Gathered on the sofa, I fumbled with the HDMI cable, trying to connect my laptop to our TV.

“What’s this movie about?” Ryder, our eldest, queried.

“Three women who follow the flow of plastics across the North Atlantic Ocean on a 50-year-old wooden catamaran,” I replied.

“Did it sink?”

“I guess we’ll find out.”

I’d been given the privilege of watching a rough cut of solo sailor Kiana Weltzien’s documentary, Women & the Wind, to provide storytelling feedback. Having followed their journey loosely on Instagram, I had my doubts about the seaworthiness of Kiana’s Wharram Designs NARAI, Mara Noka. As I squeezed between my kids and husband Remy, completely unaware of the impact this film would have on us, I turned up the volume.

Ninety minutes later, tears streamed down my cheeks as I turned to Remy and declared, “We have to build a Wharram. It’s the perfect solution!”

“You’re out of your mind,” came the chorus…

CREATING A REGENERATIVE SAILBOAT STUDIO

The “solution” I was referring to was our ongoing search for a vessel to become our Floating Stories Lab; a regenerative sailboat studio. For years, I had flown around the world as a documentary producer, making films about eco-adventure surf travel, conservation and climate change. As thrilling as this lifestyle had been, I hated traveling without my family, and the constant flying felt contradictory to the impact I aimed to achieve through my storytelling. Having crossed Asia overland without plastics from India to Japan with Remy and my then six and eight-year-old sons, via the Himalayas, I dreamt of finding a way to travel with the family again while pursuing my work.

During a shoot in Raja Ampat, Indonesia, an archipelago in the Coral Triangle known for its remarkable biodiversity, I saw a private monohull moored at the dock of an exclusive eco-resort. The crew, a family, asked for anchorage recommendations and permission to dive at some of the Marine Protected Areas managed by the resort’s foundation. Sitting on the dock, overhearing their requests, my head spun with possibilities. Anchorages? Like free places to park your boat in paradise and go diving?

Returning home to France, COVID lockdowns gave Remy and I time to plot our future. As semi-nomadic surfing travelers, living on a sailboat felt like a no-brainer. We’d start sailing lessons as soon as restrictions lifted, research secondhand boats within our budget, and develop the studio aspect to ensure the boat would engage artists and storytellers with science to envision regenerative futures. We agreed this project had to be something much bigger than just us.

Years passed, and our lives were plagued by recurring miscarriages and subsequent complications as we tried to have a first baby together. These setbacks delayed our plans until July 2023, when we were gifted with a daughter, re-centering our dreams to pursue our project.

DISCOVERING WHARRAM DESIGNS

One blistery winter’s day in southwest France, while driving to one of the boys’ soccer matches, I came across an article shared by Juho of Alluring Arctic Sailing on Facebook. The article detailed a groundbreaking study that revealed significant amounts of fiberglass particles in oysters and mussels collected near active boatyards. These findings highlighted not only the environmental impact of fiberglass pollution from GRP boats but also the potential threat to human health. Discovering fiberglass in bivalve organisms like oysters, which are filter feeders and act as the “lungs” of our oceans, suggests that these particles have likely entered our food chains.

Given my background, coming from three generations of Australian surfboard shapers and having vivid childhood memories of experiencing fiberglass ick when visiting my uncle’s surfboard factory, I wasn’t surprised but was deeply concerned. “We absolutely can’t buy a plastic-fantastic boat now!” I declared. Remy, who was then working in the surf manufacturing industry and witnessing firsthand the fiberglass dust waste produced by the industry, agreed.

Our search shifted to steel, and we even made an offer on a well-kept 1985 steel Scorpio 13 cutter rig, which was refused (the young owner had overpaid for the original, elderly owner’s pride and joy and was not willing to make a loss). In January 2024, our project took a new direction when we watched Kiana’s film. I dove into the world of Wharram Designs, discovering the wonderful ethos and practical benefits of these low-tech, wooden catamarans.

THE JAMES WHARRAM LEGACY

James Wharram designed minimalist, wooden double canoe/catamarans inspired by Polynesian seafarers. Influenced by French catamaran pioneer Eric de Bisschop, Wharram dismissed the theory that simple rafts transported migrants to the Pacific Islands, asserting that double canoes with sails enabled migration from East to West.

In 1953-54, James, partnered by two German women, Ruth and Jutta, built Europe’s first successful offshore catamaran, the 23-ft. wooden Tangaroa. They crossed the Atlantic Ocean in 1955-56, but the British yachting world remained indifferent. In 1957, James built the 40-ft. wooden catamaran Rongo in Trinidad and completed the first successful North Atlantic Crossing from New York to Britain in 1959, proving the seaworthiness of his designs.

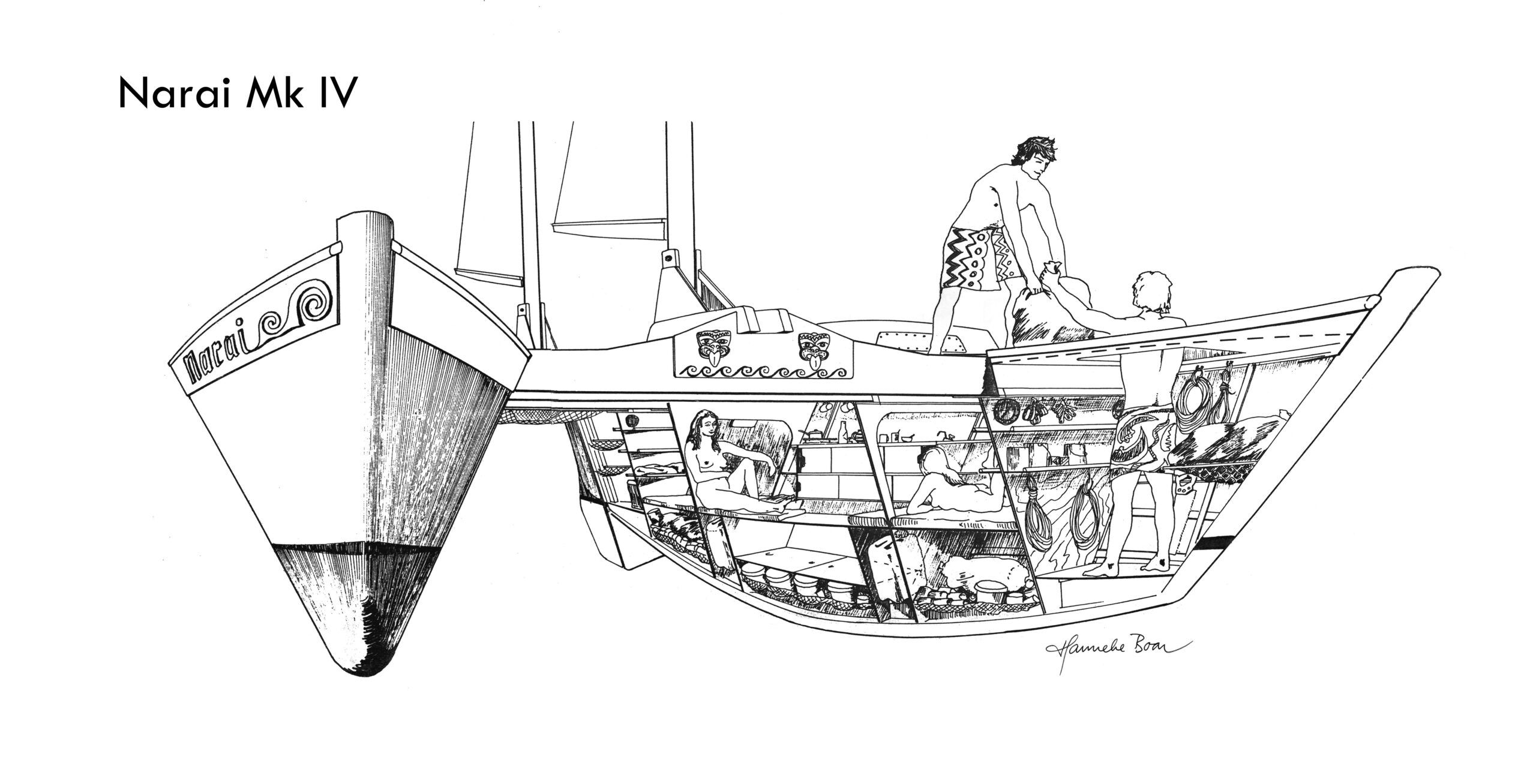

Though James Wharram passed away a few years ago, his legacy continues through his partner, Hanneke Boon. As Head of Wharram Designs for over a decade, Hanneke has supported James and led the company. Born in the Netherlands, she grew up in a sailing family and joined James Wharram’s team at 20. Hanneke’s skills as an artist, graphic designer and boatbuilder have resulted in some of the clearest boat building instruction plans, many of which she has drawn since the 1970s. Through Kiana’s introduction, we were fortunate to be invited to meet Hanneke in Portugal for a week aboard her Pahi 63 Spirit of Gaia, to experience life on board a Wharram whilst discussing our project and choice of design.

CHOOSING THE NARAI MK IV

Mara Noka’s design, the NARAI, is a direct descendant of Wharram’s Rongo. Built 50 years ago from plywood, likely mahogany, with nylon sheathing and tar coating, she spent most of her life in the Mediterranean before crossing the Atlantic to Panama. Kiana, a newbie sailor at the time of becoming her captain, sailed Mara Noka multiple times across the Atlantic before embarking on a major refit. Following the refit, Kiana successfully navigated Mara Noka across the North Atlantic with two women as crew, enduring three low-pressure systems along the way.

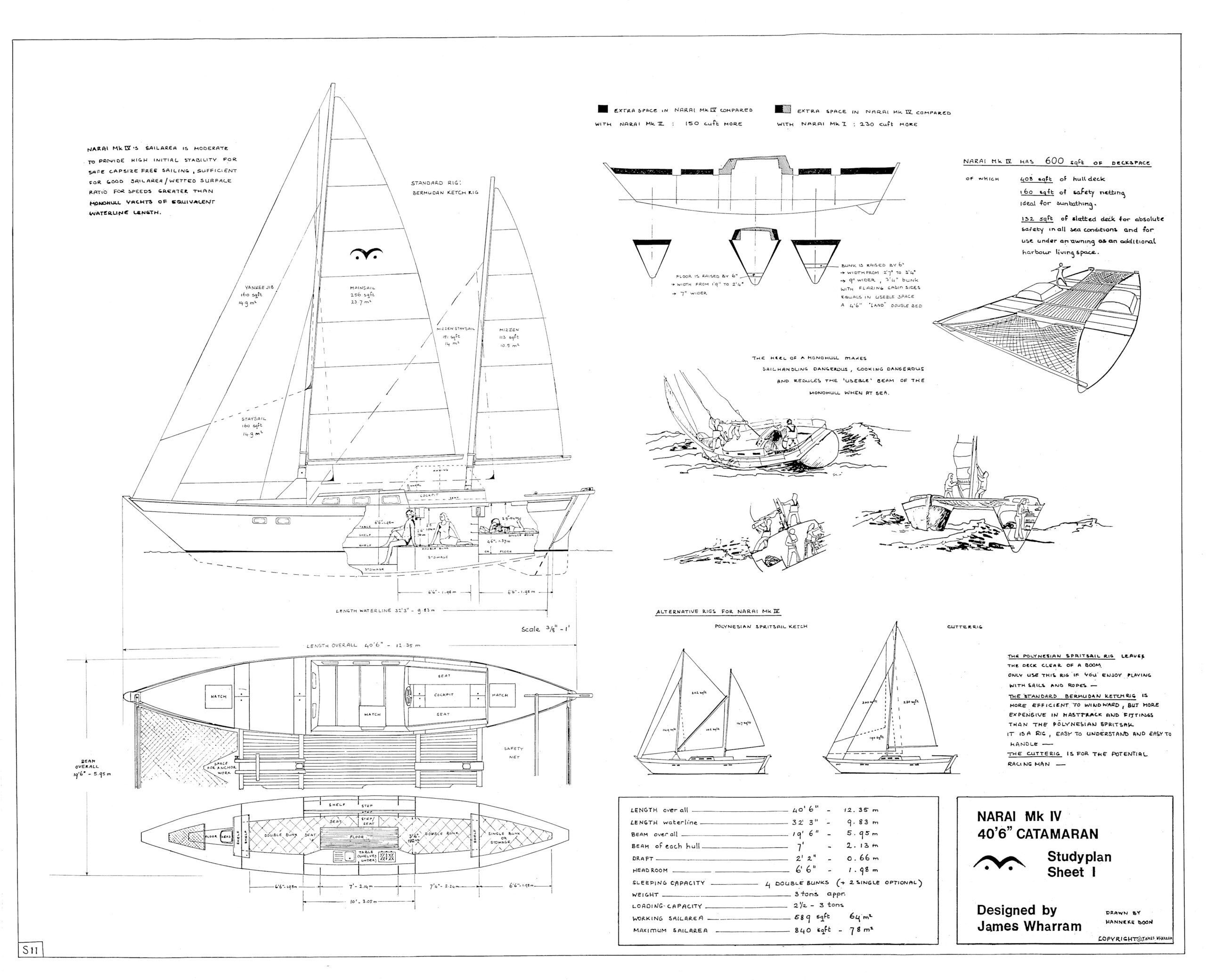

Our decision to build the Narai Mk IV was influenced by Mara Noka’s resilience, ease of sailing, and impressive longevity, as well as conversations with Kiana and our week living at anchor with Hanneke Boon on Gaia. Compared to earlier Narai designs, the Mk IV features wider individual hulls and increased headroom, achieved by raising the decks to the level of the gunnels and placing the cross beams in beam troughs. After years of semi-nomadic living, including a six-month period living in tents on the East Coast of Australia, we were particularly drawn to the spacious center deck that invites extensive outdoor living. Additionally, as inexperienced sailors, the center deck catamaran design provides us with confidence for sail changes and enduring rough weather, avoiding the extensive heeling and minimal space we experienced on monohulls.

Furthermore, the classic designs are known for their seaworthiness as ocean crossing vessels. As a family of five with a dog, and the desire to invite others on board for select voyages, safety and comfort on long crossings is paramount, along with ease of mainteance and fixing problems; our boat will feature two small outboard engines, Wharram’s iconic double masted Wing Sail Rig, and uncomplicated hardware.

Hanneke reassured us that we had made a great choice for our family, project intentions and circumnavigation objectives, whilst she advised us on her reccommended modifications such as improved center deck details, Tiki-style I-section crossbeams, and crossbeam lashing details (these modifications are included in the now-standard Design Improvement Package 2 sold with the Mk IV plans. Wharram Designs does NOT recommend builders to veer from the plans).

BUILDING THE NARAI MK IV AND EXPLORING BIO COMPOSITES

The Narai Mk IV is a classic design made of timber, plywood, and epoxy. Its specs include:

- Length Overall: 41 ft (12.50m)

- Beam Overall: 19 ft (5.80m)

- Draft: 2 ft 4 in (0.71m)

- Headroom: 6 ft 6 in (1.98m)

- Sleeping Capacity: 4 double bunks, 2 single bunks

- Weight (empty): 3.5 tons

- Loading Capacity: 3-3.5 tons

- Working Sail Area: 259 sq ft (49.1 sqm)

- Max Sail Area: 840 sq ft (78.1 sqm)

Building materials outlined in the plans for our Narai Mk IV include marine ply and resorcinol or epoxy glue. The estimated building time is 2500 to 3000 hours, with an approximate cost of around $50,000 for a standard build (this estimate does not include labor, engines, fittings outside plan specifications or navigation equipment).

While the classic Wharram designs initially specified resorcinol glue, epoxy is now extensively used in boat building. Epoxy seals the wood and provides a stable surface for painting. Although the hulls can be coated with epoxy without glass cloth, Wharram Designs advise that using plywood glassed with epoxy and painted with two-part paint is as durable as a fiberglass boat.

Our commitment to exploring less degenerative materials has led us to initiate a pre-build phase of R&D, researching production methods and supply chains to inform our decision-making. A potential alternative to using glass fibers is presented by recent developments in the use of flax fibers in boat building. Lighter than glass fibers, flax offers good results in impact and abrasion resistance. Similarly, linseed epoxy resin, derived from the flax plant, is odourless and gentler on living systems whilst enhancing the durability and waterproofness of the wood. However, we also need to consider factors such as flax fibers tending to absorb more resin than synthetic fibers, potentially leading to a heavier structure. Similarly, we want to source renewable wood species, ideally grown and produced as locally as our budget affords.

We are thus considering bio-composite materials to coat the wooden structure of our Narai Mk IV, aiming for a finish that is durable, long-lasting and visually impressive, while also reducing environmental impact. This approach seeks to preserve the traditional wooden build’s aesthetic and structural integrity. To our knowledge, no one has yet used flax fibers and linseed epoxy resin on a Wharram Narai Mk IV build, making our project both a challenge and an opportunity. We are still in the early stages of research and development, exploring the practical applications and feasibility of these materials alongside the guidance of experienced wooden boat builders such as Wharram Design’s own Hanneke Boon, and Heike Löwenstein of Raindrop Boats.

Wharram Designs are intended to be affordable and built with available materials, and our build should reflect this philosophy while acknowledging the increasing economic costs of high-quality timbers and marine ply, along with their ethical and environmental costs. Ultimately, we aim to build a boat that will take us around the world with confidence, requiring minimal maintenance and lasting for decades. While we are optimistic about the possibilities, much remains to be tested and validated. Our overall goal is to integrate ethically and sustainably sourced bio composite materials wherever possible, without compromising on durability or aesthetics, or taking a decade to splash our future family home and studio.

COMMUNITY AND COLLABORATION

We have decided to relocate to Bretagne (Brittany) imminently to continue R&D and begin our build, positioning ourselves within a strong community of wooden boat builders and sailors, including other Wharram builder/owners. Our journey will be documented and shared, engaging both our digital and place-based communities to share knowledge and exchange ideas. The dream is to embark on a “backyard” build, inviting friends from all over the world to come stay and participate in the build, true to James Wharram’s philosophy that any urban person can, “with a little financial saving, and some handcraft work, create an object of beauty. This object of beauty can then, for a period of hours, days, weeks or months, carry him/her out of urban world and into a natural never-never land; the seas and oceans…”

Finally, when splash day arrives, we envision a true celebration with our communities. We will launch this community-built boat with friends and family, embarking on our circumnavigation, ready to shift our baselines and perspectives in ways only the Ocean can inspire.

Has anyone used Basalt fiber to sheath a Wharram cat? It may offer a high strength, abrasion resistant alternative to fiberglass.

Is there a way to share this article with a friend who does not subscribe to PS?

You can “print to PDF”. There is a Print icon near the title at the beginning of the article.

Wow. What an adventure!