The Art of Maintaining Teak Trim on a Sailboat

As the owner of a modern Beneteau, Jeanneau or a host of other recently-launched dream boats, you’ve probably noticed the distinct lack of teak...

Can Exterior Paint Revive Faded Dodger Canvas?

One of the little luxuries many sailors treat themselves to is great canvas. I just went sailing on a brisk, cold and windy day...

Freeing Seized Hardware

Simple ferrous-metal oxidation is a process in which iron, oxygen, and water chemically react, and it can cause rust to seemingly weld fasteners together. This unyielding grip often turns disassembly into much more of an ordeal, but with a few, regularly available products and a good set of wrenches, the big battle becomes a minor squabble.

Winter Sailing Tips for Diehards

For many seasonal sailors, the winterizing routine is already well underway. But there are more than a few diehard sailors in the mid-Atlantic regions, on the West Coast, and even in New England, who plan to spend all or part of the snowy season afloat. Some, we daresay, look forward to the quiet of winter. If youre toying with the idea of keeping your boat in the water during the winter, heres a short rundown on some of the more important steps to take.

Sailboat Stewardship Tips: How Not To Be “That Person”

Good boats outlive us, or at least outlive our interest in them. In time, we become the dreaded Previous Owner (PO). Will we make this...

DIY Winch Feeder

It was snowing and I needed a project. Ever since the article on cross sheeting, “Where Winches Dare Go,” I’ve been wanting to add...

How To Extend Your Canvas’ Lifespan

Protecting your canvas will extend its life as well as provide you and your crew protection from the sun and elements for many years....

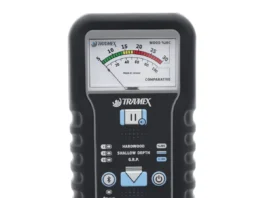

How To Streamline Your Maintenance Program: A Beginner’s Guide

Owning and using a boat is all about maintenance. While maintenance is not fun—it can be filthy and arduous—it must be done if you...

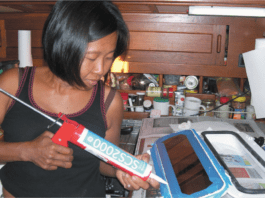

Dirt-cheap Winter Insulation for Liveaboards

Insulation is a greater energy-saving expedient; if our heater or air conditioner is undersized, fixing drafts, shading or insulating windows, and insulating non-cored laminate are all ways to reduce the thermal load. For boaters, however, that is only half of the equation.

Lessons from a Harbor Master

I’ve been a member of my yacht club going on over 35 years now and spent 16 of those years as Harbor Master. Now,...