Part 1

Almost from the dawn of man, this unique creature has used his ingenuity to make different materials stick together. In fact, this may well have been the first technology, whether used in the making of tools or other necessities.

Archaeologists have removed statues from Babylonian temples – statues with eyeballs glued to their sockets with bituminous cements that held fast for 6,000 years. Paintings found in tombs near the ancient Egyptian city of Thebes dating back about 3400 years depict a gluing operation for veneering. Egyptian mummies were wrapped in linens saturated in resins and waxy gums to protect both the body and wrappings from deterioration (probably the first example of sheathing), while Roman ships were caulked with pine tar and beeswax.

Most primitive adhesives came from tree sap, leaves, bark, roots; and animal hides, hooves and bones. Some adhesives of these types are still in use today, but it was the scientific explosion in the second quarter of this century that provided us with synthetic materials of remarkable strength, uniformity, and reliability. From filter tip cigarettes, which use over a dozen adhesives in their manufacture, to the B-58 delta wing aircraft which utilizes structural to the exclusion of rivets, modern adhesive technology has come a long way.

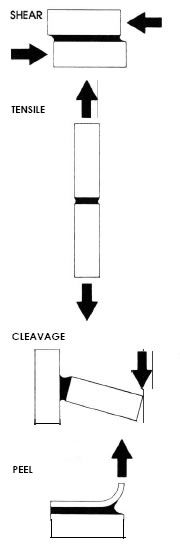

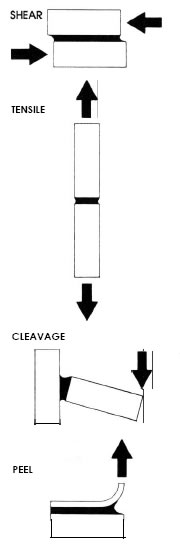

It’s helpful in considering adhesives to recognize that they posses a remarkably unique property – they have no identity by themselves. They are adhesives only to the extent that they bond to some other material or materials. The end-product, a structural element, should be looked upon as a system consisting of two surfaces joined by as adhesive. These structural element or joints – may have a variety of configurations, but all joints are variations of four basic types, as defined but the manner in which they are stressed. These are shear, tension, cleavage, and peel. Since the nature of the stress in a joint has a great influence on the characteristics of the adhesives required to function most effectively in that configuration, before we talk much about adhesives we ought to consider the stresses which must be withstood. The four basic stress modes are indicated below.

180

1. SHEAR. Force is exerted across the adhesive bond. The bonded surfaces are being forced to slide over each other. All of the adhesives contributes to bond strength.

2. TENSILE. Force is exerted at right angles to the adhesive equally over the entire joint. All of the adhesive contributes to bond strength.

3. CLEAVAGE. Force is concentrated at one edge of the joint and exerts a prying force on the bond. The other edge of the joint is theoretically under zero stress. Only a portion of the adhesive resists load.

4. PEEL. One surface must be flexible. Stress is concentrated along a thin line at the edge of the bond where separation occurs. A very small portion of the adhesive carries all the peeling force.

Most adhesives perform better when the primary stress us shear or tensile. However, in most applications a combination of stresses is involved. For best performance the entire bond area should carry the bulk of the stress.

In addition to stress mode, other factors usually influence the selection of an adhesive. Environmental exposure us an important consideration – moisture, temperature extremes, impact, vibration, chemical contact, dimensional changes, and biological attack all impose added requirements on the adhesive.

Next, the application requirements or process limitations must be examined. Is the adhesive easy to use? Are special tools required? A weight scale? How much working life is needed? What is the range of application and curing temperatures? How critical is the condition and fitting of the surfaces? Is clamping pressure important to the ultimate strength? Can dissimilar materials be bonded?

Finally, the nature of the cured product is of concern. Is color important or will staining detract from the finished product? Will the adhesive be compatible with materials applied later? What is the anticipated life under the expected service conditions? Having outlined some of the requirements that an effective adhesive must meet, we can now open the chemist’s cupboard and se what he has to office. Most home built boats and project aboard a boat are made of wood, Mother Nature’s very own reinforced plastic. Thus, most of the adhesives we find are primarily intended for bonding wood, and since boats are usually used in the water the adhesives we find are primarily intended for bonding wood, and since are usually used in the water the adhesives are waterproof. (The chemical mechanisms by which the adhesive becomes and remains insoluable in water are the responsibility of the chemist, and we can fortunately leave his witchcraft to him).

Three major types of waterproof of waterproof adhesives are available today, and we identify them by their approximate chemical names: resorcinol, ureaformaldehyde, and epoxy. Several other adhesive sealants are available (silicone, polysulfide, polyurethane, polyamide, cyanocrylate, etc.), however, it is beyond the scope of this article to deal with all of them and we will instead concentrate on the tree front runners.

Having already noted some of the characteristics that these adhesives have in common, let us now consider how they differ. Resorcinal adhesives have been available for over 25 years. The adhesive is generally supplied as a powder which is mixed with a specified quantity of water immediately prior to use (two part resorcinol comes as a liquid resin and a powdered hardener). After mixing, resorcinol remains semi-fluid for periods ranging from 20 minutes to 2 hours, depending on the type, and is easily applied with a brush, spatula, or a stick. Most manufacturers recommend that the temperature of the work room, the adhesive, and the surfaces to be bonded should not be lower than 70 degrees F. during application and cure.

Resorcinal should not be used if the wood has a moisture content above 15 percent. It need be applied to only one of the two mating surfaces, and care must be taken to avoid disturbing the joint after 20-30 minutes following clamping. The most critical characteristics of resorcinol are its dependence on of glue line thickness and clamping pressure. The U.S. Plywood Corp. in their Bulletin #400states; “In general, for best results, sufficient pressure to reduce the glue line to a thickness of 0.005 is required. Thicker glue lines will result in an inferior bond… but high pressure should not be substituted for poor fitting joints.”

When relatively thin and flexible wood, such as plywood, is fastened down by screws, there may not be adequate pressure except near the screws. With annular nails rather than screws, the situation is more serious since aone cannot achieve nearly as much pressure, particularly when there is tension at the joint which is to be pulled together.

When hardened, resorcinol tends to be brittle and inelastic, limiting its use to relatively rigid surfaces where peel and cleavage forces are negligible and vibration and impact unlikely. Care must be taken to avoid smears and runs with resorcinol as it produces dark stains on most timbers. In laminated structures which will be exposed to view, the dark color of the glue line may also be objectionable. We should also note that resorcinol does not produce reliable joints with oak, especially if subjected to repeated wetting and drying.

All this does not mean that sound boats cannot be built with resorcinol adhesives, but it does point out that care is needed if one is to avoid building a craft of substandard strength.

Let’s turn now to urea-type adhesives. These are available as both one-part and two-part systems. The one-part system is prepared by diluting with water, much the same as resorcinol. The two-part types are supplied as separate resin and hardener components. The resin may be a liquid to be used as is, or a powder which is diluted with water prior to use. (Perhaps the best known of this type is Aerolite 300 and 306.) The two-part ureas are used in a manner that many might consider unique. Instead of missing the resin and hardener together as is done with polyester and epoxy resins, you apply the resin to one of the surfaces and the hardener to the other. When the surfaces are brought together, the curing reaction begins and proceeds at a rate of dependant on the temperature of the surfaces; the warmer it is the faster the adhesives cures. Urea type adhesives are generally rather slow curing below 50-55 degrees F., and may fail completely if the surfaces are below 45 degrees F.

The wood should be clean, dust-free, and dry. Plywood should be roughened slightly with sandpaper if it appears to have a glaze from the heated presses used in its manufacture. Fit and clamping pressure are not nearly as critical as for resorcinol; glue lines may be as thick as 0.030” (1/32) and clamping pressure need be no greater than that required to bring the surfaces together. As we mentioned, curing begins upon contact, and after about 20 minutes at 70 degrees F., the adhesives has substantially solidified (although not fully cured) to the extent that the joint may not further be closed. In warmer weather, gellation is even more rapid, sometimes necessitating fast work several helpers if scalloped or incompletely closed joints are to be avoided.

Cured areas are light straw colored to transparent and will not produce unsightly stains. Adhesive squeezed out of the joints can be cleaned up with a damp clothe if not permitted to cure too long. When using two-part ureas it is mandatory that panels be marked on the interior before gluing in order to identify mating surfaces for proper application mating surfaces for proper application of resin and hardener. It is particularly important not to omit the hardener or allow it to dry out before mating the surfaces, as the resin portion will merely dry out before mating the surfaces, as the resin portion will merely dry (as opposed to curing) all by itself in a few hours and be almost indistinguishable from poorly cured resin, (except that it will later dissolve in water!).

In Part II, in the next issue, we’ll take a look at the properties of epoxy adhesives.