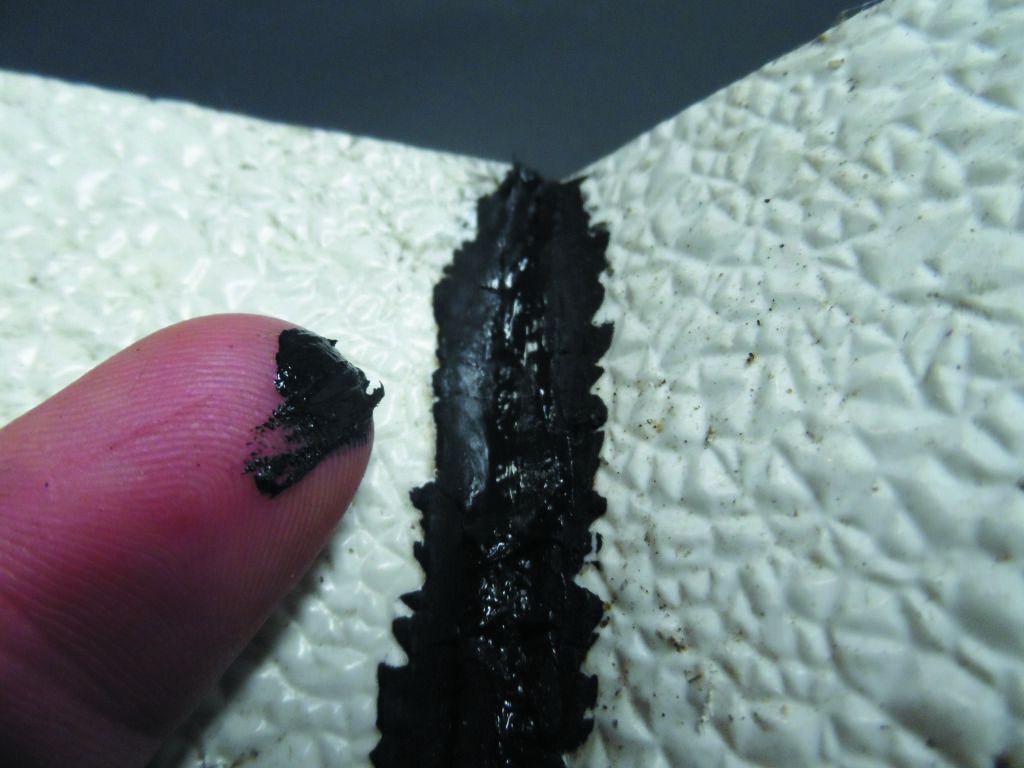

The sudden and complete failure of 3M’s 4000UV adhesive sealant after five years of exposure, discussed in the upcoming December 2021 issue of Practical Sailor, inspired me to review our extensive library of adhesive sealants to determine if it could have been due to an application error. The short story is that it wasn’t. This was the only product among several undergoing testing that suffered this catastrophic failure, in which the product reverted to its original gooey state.

When we reached out to 3M, a spokesperson apologized by email and all but conceded that the product was at fault, writing that the company had revised the formula in 2018. If you bought 3M 4000 caulk made prior to 2018, you’ll want to monitor it for potential reversion failure as described below. We are still looking into this to determine if any other brand caulks were susceptible to this type of failure and will be reporting more in the future.

Choosing the right sealant or flexible adhesive used to be fairly straightforward. There were fewer products and usually there was somebody to tell you which compound was best for bedding cleats or sealing joints. That’s no longer the case. These days, trying to find the right sealant for the job is as complicated as choosing breakfast cereal, except that if you make the wrong choice you are-literally-stuck with it.

Regardless of what caulk you are using, application is an important component to getting a good seal, and some sealant/adhesives are easier to apply than others. Among the most desirable traits is viscosity; the ideal consistency should be a paste-like material that can be easily injected into a seam or spread on a piece of hardware.

Of the products included in our test of sealants in August of 2010, we found that Sika-flex 291 LOT and 3Ms 4200 Fast Cure had the right consistency to make application a user-friendly experience. They were thin enough to penetrate small seams, but stiff enough to form an even bead. One 3M product, 4000UV, that we initially rated highly for mildew resistance and good ease of application, completely failed after five years — and we weren’t the only ones who experienced this disaster. This type of failure, called a reversion, was more common in the 1990s (we remember it from the 1970s as well), and had since been resolved, according to the American Journal of Architecture’s Continuing Education Center:

“A form of polyurethane sealant failure common in the 1990s is called reversion. In this instance, the polyurethane sealant initially cures and displays normal sealant properties; but after exposure to UV light, the polymer reverts to an uncured sealant state. The material appears to turn into chewing gum in the joint and no longer performs as a flexible sealant.”

When applying sealants, surface prep follows the painter’s mantra of smooth, even, and clean. Any contamination-be it oil, wax, or loose varnish or paint-has the ability to nullify the adhesion of a sealant. The prerequisite to a reliably caulked seam starts with the usual scrape, sand, dust, and wash clean.

Most adhesive sealants like well-prepped gelcoat or an epoxy-primed surface, but in the case of the latter, beware of what’s called amine blush, a residue that forms on the surface of epoxy resins and primers when they cure. Washing the surface before applying an sealant is a simple cure that removes the adhesion-robbing residue.

All products we tested had the near-magic ability to stick to every place they are not welcome, and attention to detail during the application process is required. Lightweight throw-away gloves, a roll of paper towels, and a paper bag to dump contaminated wipe-off towels into are a must. Work from the top down whether its on deck or filling plank seams on the hull. Use masking tape to confine the over-spread and maintain a crisp cut line.

All but silicone sealers can be sanded and painted, but the best bet is to achieve a fair, even bead that needs no hiding. Many companies, including Pettit—who have launched a new line of caulks, offer new UV-resistant and paintable polyether blends that can be used in lieu of silicone, which has a reputation of leaving behind invisible residue that can interfere with the adhesion of subsequent coatings of paint or varnish on the bedded fitting, or even on the adjacent surfaces. If you have to remove silicone or a remove stubbornly adhered polyurethane caulk like 3M 5200, check out our Practical Sailor’s test of adhesive removers. If you are faced with the challenge of removing 3M 5200 or a similarly tenacious polyurethane sealant, we’ve tested several products for removing 3M 5200.

If you’re left with a half-used tube of sealant or caulk, try this preservation method suggested to us years ago by former contributor Dick Wilkens: With a piece of plastic (like Saran Wrap) over your finger, push the sealant back into the tube a bit, leave the plastic in place, and replace the tubes cap. The plastic excludes the air that usually lets the sealant harden under the cap. According to Wilkens, this can extend the usable life of the product for years. Storing opened product in the refrigerator can also extend the caulk’s life. Many home supply stores and hardware stores also sell caulk savers, small plastic screws that fit into the cap.

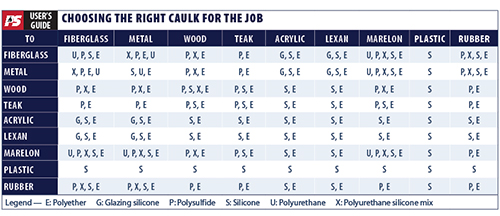

And for those readers who are still standing in the sealant aisle of their local home supply store or chandlery wondering which caulk is best for their project, we’ve carried out a number of tests on caulks and adhesives to help you make the right choice. For more help on selecting an adhesive sealants, subscribers can refer to our January 2018, December 2016, August 2010, April 2005, August 2006 and November 1998 test reports online. If you are sealing hatches or ports, or adding mast or deck hardware, you will also want to read our December 2012 PS Advisor column, which introduces some other options for bedding and sealing, including butyl tape. If you’re fastening hardware to a mast, in addition to a bedding, you’ll also want to use one of Practical Sailor‘s recommended anti-seize compounds for spars. There is also our October 2008 test of caulks for teak decks. Finally, remember to match your caulk with the right type of caulking gun with the right ratio. As explained in our recent caulking gun test, some cheaper guns are not designed to handle some of the higher viscosity caulks.

Once you’ve got your boat hardware well bedded, you’ll want to keep it clean without accelerating the demise of your new seals. Practical Sailor’s Marine Cleaning Guide, a downloadable three-volume ebook, covers every cleaner you’ll ever need—including some inexpensive substitutions that clean better than overpriced brand name cleaners. Not only will you save money and keep your boat looking new, but you’ll support a good cause. When you purchase something from the Practical Sailor bookstore or subscribe to Practical Sailor magazine, you are helping to support our future research in boats, gear, maintenance products, and safety equipment. Thank you for your support.

This is the right caulk for many boats, and I know this from experience. I have tried different caulks to see which one was the best, and the best one is shared here.

Our 2007 Xiamen built 46′ boat suffered from very poor caulking prep and installation during build, then the Sika 291 used exclusively for bedding/sealing suffered revision where exposed to UV.

With time that meant rebedding every window, porthole, most hatches and knifing out/replacing any seal exposed to direct or reflected sunlight.

After much research & discussion during a 2016 refit in San Diego, used 40 + 10 oz. tubes of Silpruf 2000. Initial viscosity, working time, initial set are perfect for most applications. Final strength, shear bond and set elasticity are superior to most marine caulks. (This GE product was only marketed to the construction industry at the time, at 1/3 the cost)

Zero leaks to date on any Silpruf’d bead.

Interesting, we pulled EVERY piece of deck hardware on our 1983 Cal 31 around 2003 and re-bedded them with 4000UV. That includes all stanchions pulpits, hatches, blocks, winches, pad-eyes, and dorades. To this day, not a single hole has leaked a drop. Maybe it has turned to goo again but if it has, it still seals just fine. We know many people who used other products and had leaks a few years later.

The boat is a great way.

Recently, Practical Sailor reviewed sealants, and included my favorite – Life Seal. It is a combination of polysulfide and silicon. It seals, does not fasten like 3M-5200, but does a wonderful job on things like stantions, through hull fittings, handrails, etc. I never tried to paint it, but it is available in a pleasant white color as well as clear. I used it to seal the fittings for our tower which holds our solar panels and dingy.

My best example is our shower and bathtub fixtures at home. When we moved into our new home 30+ years ago, the sealant used by the builder started leaking after six months. I tried several other sealants for around home and boats with no better results. Then I used Life Seal. Now after 30 years, not a leak or any other failure. I did have to reseal the shower door on our whirlpool tub recently, but I blame that more on the kids misusing the door rather than the sealant!

I have been using Dolphinite Bedding Compound for 20 years. I have used it for bedding winches, cleats, and other topsides fixtures which need a waterproof seal but do not need an adhesive seal. It makes it easy to remove the item at some future date. I have never experienced a leak with any fitting bedded with Dolphinite. It is easy to work with and has a very long shelf life. It cost about $60 for a quart can. 5 stars!

For all non-adhesive sealant, and not-bedding, uses aboard our boat, we absolutely love Teak Decking Systems’ SIS-440.

It is by FAR the easiest caulk I’ve ever used, water soluble (for non-cured cleanup), wipes off tools easily, including your fingers, and is easy to cut in if you have to do some repair or replacement later.

We use a 3-radius allway caulk tool (https://allwaytools.com/tool/ct31-3-in-1-caulk-tool-carded/), available at all the places you’d go to for paint or caulk, for right (or similar) angle joints. SIS-440 is specifically formulated to hold against gelcoat, fiberglass, epoxy and teak.

Unless it’s specifically required for an application, I’ll never use a silicone bedding/sealant aboard Flying Pig (a 1978-built Morgan 461 sailboat)…