Last month we looked at some get home “kludges” if your rigging fails. Here I’ll share some other quick fixes to get you home when things go wrong. All you need is a little twist

The No Solder Twist

The outboard charging harness tears apart on your daysailer. Although a sealed crimp connector is the right answer, you didn’t have the parts.

Kludge. Don’t just twist the wires together; you might not even make it home. The Western Union Splice is the gold standard for splicing solid wire without a crimp.

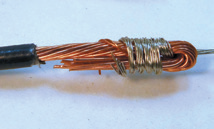

Unfortunately, by code, boats only use stranded wire, and the Western Union Splice is weak with stranded wire. It also takes a lot of wire. Instead, bend one of the wires double with a loop at the end, thread the other through the opening and wrap the tail around the double wire at least 3 turns (see image below right).

Tape thoroughly and replace with a crimp when you get home. In previous testing, we referred to this as a half-lineman’s splice (“Connecting Small Wires, Part II,” PS December 2016).

Plumbing

Stainless clamps are often low grade or have carbon steel parts (see hose clamp report PS August 2016). Often they rust on the side you can’t see.

Kludge. Your spare clamps should all be the same width, so that they can be chained together to fit all sizes. Alternatively, rigging wire can apply considerable tension if each turn is snugged independently by snubbing after each turn, like a running tugboatman’s hitch. Even polyester cord or whipping twine will do. Pulling with vise grips helps.

First, form a tight loop by twisting with pliers around a Phillips screwdriver. Then make as many wraps as possible, in alternating directions every 60 degrees, pulling hard with vice grip and then locking off by bending over sharply through the loop.

Chafed Hose

Lots of tape works for a suction leak on a cold water hose, but not if there is significant pressure or if there is heat or petroleum (the adhesive melts away). Instead, cut a slightly oversize piece of rubber from another hose (surely something is too long) and clamp it over the bad spot using a row of metal hose clamps with no gaps between them.

The stiffer the hose, the better this works, and it’s best if you catch it before it actually blows. Also very good on pipes. If you’re going to keep a sheet of rubber in your kit, 3/16-inch fabric reinforced nitrile is most versatile.

Drew Frye is technical editor of Practical Sailor, he blogs at his website www.sailingdelmarva.com.