Photos by Jonathan Neeves

In recent years, our chain tests (see PS September 2006, July 2007, and July 2008 online) were limited to G30 and G43 (high-test) chain. Our conclusions were pretty straightforward: We would avoid stainless steel for several reasons, the most persuasive being its tendency to fail without warning-as our test sample did. Recognizing that corrosion is what ends the life of most chains, we were not convinced that shelling out more money for the extra strength of G43 chain made sense. It lasted no longer than G30.

Part of the reasoning behind our recommendation of G30 chain over similarly sized G43 was the idea that G30 chain is trouble-free; examples of failure are notable by their absence. However, we did find generic Chinese G30 chain to show an increased corrosion rate over American chain. Now, as in the past, our preference is for brand-name chain made in the U.S., which tends to have more stringent quality control than imported steel products. These days, however, it is getting harder and harder to distinguish between the two, since questionable raw materials often come from abroad, even for those chains fabricated in the U.S.

Since those previous PS tests, interest in higher-grade, hot-dip galvanized G70 chain, with nearly twice the minimum tensile strength of G30 chain, has been building here and abroad. It is being sold in the U.S. by West Marine, the nations largest marine retailer, and Internet discussion boards are filled with questions and advice about it.

We tend to think of anchor chain as an old and well-established industry without much room for technical developments-except perhaps in the world of coatings. This is far from true, as the increased interest in G70 galvanized chain demonstrates.

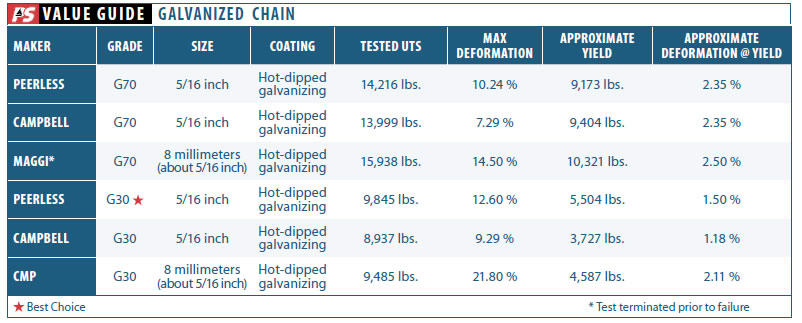

Hoping to dispel some of the myths and to feed our own curiosity, we decided to take a closer look at the trend toward small-diameter, high-test chain. For details on the testing process, see the accompanying How We Tested. Results of our break testing appear in the Value Guide table.

Know Your Gypsy

When buying chain, there are two things to look for. The first is quality, which we hope to explore through our testing. The critical question, though, is: Does the chain fit your gypsy? If not, does it fit a replacement gypsy that fits your windlass? The best way to know for sure is to take your gypsy with you when you buy the chain, and check that it fits. If there is any question at all, you will want to test a length under load on your gypsy to make that it doesn’t slip and that it strips easily into the chain locker. If the chain maker wont let you have a length to test, it is worth buying a short length for testing. Another option would be to send a piece of a chain that fits your gypsy to the chain manufacturer to see if it has a match.

Most modern windlass manufacturers have interchangeable metric and U.S. standard gypsies. However, BBB and G43 chain in the same U.S. standard size use different gypsies. And in Europe, 10-millimeter chain meeting the DIN standard wont fit on the same gypsy used by 10-millimeter chain meeting the ISO standard. The size differences arent always readily apparent, so the only way to know for sure is to physically check.

G70 Chain and Hydrogen Embrittlement

All G70 chain is quench-and-tempered chain. Its strength is imparted by heat treatment. Unfortunately, the heat of galvanizing, about 860 degrees, degrades that strength. The published ultimate tensile strength (UTS) for galvanized G70 chain is about 15- to 20-percent lower than the UTS for ungalvanized G70 chain.

A second issue, and one that causes PS some anxiety, is that acid-washed, quench-and-tempered steels can suffer from hydrogen embrittlement. In simple terms, hydrogen embrittlement is caused when hydrogen atoms from the acid-washing process migrate into the steel, form new, larger molecules that can stress the steel, and cause micro cracking. In extreme cases, these micro-cracks can cause catastrophic failure.

Acid washing of steel to prepare it for a typical coating is usually cheap, easy, and effective. The galvanizing process, however, is not simply a coating process, but an alloying process that demands particularly clean steel, clean enough to allow for the Zn/Fe alloy. The acid-washing process-if it is used at all-for hot-dip galvanizing requires special attention. The problem of hydrogen migration into the steel can be removed, or minimized, by sand-blasting instead of acid-washing, and/or by altering the galvanizing batch chemistry. Both processes are expensive and demand skill.

All of the chain makers we have contacted that are galvanizing G70 told us they are aware of hydrogen embrittlement and are using their own proprietary techniques to avoid the problem. Of particular interest was the distinct differences between the appearance of the galvanized products in our test.

Hydrogen embrittlement is a specific problem where there are large surface areas involved (threaded bolts) and where the steel is stressed (over-torqued, for example). Most catastrophic cases of hydrogen embrittlement are fairly well documented and have involved cheaply produced high-tensile nuts and bolts commonly from imported sources. Products from India and China seem particularly prone to failure, perhaps because techniques of mitigating the problem might not be well known, or not specified, in some factories in order to save cost.

We know of no reported failures caused by hydrogen embrittlement in galvanized, quench-and-tempered steels used in anchor shanks or G70 chain. Currently, the products being pushed into the recreational marine market are made in America, Italy, Scotland, Australia, and New Zealand, where the embrittlement problem is well known and addressed in manufacturing. The danger lies in G70 steel undergoing a less-than-meticulous galvanizing process in factories where quality control is below standard. For this reason, we are wary of galvanized, high-tensile steel bolts made in China-some of which are being used in anchor shanks.

If you buy galvanized G70 chain, you should be aware that it should never be re-galvanized. Although plants that re-galvanize chain are not as abundant in the U.S. as they were 30 years ago, re-galvanizing services still exist in many major cities. Not being able to renew chain when its anti-corrosion coating fails is another noteworthy downside of G70 chain. For this reason, we are putting particular emphasis on part two of this test, which examines resistance to abrasion and corrosion.

What We Tested

There are only two established suppliers of galvanized G70, short-link chain compatible with a standard U.S. windlass gypsy: Peerless and Campbell. However, only Peerless, through its subsidiary Acco, offers galvanized G70 in standard U.S. sizes. It is sold exclusively through West Marine. (The galvanized G70 is not even in the Peerless catalog.)

Peerless claims to have the largest chain galvanizing facility in America. In addition to chain, it manufactures a complete range of marine chain components, shackles, and swivels, and these are just a portion of its product line. The company supplies a very complete cross-section of products to the transport, lifting, and fishing industries, producing everything from decorative chain to G100 high-tensile chains.

Peerless manufactures a complete range of marine galvanized short-link chain, BBB, G30, G40/43, and G70, but also sells imported chains and components. It is best known in the leisure marine industry for the Acco line, available through several major marine retailers. Sizes for the Peerless G70 range from a quarter-inch to 3/8-inch. Peerless makes G70 in larger sizes, but apparently, there is not enough demand for them to fabricate galvanized chain in these sizes. Peerless suggests that its link dimensions are close to a G43 sizing. We have not yet tested the G70 in a windlass, so we cannot comment as to its compatibility.

Maggi is a family-run, Italian manufacturer of marine anchor chains. Along with Peerless, it is the only regular manufacturer of galvanized G70 chain. While many European companies have turned to importing chain from China, Maggi continues to produce its own galvanized G40 and G70 (marketed as Aqua 4 and 7).

Maggi uses a proprietary galvanizing process-the company did not share details with Practical Sailor-and sells in Europe, the Pacific Rim, and Asia. We were told that the company is looking at the Caribbean and American markets, but its current offerings are all in metric sizes.

Maggi offers chain from 8 millimeters (about 5/16-inch) to 16 millimeters (about 5/8-inch) in both DIN and ISO link dimensions, which are identical except for the 10-millimeter size. Although some 8-millimeter metric chain will fit 5/16-inch U.S. standard gypsies without modification, you can’t assume that this is always the case.

Maggi also produces a number of other specialized chains, such as tire chains, snow, and drive chains for motorcycles.

Campbell, the other American marine chain maker, supplied us with short-link galvanized 5/16-inch G70 chain. It has not been introduced into the U.S. market at this time.

Campbell is part of the Apex Tools Group (known internationally for its Crescent range of hand tools). Campbell produces a whole gamut of chain products and pioneered the introduction of G100 high-tensile chain. Campbells marine chains primarily cover galvanized G30 and one size of BBB. However, the company supplied us with a complete cross-section of short-link chain. The Campbell representative said this product could be made available for retail if there is enough demand for it. Campbell tends to be lower profile in the marine industry than some of its competitors and sells through distributors, including 1st Chain.

Canada Metals Pacific, also known as CanMet and CMP Global, is known internationally for its Martyr range of sacrificial anodes, and more recently, as the supplier of the Rocna anchor. CMP manufactures a range of marine galvanized anchor chain in a factory in Ningbo, China. The CMP chain is sold under the Titan brand and includes G30, BBB and Grade L, and G40/43 chain, meeting most American, European, and Australian gypsy sizes. Under the Titan brand, spliced mixed rodes, nylon/chain, and shackles are also available.

Findings

We tested the ultimate tensile strength (also know as the breaking point) for Peerlesss G70, Campbells G70, and Maggis G70 (called Aqua 7). We chose to look at 5/16-inch (8-millimeter) sizes, since that is what a 30- to 40-foot sailboat would likely use and it is easier to handle than larger sizes.

All of the test data appears in the accompanying Value Guide table. To put our testing into context, we also tested G30 chain from Peerless, Campbell, and CMP. All of the G30 chain we broke far exceeded the minimum specified tensile strength for G30, and some approached the supposedly stronger G40 specifications.

The breaking point for our G30 samples varied from 8,900 pounds to 9,800-the minimum specification for G30 is 7,600 pounds. Each sample typically had an approximate yield stress of 2 to 2.5 times the minimum working load limits. Yield stress is the point at which permanent deformation occurs. Maximum deformation varied from 9 percent to 21 percent at failure and 1.2 percent to 2.1 percent at yield. (We have more G30 chain to test, notably from offshore suppliers, and will report in detail in an upcoming issue.)

The Peerless G70 broke at 14,216 pounds, meeting the West Marine specifications, but falling short of those suggested by Peerless.

The Maggi G70 sample achieved a minimum tensile strength at 15,938 pounds, although its UTS will be higher. Our equipment reached its upper limit before the chain broke, but we plan to repeat the test.

The Campbell G70 achieved a UTS of 13,999 pounds. Campbell does not give specs for its galvanized G70.

Based on a 4:1 safety factor, the G70 chains would have an actual working load limit of around 3,500 to 4,000 pounds, compared to 2,000 to 2,500 pounds for the G30 chain we tested.

The Maggi G70, based on yield strength, remains the standout performer, followed by Peerless and Campbell. The difference in yield strength between the latter is too small to pick a winner.

Examination of our test samples after breaking helped to dispel at least some of our fear that high-tensile chain is more brittle than milder steels, and thus less able to withstand snatch loads. A review of the deformation data indicates that G30 chain can be as brittle as a G70. G70 chain stretched as much as G30 chain, although the amount of stretch varied by manufacturer.

PS has always recommended G30 chain over G43, and our testing of G30 for UTS underscores this. G30 supplied by a reputable company is much stronger than its minimum specified rating, and history suggests that chain manufacturing is consistently good.

Galvanized G70 does not have the long history of use to support it. Furthermore, in our testing, the samples only marginally met the advertised specs. (There is no widely accepted specification for galvanized G70).

The idea that G70 enjoys a strength advantage of 7:3 (or around 2:1) over G30 is not entirely valid, and the actual strength advantage as we have found is closer to 1.5:1. You could argue that the high numbers for G30 suggest that some sailors are being overly conservative by upsizing to larger-diameter chain, but that is a complicated discussion (particularly with regard to scope and how it is used), and our test did not focus on this.

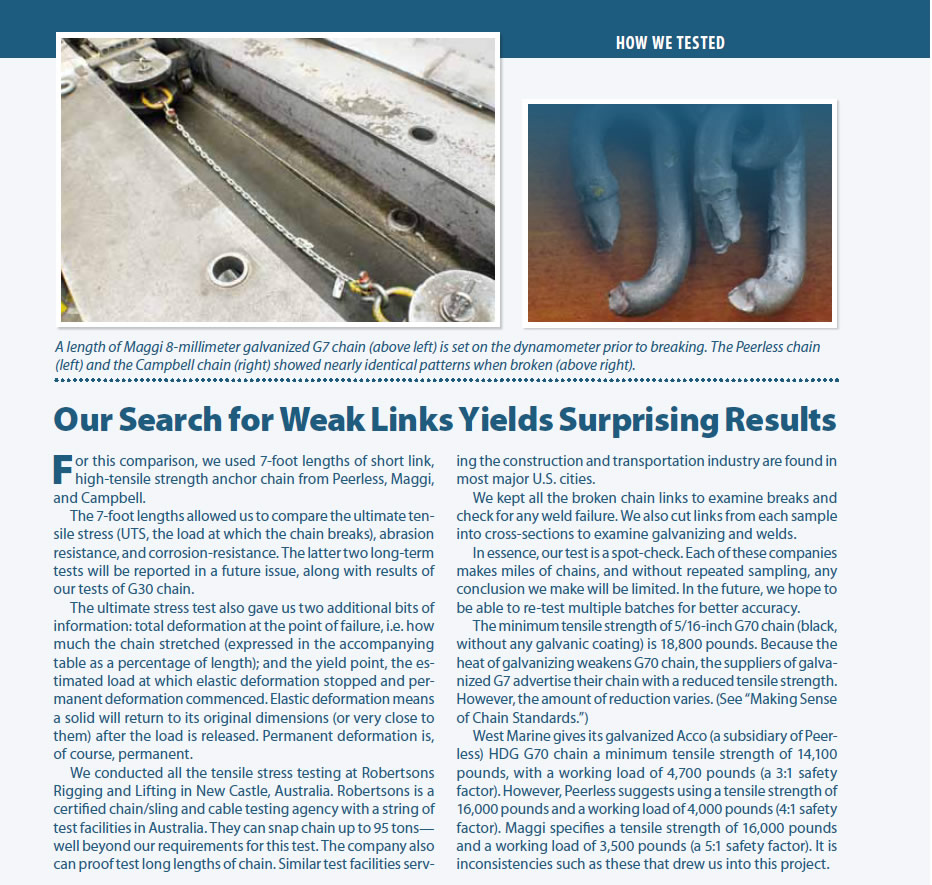

In addition to quantifying ultimate tensile strength, we also looked at the quality of galvanizing and the actual failure of the chain links. We did not break the Maggi chain; we will repeat the test with the retained sample, but both the Peerless and Campbell G70 chains failed at the crown in an identical manner. There was no evidence of any cracking of the weld. Our microscopic examination of all three welds show them to be excellent with no flaws.

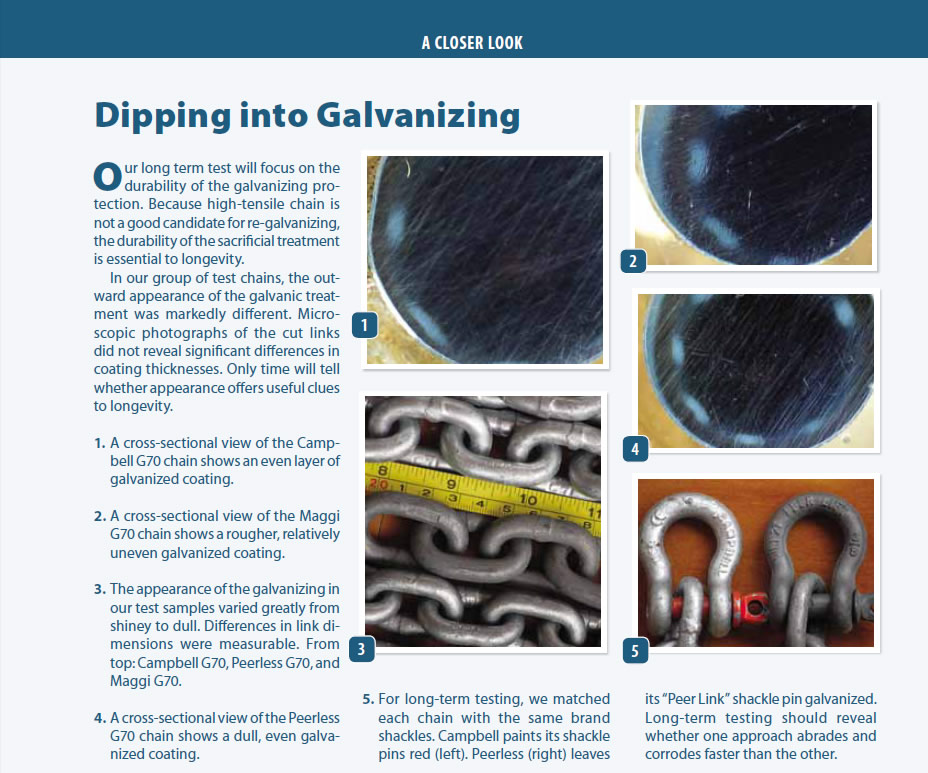

The appearance of the galvanizing of the three products was entirely different. The Campbell sample looked like a conventional piece of new, hot-dipped galvanized metal: bright, shiny metal with some rugosity. Some of the galvanizing layer of the broken link had flaked off, but we don’t think that we would see this effect under anchoring loads. The Maggi sample had a duller, smoother finish. The Peerless sample had what looked like a smooth, matte finish.

Microscopically, the galvanizing layers looked very similar, but differences might become apparent when we complete our abrasion and corrosion tests.

One final note, worth repeating: There is little point in buying a high-strength chain without equally strong shackles that fit both chain and anchor. For a G70, 5/16-inch chain with a UTS of 16,000 pounds, you will need a shackle with a WLL of at least 4,000 pounds.

Campbell and Peerless (through its Peer Link range of shackles) produce galvanized lifting shackles, 3/8-inch, with working load limit of 2 tons. Because they are lifting shackles, they have shorter shackle pins, but they comfortably fit 5/16-inch chain and a modern 50-pound anchor. Lifting shackles are commonly sold on the basis of a 6:1 safety factor and are batch proof tested, making them an intelligent choice.

Conclusions

As the Value Guide table shows, G70 galvanized chain clearly is much stronger than G30, but because current G30 production is so good, the difference between G70 and G30 is not as great as we initially assumed. Many proponents recommend G70 on the theoretical premise that it is twice as strong as G30. Our actual testing shows that G70 is only about 50 percent stronger than G30, primarily because G30 is being made to strengths well beyond specifications. Existing lines of G30 appear to be testing well above the minimum standards-and this might account for its excellent track record.

Based on our test results, we can’t understand why anyone in good conscience would recommend a wholesale replacement of G30 with a smaller-

diameter G70 chain that meets the same minimum specifications. This advice seems even more dubious when we consider the challenges of galvanizing high-tensile steel, the almost certain need for a new gypsy, and the risks of re-galvanizing G70 chain.

That said, we are not banishing G70 to the anchor rode waste bin. The Maggi product tested out as extremely strong, and our research indicates that fears over hydrogen embrittlement might be overblown-at least with regard to reputable manufacturers.

We acknowledge that there are cruising sailors who are watching every ounce, and in time, we may have enough confidence in high-tensile chain to recommend it to those who are cutting their toothbrushes in half to save weight.

For the moment, anyone considering the purchase of G70 chain should demand that it be proof tested, tested to two times its working load limit. We would also recommend purchasing a few extra meters from the same batch to have it independently tested twice for ultimate tensile strength. Proof testing and UTS tests are quick and not that expensive, and they will offer simple peace of mind.