabbing the inside edge of the hatch. It quickly came down and latched. I had no way out, but was not panicking, I figured I could undo the latch nuts on the inside, but they were just spinning. The only two people I had seen in the yard were a few rows away, both diligently operating electric sanders on their boat bottoms. I called and banged on the hull to attract their notice, but to no avail. Luckily, I had my phone in my pocket. I held off calling the authorities for about 15 more minutes, waiting for the sanders to be shut off (these guys were apparently very focused on their work). Finally, I caved and made the call. About 2-3 minutes later the sanders were shut off, and my efforts were heard. As the two men, covered in paint dust so they looked like blue Smurfs, helped me out of the locker, the Fire and Rescue truck pulled up. Yes, I was a little embarrassed. No more do I enter a locker without hooking a short bungy to it, as I always think about what could’ve happened had I been out on the water by myself. The Smurfs offered me a cold beer, and no way I was going to say no.

Ed White

Taffy 3, Hunter 33-2

Hull, MA

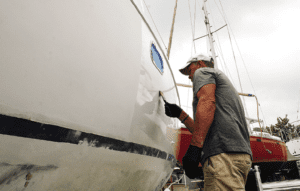

A FAST BOTTOM

Regarding your recent report on fast bottom paint finishes (see “A Fast Finish,” PS March 2019), I sail my Beneteau 321 in the Great Lakes, so we are always in freshwater. We race and sometimes cruise. We sail 50+ days a season. When the yard pulls the boat out of the water in the Fall, we inspect the bottom for marine growth. Generally there is very little. Then the yard pressure washes the hull. In the spring we use Interlux VC 17m, which is a hard thin-film paint that produces a smooth finish. One advantage of VC 17m is very little paint build-up. We scuff sand the hull with 3M ScotchBrite maroon pads. We do the job by hand. Sometimes we use ScotchBrite green pads if I want to remove a bit more paint. We keep the pad wet and frequently rinse it in a bucket of water. We spread plastic tarps under the hull to catch drips.

We mask the waterline with one- or two-inch blue 3M tape. We find that it does not take that much time and effort to scuff-sand the whole bottom. Then we rinse the bottom with a hose. Then we apply a thin, single coat in areas that need it. We generally apply the VC 17m in a band two feet below the waterline, in the bow section, and on the forward edge of the keel. We use less than two quarts. Every two or three seasons, we may feel the need to apply a coat of VC 17m over the whole bottom. Then we use three quarts. The price of VC 17m in the Cleveland area is currently about $90 a quart.

For brushes we typically use a mixture of 1/4-inch nap full-size rollers and foam brushes. The whole job—from masking to painting—in one day with myself and two crew members. If I only have one assistant it can take two days. The process that I described is used by many other sailors in the Cleveland area. We have been very satisfied with the results

Mark Corson

Moya-Manzi, Beneteau Oceanis 321

Cleveland, Ohio

D.R.:

Am researching some alternative coatings for use on spars and related fittings. Not hard surface coats, waxes etc Spent the morning trying to get hard intelligence on 303 Marine Corrosion Coat and related spray on wipe off protectants safe on spars painted and unpainted. Nano coatings? Magic Wands? Have you tested any of these newer products?