The gold standard for securing deck hardware is a sturdy through bolt with a hefty backing plate. This assumes you can access the reverse side and that you don’t mind the industrial appearance of nuts and backing plates visible on the overhead. But what if we are mounting directly to the inside of the hull, to a hull liner, spar, or area of deck where the reverse side is inaccessible? Installing water pumps, fuel filters, grab rails, water tank retaining straps, stove brackets, electrical panels, rod holders, and turning blocks for windvane steering lines are just some examples of our own fastening projects that have been hampered by lack of access to the back of the mounting surface.

Even if we have complete access, installing a simple through bolt poses other challenges. The edges of all holes in cored areas must be sealed to prevent water intrusion (see “Bulletproof Sailboat Deck Hardware,” PS June 2022). Screws in cored surfaces also need an extra step since the outer laminate skin is too thin to support most screw-on accessories (see “A Stronger Screw Hole Repair,” PS June 2020). Are there fastening methods that might allow us to skip these extra steps, or to reduce the chance of leaks?

In this report we’ll look at the three principal through bolt options for fastening accessories or deck hardware: threaded inserts and backing plates embedded in the mounting surface (deck, bulkhead, etc.); blind fastening systems that function like through bolts, but don’t require access from behind; and bonded fastening systems that are glued to the mounting surface. Each of these methods has its pros and cons, but over the years, we’ve found them to be a handy solution to many onboard fastening puzzles.

BLIND FASTENERS

Blind fasteners come in several different varieties. They are “blind” in the sense they are hidden from view behind the surface you are screwing into.

TEE NUTS

Functioning like tiny threaded backing plates, tee nuts don’t require a second hand to hold them while you are tightening the bolt. If you can trim your bolt to an accurate length, these can lie relatively flush. This makes them easy to conceal under fabric liners. They can be covered with fairing compound, and a good coat of paint makes them nearly invisible. They are available in a variety of materials, including stainless steel.

Tee nuts don’t provide the load distribution of a backing plate or thick washer, but you can fit them into a fiberglass (or wood) backing plate. The backing plates can be “fished” into place like the threaded backing plate described in this month’s PS Advisor “Backing Plate and Self-tapping Screw Tips”.

The most common type of tee nut has teeth formed into the flange. The teeth bite into soft materials, like wood, to lock them in pace. They are also available with less aggressive teeth for fiberglass and soft metals. Some tee-nuts screw into place.

Bottom line: Tee nuts are well-suited for fiberglass, hardwoods, Azek board, and Starboard (see “Is Azek the New Starboard,” PS December 2021). Holding capacity is equivalent to a nut with small washer.

BLIND RIVETS

Commonly known as pop rivets, these rivets are often met with derision. Yet we see them serving well on beach cats that have been abused for decades. In fact, for metal less than 1⁄8-inch thick, they can be an excellent fastener. In thinner metals, they can be combined with thin backing plates. We also see them used to join fiberglass panels, but with limited success. For strength, the rivets should be pulled up through a washer (3⁄16-inch inside diameter), which serves as a backing plate.

Bottom line: In terms of reliability, these rivets offer very little advantage over a through bolt. When a through bolt is not an option, however, Monel alloy rivets, in particular, can fit the bill (see “A Riveting Report: Spar Fasteners,” PS September 2018).

RIVET STUDS

Like blind rivets, rivet studs (paired with a matching nut) are expanded into a hole using a special tool which comes in the kit. These are excellent for mast gates and other hardware that may be removed for frequent service. Although they’re no stronger than a machine screw or a good rivet, they are more durable and less prone to stripping with repeat use. Use anti-seize on the threads; if they seize, they will spin, after which they are hard to remove.

Unless you get the countersunk variety, there is a slight gap between the flange and the mounting surface. If you add a thin mounting gasket, this will prevent it wobbling.

Bottom line: Rivet studs are a good option for mounting electrical panels or switches after the original screw threads have been stripped.

THREADED INSERTS

Like tee nuts and Rivnuts, threaded inserts for wood or fiberglass provide metal threads that are strong and will withstand repeated use. Unlike tee nuts, you do not need access to the reverse side. Unlike Rivnuts, they do not push fully through the mounting surface, so the mounting surface can be of any thickness.

To install, just drill the appropriate size hole and screw in the Rivnut (we prefer the Allen head type for ease of installation). Different thread designs are used for soft wood, hard wood, and plastics. If the wood is soft, bedding the insert with epoxy improves durability. We’ve used these successfully to reattach ceiling liner panels that were fixed with wood screws, after the screw holes wore out. The larger threads make them stronger than the original wood screw; and the connection lasts longer because the wood is unaffected by repeated screwing and unscrewing.

Bottom line: If you need variety, consider threaded inserts. They are available in metric and US dimensions from #6 to 3/8-inch and sold in packs of 10-40 for about $0.25 to $1.50 each. For brass, plated steel, and stainless steel, the price per pack ranges from $2.00 to $3.50. McMaster Carr (www.mcmaster.com) offers a dizzying variety of threaded insert possibilities.

HOLLOW WALL ANCHORS

Hollow wall anchors are familiar to most people who have mounted heavier objects in drywall. The most common kind is the spring toggle. The toggle is threaded onto a long bolt, pushed through a hole about twice the size of the fastener, and then springs open as soon as it is through. Don’t snicker. The high-quality stainless-steel wall anchors, properly sized, can be a valid solution to many mounting puzzles. You need enough room behind the mounting surface for the longer bolt and toggle.

Hollow wall anchors can be quite strong and are suitable for blind fastening light duty items. Strength is contingent upon the strength of the bulkhead or deck they are fitted to.

Bottom line: These are more useful than we imagined. Some installations will meet the marine industry standards for a handhold (400 pounds), but they should not be used to secure a clip-in point for a safety tether or for jackline hardware. Buy extras since it possible to lose them inside the wall.

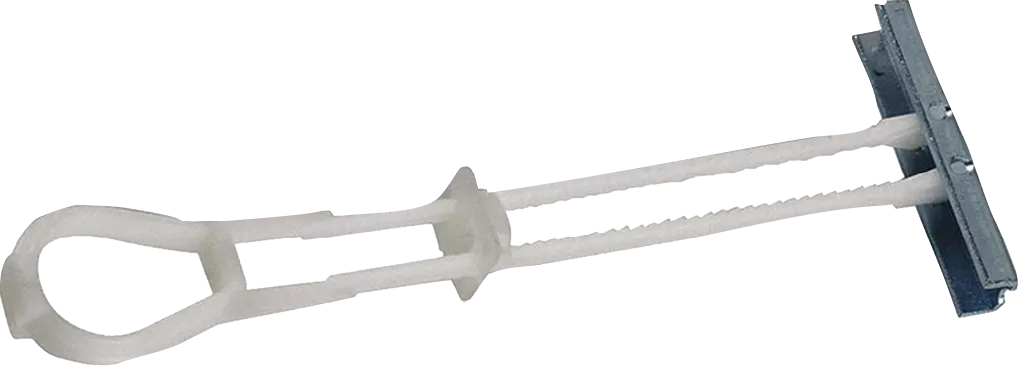

TOGGLER SNAPTOGGLE

Available in 304 stainless and in sizes from #10 to ½-inch (and metric), these heavy-duty toggle fasteners resemble a conventional spring toggle, but without the hinges and springs. You employ a plastic installation handle to maneuver a solid, threaded channel into position. This eliminates the weak point of the hinge. The plastic handles are snapped off before final tightening, leaving only the stainless backing channel in place.

Marine hardware manufacturer Garelick rebrands these and marks them up for mounting seats and pedestals. They recommend a minimum deck thickness of 3/8-inch, but do not specify the layup or core material.

Bottom line: These toggles are nearly as strong as the fastener itself. Prices range from $5-$20 per toggle.

WINGITS MASTER ANCHOR

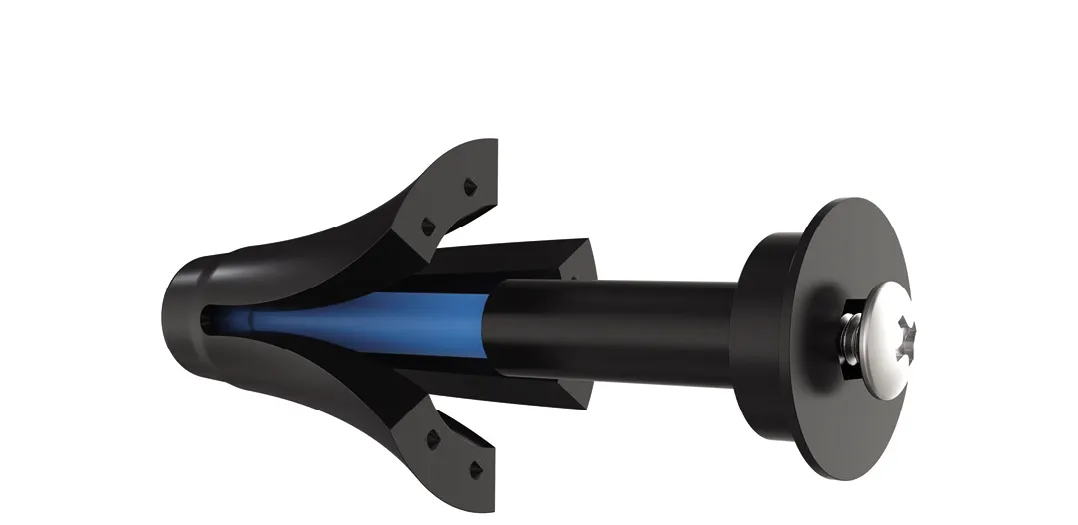

The WingIts Master Anchor is a variation on the familiar expanding anchors used in concrete and drywall. You simply drill a hole to match the threaded insert, push the anchor into the hole, and screw. The anchor expands to lodge firmly in the wall.

Bottom line: The plastic and stainless super-duty type is durable for securing cabin hardware. We recommend it for mounting lightweight fixtures. Price is about $30 for a pack of six.

SHOWER GRAB-BAR MOUNTS

A more advanced generation of hollow wall anchors, shower grab inserts are rated for high loads on shower handholds. They are strong. You can hang from them, jump on them, and stand on them. The mounting plate is big, suitable for a variety of high load mounts. Because they are designed for damp environments, the construction is stainless steel. The Moen Secure Mount ($56) and WingIts Beast ($13) are good options, but we prefer the large Toggler for high-load applications because the hole is smaller.

Bottom line: These mounts are ideal for their designed purpose, but for most applications on a boat, a large Toggler will do the job better because the hole is smaller.

SURFACE MOUNTS

Finally, there are adhesive mount fasteners that are glued onto the surface. These require no drilling and create no possibility of leaks but can become a problem when you want to remove them. Adhesives like epoxy, for example, can leave a large scar when removed. However, if you are careful during removal and use an adhesive remover to loosen bonds and dissolve any residue, you can usually preserve the original fastening surface (“PS Tests Adhesive Removers,” PS January 2017). We’ve never had an adhesive mount fastener fail, but every boat we have owned bore the scars of adhesive mounts that were overloaded or poorly installed.

Surface prep is key to getting the maximum adhesive strength for high-load applications. Wipe with xylene and acetone or denatured alcohol to remove any gelcoat wax. Sand away paint or oxidized gelcoat.

If you are bonding to cored deck or bulkhead, remember that the bond between the core and the skin can be as low as 200-300 psi, limiting the strength of glue-on fastenings (see “Ultra Fairleads and Soft Padeyes, PS May 2023). We’ve used adhesive mounts for mounting some very heavy equipment (even a marine AC unit), relying on the large footprint of the adhesive mount to spread the load.

backing block/baseplate secure a Forespar throughhull and prevent it from rotating.

If the laminate skin is thin or the liner is too weak to support the equipment, one option is to mount the hardware to fiberglass laminate and then bond that to the mounting surface. When calculating adhesive strength, estimate about 100 psi working load limit (WLL) for epoxy and 50 psi WLL for polyurethane sealants (see “Glue-On Fasteners,” PS July 2017).

Glue-on studs and nuts are great for mounting solar panels, AC compressors, pumps, and heavy electrical gear to bulkheads and floors. They are also good for gear hooks. The large holes in the base allow adhesive to flow through. You can mount them with thickened epoxy, but fast-cure methyl methacrylate (MMA) adhesives like Devcon MA300 are optimum for the job (see “Boat Repair in the Age of Plexus,” PS August 2022).

For a professional look, you can cut a matching “washer” out of fiberglass to slide over the stud. Bonded in place, this will conceal the stud’s metal base and give them a custom-fitted appearance.

DUCKWORKS STUD

We’ve used the Duckworks stud for a few projects; the problem is that they only have one size (¼ x 1½-inch 20TPI bolt, with a 1¼-inch diameter base). They sell for about $5 each.

Bottom line: A good product, but with limited selection.

WELDMOUNT

Weldmount makes a stud or nut for every need. The downside to the product is the fasteners and required adhesive is sold in bulk, making it expensive if you only need a few.

Bottom line: Weldmount products are a good option for a builder or someone with multiple projects in mind.

BIGHEAD

Like Weldmount, Bighead makes studs and nuts of every type. Unfortunately, they are sold only in the United Kingdom, so obtaining them outside the British Isles is difficult.

Bottom line: Bighead makes a variety of mounts; they are a good choice if you can find them.

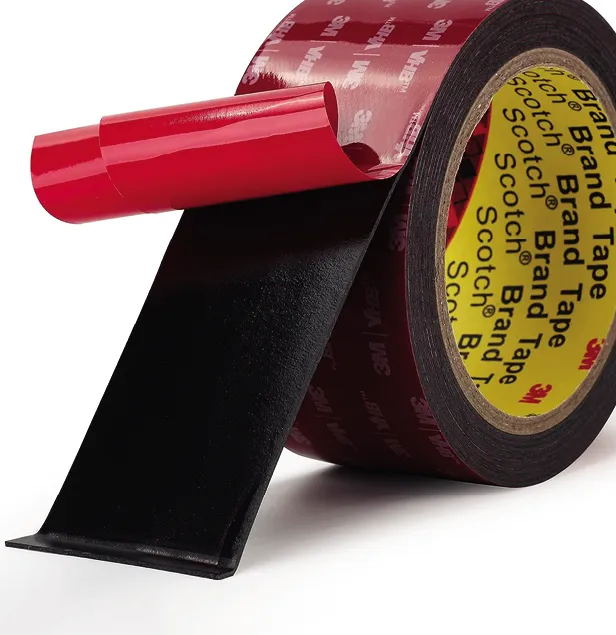

3M VHB (VERY HIGH BONDING) TAPE

Need to mount something that isn’t too heavy, doesn’t need a through bolt, and can be removed without too much prying, scraping, and sanding? Consider VHB tape. Properly applied, this tape holds the windows in skyscrapers. Advertised to “stick instantly,” VHB takes some time to build peak strength and requires meticulous surface prep.

The surface must be completely non-porous. If the gelcoat is old and oxidized, 3M 94 Adhesion Primer, a thin clear sealer that dries in 15 minutes, is recommended. Clean the surface with solvent to remove all wax or dirt. The last wipe should be with denatured ethanol since some solvents can reduce bond strength. Wipe shortly before installing the tape.

Press the tape very firmly into place, applying about 10 psi for several minutes to force the adhesive into the surface. Because the bond depends on the adhesive being able to flow, do not apply below 70° F.

The tape can creep (slip) at temperatures over 105° F, so we don’t recommend it for mounting heavy things in the tropical sun. We’ve had no problem with light loads in the Maryland summer, where temperatures exceed 100° F. VHB tape is rated for short-term exposure up to 300° F.

We’ve mounted fixed windows using 3M 5952, ¾-inch wide, .05-inch thick VHB tape, and sealed round the edges with DOW 795.

Many products are ready-made with 3M VHB tape. We’ve mounted United Yacht Manufacturing’s convenient stick-on line hangers (see “Line Stowage Bags and Hooks,” PS December 2022), stick-on YKK SNAD snaps, signs, and light interior trim.

The tape is rated for mounting on plastics with a relatively medium surface energy. This includes polycarbonate, acrylic, gelcoat, and hard PVC. It won’t work on low energy plastics like polyethylene. It can sometimes hold on to soft vinyl. Price is $20 for 15 yards of ¾-inch tape.

Which VHB tape should you use? The 3M 5952 family is good for plastics. Thicker is better; try 1 mm minimum thickness for rigid materials. The maximum dynamic strength (brief shock load) for 3M 5952 is about 100 psi in tension (direct load) and 90 psi in shear (side load). The maximum static strength (prolonged load) is 6 psi. Use thicker foam for uneven surfaces. The foam also helps with thermal expansion differentials.

VHB tape can also be useful for temporary attachments. Recently, we needed to test an alternate location for the mounting socket of our tiller pilot and the tape held the mount just fine. You may have to scrape or scrub tape remnants. The tape’s acrylic adhesive residue comes off quickly with xylene, mineral spirits, or acetone.

Bottom line: VHB tape is surprisingly versatile. Remember that grip varies by surface. For gelcoat, plan on a dynamic working load limit of 25-60 psi, and a static load limit of 2-6 psi.

3M DUAL LOCK VELCRO

Once our go-to option for temporary mounts, regular stick-on Velcro no longer impresses us. The stick-on fasteners creep and eventually fall off. Loops attract algae. UV devours the material. The hook-and-loop connection is an imprecise, random, and relatively weak match up. Dual Lock Velcro, on the other hand, is the result of systematic interlocking of rows and rows of molded mushroom heads. It engages with a “snap.” The glue is a high-quality acrylic, and if the surfaces are smooth, it will hold for years, yet still come off cleanly.

Bottom line: Dual Lock does not like irregularities or porous materials, so it’s useless on wood and questionable on rough fiberglass, but otherwise, the applications are boundless. We’ve used it to mount fiberglass window covers and winch handle holders. Price is $46 for 10 feet of 1-inch tape.

Plexus MA300

CONCLUSION

We’ve used all these methods because each is best suited for a particular job. We’ve also seen each of these methods fail. Usually, the failure is a result of poor execution, overloading, and a user who has decided to value convenience or appearance above function.

When determining which fastener is best, evaluate your needs carefully. For example, the choice between riveted and threaded fittings will depend on how frequently you plan to remove the fastened item.

An anchor will never be stronger than the substrate, something to consider when mounting on a cabin liner, which can be weak and poorly bonded. A fastener or mounting system that spreads the load may be essential to your project. Adhesive mounts are an elegant solution to certain problems, but even when these mounts are made of carbon and Dyneema they are not a high-tech substitute for through bolts—especially on cored surfaces. Although the glue will withstand several hundred pounds of load, that load is applied only to the laminate’s outer skin, which can pull away from the core under heavy loads.

For many heavily loaded applications, particularly those that can have dire consequences in the event of failure, there are no substitutes for a well-backed through bolt.

CONTACTS

3M PRODUCTS, www.3m.com

BIGHEAD, www.bighead.co.uk

DUCKWORKS, www.duckworks.com

MCMASTER-CARR, www.mcmaster.com

MOEN, www.moen.com

TOGGLER, www.toggler.com

YKK, www.ykkfastening.com

WELDMOUNT, www.hbfuller.com

WINGITS, www.wingits.com

TECH GUIDE: THROUGH BOLT ALTERNATIVES

| TYPE | PRODUCT | WORKING LOAD (TENSILE) | WORKING LOAD (SHEAR) | VISIBILITY | INSTALLATION | REMOVAL (HARDWARE) | REMOVAL (MOUNT) | PERMANENCE |

|---|---|---|---|---|---|---|---|---|

| BACKING PLATE & THROUGH BOLT | DIY | High | High | High | Moderate | Moderate | Moderate | High |

| BACKING PLATE IN LAMINATE | DIY | High | High | Low | Moderate | Easy-High | Moderate | High |

| THREADED BACKING PLATE | DIY | High | High | Low | Moderate- Hard | Easy | Easy | High |

| ACORN NUTS | Various | High | High | High | Easy | Easy | Easy | High |

| TEE NUTS | Various | High | High | Low | Easy | Easy | Easy | High |

| BLIND POP RIVETS | Various | Moderate | High | Low | Easy | Moderate | Moderate | High |

| SELF-TAPPING SCREWS | Various | Low-Moderate | Low- Moderate | Low | Easy- Moderate | Moderate | Easy | Moderate |

| RIVNUTS | Various | Low-Moderate | Low- Moderate | Low | Easy- Moderate | Moderate | Easy | Moderate |

| THREADED INSERTS | Various | Low-Moderate | Low- Moderate | Low | Easy- Moderate | Moderate | Easy | Moderate |

| GLUE-ON MOUNTS AND ADHESIVE STRIPS | ||||||||

| ADHESIVE MOUNTS | Various | ~75 psi | ~200 psi | Moderate | Moderate | Easy | Difficult | High |

| VHB TAPE | 3M #5962 | 70 psi | 80 psi | Low | Easy | Moderate | Moderate | Moderate |

| HOLLOW WALL MOUNT | ||||||||

| TOGGLER | Toggler Heavy Duty Toggle Bolts, Stainless | Moderate- High | 200 pounds | Low | Moderate | Easy | Moderate | High |

| WINGITS | WingIts Master Anchor, Super Duty | High | 300 pounds | Low | Moderate | Easy | Moderate | High |

| SHOWER GRAB MOUNT | ||||||||

| WINGITS | WingIts Beast | High | 800 pounds | High | Moderate | Easy | Moderate | High |

| MOEN | Moen Securemount | High | 300 pounds | High | Moderate | Easy | Moderate | High |

| ADHESIVES | ||||||||

| VINYLESTER RESIN | Various | 600 psi | 500 psi | Low | Moderate | Easy | Permanent | High |

| POLYESTER RESIN | Various | 400 psi | 350 psi | Low | Moderate | Easy | Permanent | High |

| 2-PART EPOXY | Various | 2,200 psi | 2,000 psi | Low | Moderate | Easy | Permanent | High |

| METHACRYLATE | Plexus MA300 | 2,000 psi | 1,800 psi | Low | Moderate | Easy | Permanent | High |

| POLYURETHANE | 3M 4200 Fast Cure | 120 psi | 100 psi | Low | Moderate | Easy | Difficult | High |

| POLYURETHANE | 3M 5200 | 560 psi | 500 psi | Low | Moderate | Easy | Difficult | High |

There is not a one-size-fits-all solution to every very fastening puzzle. Consider how frequently you’ll need to remove the hardware or fitting you are installing, how much drilling or cutting you want to do, and how much load the fastener will carry. Do not scrimp on anti-seize, especially with Rivnuts and similar hardware that uses friction (and adhesive, if needed) to embed in the fastening surface.

1. A Rivnut stud embeds in the substrate (fiberglass pan liner, wood bulkhead, etc.), requires no access from behind, and allows you to easily remove nuts that bolt on any accessories. Using plenty of anti-seize will prevent the fastener from spinning in the spar.

2. Like the Rivnut stud, a flanged Rivnut (female), makes it easier to remove accessories. These can be used for mast gate hardware and other mast hardware that needs to be removed periodically.

3. The rivet length must allow for the thickness of the spar, the hardware, and the required internal clearance.

4. Use the outside threads on a threaded insert to screw the insert into the mounting surface. Internal threads accept a bolt for mounting accessories.

5. Inserted from the reverse side into a slightly oversized hole, a T-nut will grip softer surfaces like wood.

6. As you tighten the screw on the WingIts Beast, the insert expands to grip the sides of the hole. This one is designed for high-load hardware like a shower grab bar.

The big question when using glue-on surface mounts is how permanent you want that bond to be. Most glue-on hardware solutions will work with various adhesives.

1. Bighead studs will bond to many surfaces using one of several compatible adhesives. Thickened epoxy and methacrylate adhesives (Plexus) are recommended. Although other glues will work, we would not recommend lower strength adhesives.

2. 3M Dual-lock Velcro makes for a simple installation of this home-made solenoid cover. If you don’t like the mounting location, removing the tape residue is not too difficult. It will not stick to porous surfaces like wood.

3. 3M Very High Bond Tape provides a powerful bond. With careful use of a scraper and heat gun, you can remove most of the residue.