Stopping Centerboard Pin Corrosion

Im trying to determine the cause of erosion of the centerboard pivot pin from Arcturus, our 36-foot Soverel keel/centerboard cutter. It is a -inch diameter silicon bronze pin installed new in 2004. I removed the centerboard a few weeks ago and was surprised to see that the pin was heavily corroded. Ive attached a few pictures of the pin. The boat has a fiberglass encapsulated lead keel, with the lead bedded in a resin/sand mixture. The pivot pin fits in a hole drilled through the keel and centerboard trunk (which has encapsulated lead on both sides).

2017 Top Sailing Gear

Each year, just prior to the fall boat show season, Practical Sailor editors consult with our testers to come up with a select list of Gear of the Year from the previous 12 months of testing. For most of the 2016-2017 testing season we focused on essential everyday products that owners of boats of all sizes-with a few exceptions-rely on. While our testers appreciate new technology, they recognize that a safe passage often depends on the reliability of the weakest link, and that weakest link is often a seemingly minor component that gets little attention. In short, our Editors Choice list is not the sexiest product roundup, but if youre serious about keeping your electrical connections corrosion free, making professional repairs on a blue-collar budget, maintaining a safe speed in a steep following sea, or looking for a way to manage a big genoa without upgrading to an electric winch, youll appreciate it.

The Best Respirators for the Boatyard

Athough falling off a ladder or cutting yourself with a sharp tool are the most common boatyard injuries, damage from the foul air we breathe is more insidious. Marine paints contain solvents that can make you dizzy at best or increase cancer risk at worst. Dust from sanding wood is usually only a nuisance, but sanding bottom paint or grinding fiberglass presents serious health risks. Fortunately, theres a wealth of industrial experience with contaminated air…

Esoteric Fibers Call for Epoxy

Theres little debate over the adhesive quality and toughness of epoxy resin-just look at where its being used. We hear about its presence in crucial structures such as aircraft wings, race car bodies and high-end custom racing yachts. But it takes a little familiarity with engineering lingo to help us understand why epoxy trumps its ester relatives.

What’s the Best Anode Material?

Every fall, as the hauled-out boats are sardined into boatyards, a walking tour reveals the casualties from the underwater war. Saildrives are deeply pitted and shedding paint. Bottom paint is burned near seacocks. Folding props no longer fold. Most often, these losses are blamed on the zinc anodes-or lack of them.

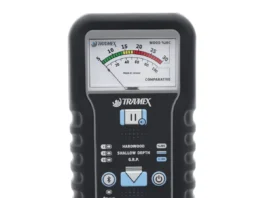

Measuring Anode and Cathode Degradation

The anodes were cleaned, weighed, and installed on 2-foot lengths of 3/4-inch, copper pipe (type M), which were also weighed. We hung the samples between slips in the mid-Chesapeake Bay near Rockhold Creek for one year, cleaning quarterly to mimic light use. At the end of the test period, the samples were cleaned with a plastic scraper and scrub brush, and their interiors were scrubbed with a snugly fitted multi-knotted rope. Testers gave them a light acid cleaning to loosen barnacle residue and scrubbed them again before weighing them. We also measured potential driving force and current for each anode before and after exposure. Salinity at the test site varied from brackish to seawater salty. We will be testing in full-strength salt water for a followup article.

PS Tests Adhesive Removers

Many years ago, one of our editors had an old wooden boat with lovely wooden handrails just inside the companionway that his sailing partner decided could use new varnish. The original coat, which was peeling around the base and worn where hands had gripped it, was sanded smooth and meticulously coated with varnish. Subsequent coats were applied according to the process that had served well for years-varnish, scuff, wipe, varnish, scuff, wipe . . . repeat.

Durabak Nonskid Coating Long-term Test Update

In the January 2012 issue, we evaluated the application ease and traction performance of do-it-yourself nonskid options. A few months prior to the report, a Practical Sailor tester applied the tests Best Choice pick, Durabak, to the coachroof of his Chesapeake Bay-based 1978 Union 36; this served as a real-world test of the coating systems application ease and coating longevity. That field test has reached the five-year mark, so we wanted to offer an update on the coatings long-term performance.

Winch Grease Corrosion Tests

When it comes to most mechanical things-like wheel bearings on a car-its miles that wears em out, as my grandfather used to say. And while there are many reasons why 200,000 miles on a modern car is less remarkable than 75,000 miles was in his day, improvements in lubrication rank high on the list. Lubes of old would oxidize to sludge, stop circulating, wash out, fail to suspend dirt, and drop in pH from acid buildup-or all of these.

Winch Servicing Basics

While using the right winch grease is important, servicing the winch before the grease turns to gum, washes out, or the pawls start to hang up is more important. Makers recommend annual servicing, but racers and full-time cruisers may go one to three years, and weekend sailors might stretch it a bit further. Three years really would be the max, unless you can live with increased wear. If you go any longer, you risk increased wear and even damage. If the pawls hang up and the drum releases, parts can break, and people can get hurt as the handle whips around.