Maintenance of Interior Teak

For the last decade or so, the majority of all production boats built in the U.S. have been trimmed above and belowdecks with teak. Teak makes abundant sense on deck. With resistance to weathering as its primary virtue, however, teak makes less sense for use as trim below.

Can You-Should You-Build Your Own Fiberglass Tanks?

Due to the litigious environment in today’s society, I feel compelled to advise that fuel tanks used in boats-especially those used to store gasoline or alcohol-based fuels-be built by persons or firms specializing in the manufacture of marine tanks.

Stop That Leak!

Alot of water has gone over the dam since the days when boats were caulked with cotton, and storm windows were snugged up with putty.

Stemming Troublesome Deck Leaks

Deck joints don’t leak as much as they used to. Most builders have switched to less leak-prone types of joints, and most are more conscientious about fastening and sealing them.

Upgrading the C&C 33 Part I

In July 1990 we bought a 1975 C & C 33 to function as a test platform for Practical Sailor. We chose it above others for several reasons: The design seemed typical of many modern sailboats, with a fin keel and spade rudder and moderate displacement; C & C had a good reputation; and the price was right.

Getting the Charge Out of Lightning

Every year, a surprising number of boats are struck by lightning. Almost invariably, there is some damage to the boat or its equipment. The damage can range from minor electrical problems to serious hull damage.

A Rose is a Rose is a Rose, and Wood is Wood is…

For the boat owner customizing his boat, the choice of wood to use in a project can be as interesting as the design or execution of the job. Because of the overwhelming use of teak and mahogany in boatbuilding today, this opportunity to select a different wood is often overlooked.

The Complete Propane Appliance System

Of course, everything on a boat is a compromise, and so it is with propane. It has two nasty traits that must be dealt with: Propane is heavier than air, which allows the gas to collect in the bilge in the event of a leak; and propane is explosive when it collects in such places.

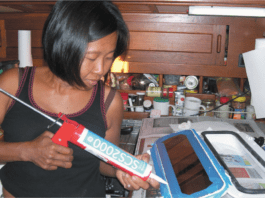

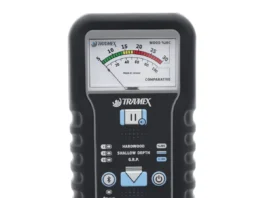

Boat Clinic: Minor Repair to Cored Decks

A fairly common ailment with cored decks is the presence of soft spots where the outer skin has delaminated from the core material. Typically these areas are found around the mast and on the foredeck where heavy-footed spinnaker handlers have trod, but they are candidates to occur anywhere in a relatively large, flat span of unsupported deck.

A Permanent Mount for the Sensibulb LED Reading Light

I have always been a big fan of brass berth lights, but have never really liked the halogen bulbs commonly used in them. The little halogen bulbs run hot, use a lot of power, and are prone to vibrating loose. When Sailor's Solutions (www.sailorsolutions.com) introduced the Sensibulb, I quickly ordered a couple to test in our custom built boat Suzy. They worked so well that I converted all six of our berth lights. The original Sensibulbs were nice units, but the mounting system was iffy. I elected to bypass the mounting system by removing the ceramic bulb holder and directly gluing the bulb support post to the back of the Sensibulb.