Photos by Drew Frye

Salt and water conspire to reduce our boats, our pride and joys, to pitted and unreliable money pits. Weve investigated corrosion of wiring (see PS July 2010 online), gasoline (see PS August 2012 online), diesel (see PS August 2013 online), and winterizing fluids (see PS September 2014 online), uncovering additives and practices that dramatically reduce deterioration and increase reliability. Engine cooling systems have similar vulnerabilities, and fortunately for us, the automotive engine manufacturers have invested millions in finding those solutions. However, the marketing materials don’t always make the differences clear, and its hard to know which product is the best for your engine.

When divided by cooling-system design, engines are either seawater cooling or closed loop; the latter group is further divided into diesel and gasoline engines. Seawater cooled engines circulate raw sea water in jackets around the engine and pump it out again. There is no heat exchanger. These systems can be winterized like an onboard freshwater system, and you can use ethylene glycol, which should never be used in potable water systems. (For more on winterizing engines, and the differences between ethylene glycol and propylene glycol, see PS August 2014 online.)

Closed-loop systems, on the other hand, are more like the radiator-cooled system on a car, except instead of an air-cooled radiator, a raw-water-cooled heat exchanger carries out the transfer of heat. While the heat exchanger side of the cooling circuit can be managed like a sea-cooled engine, the block side is not winterized each winter, nor is the coolant changed every season. As in the family car, the coolant can last for many years. There is no special reason to choose a marine coolant over a car or truck product, though some are available.

There is one significant difference between marine and automotive gasoline cooling systems. Boats often sit unused for months or years, and because the antifreeze isn’t cooked in operation every few days, the engine can become a breeding ground for micro-organisms that can turn the coolant acidic, rapidly accelerating corrosion. While we will report on this topic in an upcoming article, the summary version is that glycol content must be maintained above 30 percent to prevent bug growth. Additionally, engine coolants are formulated to provide the best corrosion protection when used at 50-percent concentration. Coolant above 50-percent glycol becomes more viscous and less effective at removing heat, increasing chances of local overheating. (See PS September 2014 online for more on measuring glycol levels.)

Diesel engines-particularly those with wet-sleeve liners-add another wrinkle. The thin walls in the sleeve and typical engine clatter combine to create a special condition, unique to diesel engines. The liner begins to ring, and the coolant can cavitate on the power stroke side of the liner, causing accelerated corrosion and can even puncture the sleeve. Marine engines, constantly pushing water and never coasting, endure the sort of high-load use that is known to make engines susceptible.

Unlike automotive formulations, heavy-duty coolants contain additives formulated specifically to prevent cavitation damage. Traditionally, these were sacrificial in nature and were replenished with supplemental coolant additives (SCAs) at every oil change, but now, even heavy-duty coolants are available with permanent formulations; all of the heavy-duty coolants reviewed in this article contain these permanent additive packages.

If you run your engines hard for over 1,000 hours per year-commercial fishing, perhaps-then SCAs should be a part of your maintenance program. If you barely burn a tank of fuel each season, you will be fine replacing the coolant every five years.

A full analysis and performance report for a coolant can be quite involved and expensive (over $15,000), so weve tested only a few critical highlights, just enough to help you understand the differences between classes of products and to avoid a few poor choices. (See How We Tested for details on our test protocol.) Unlike many products, engine coolants are regulated by law and required to meet ASTM International standards (www.astm.org) in many states, Florida and California among them. All of the engine coolants we tested have passed independent testing by the state of Florida.

What We Tested

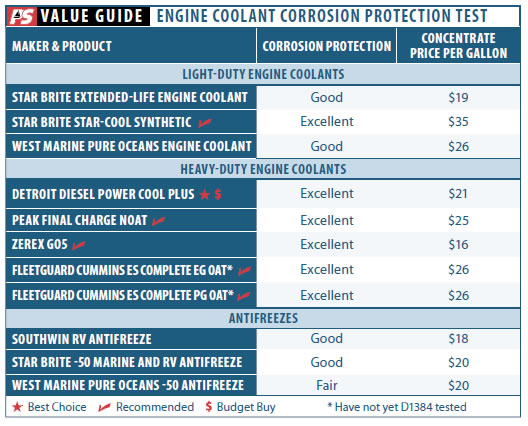

Because a full analysis of every engine coolant on the market would be a massive, impractical project for PS, we decided to run a few simple ASTM tests on a representative group of coolants. We focused on two categories, light-duty coolants for gasoline engines and heavy-duty products for diesels. Comprising familiar marine retail names like Star brite and West Marine, as well as coolants aimed at the automotive and trucking market like Zerex and Cummins, the group was a good cross-section of what is on the market. We also tested a few winterizing agents, not because they are appropriate for use as engine coolants, but because they are appropriate for winterizing sea-cooled engines.

Light-duty coolants

All references to light-duty coolant refer to products suitable for use in gasoline engines and light-duty diesel engines. Similarly, references to heavy-duty coolant indicate that the coolant is formulated for use in wet-sleeve diesel engines. The reference does not imply differences in quality or durability; it is fuel-industry nomenclature reflecting fundamental differences in coolant requirements between gasoline and heavy-duty, wet-sleeve diesel engines.

West marine Pure Oceans Coolant

A propylene glycol-based, light-duty coolant, West Marines Pure Oceans Engine Antifreeze and Coolant performed admirably in our glassware corrosion testing. It allowed very minor cavitation pitting, but it did very well for a light-duty coolant. It met all light-duty corrosion limits, although there was minor aluminum pitting; a concern if you have aluminum cooling system components. Green in color, it is a valid choice if youve got to have propylene glycol.

Bottom line: This product is acceptable for light-duty applications.

Star brite Star-cool Synthetic

A propylene glycol-based, light-duty coolant with a modern inhibitor formulation, Star brites blue High-performance Star-Cool Synthetic Engine Coolant promises long-life in light-duty applications. Like the Pure Oceans, the Star brite Synthetic is a decent choice if youve got to have propylene glycol.

The corrosion protection was very impressive. However, we really can’t justify the price, which is at least twice that of the most premium automotive product: $35 per gallon for concentrated coolant.

Bottom line: We Recommend the Synthetic for light-duty applications.

Star brite Extended-Life

Star brites ethylene glycol-based Extended-life Engine Coolant did well in the cavitation test for an automotive product. Generally, the new organic-acid, long-life products do well in this test, better than the conventional automotive coolants. The coolants glassware corrosion protection test performance was acceptable, but there was minor corrosion of solder and aluminum. We found the concentrate for $18.50 per gallon.

Bottom line: This is a typical automotive product.

Heavy-duty coolants

Heavy-duty products are specifically designed for use in diesel engines. There are a wide range of products in this category, so we looked for those that were readily available in consumer markets or nearly identical in formulation to commonly found products.

The heavy-duty brands are not usually available through home-owner retail sites because, other than boat owners, a home owner has no need of them. Only line-haul trucks and boat engines share the high-load factor (2/3 throttle for long periods) that triggers the need for heavy-duty coolants. That does not mean that they are not good products, and most of the big trucks you see rolling down the highway carry one of the products we tested. They are very common in truck stops and diesel truck-parts stores. Any place that sells diesel engine parts will stock one of the heavy-duty coolants or will know where to get them locally. For owners who run engines hard and are interested in the best possible care, it is worth the effort to get a true diesel coolant.

Zerex GO5

Until very recently, Zerex G05 was the factory fill for both Ford and Daimler/Chrysler. The well-proven product performed predictably well in both our glassware corrosion testing and our cavitation testing. While marketed primarily into light-duty use, the ethylene glycol-based G05 is a nitrite-rich, heavy-duty coolant that is quite suitable for typical sailboat engines.

Glassware corrosion protection was Excellent. This concentrated product is available from most auto parts stores like NAPA for $16 per gallon.

Bottom line: Well proven and widely available, we Recommend Zerex G05 for light- and heavy-duty applications.

Peak Final Charge NOAT

One of many extended-life, heavy-duty products on the market, the ethylene glycol-based Peak Final Charge NOAT (nitrited organic acid technology) is well proven in the field. Unlike light-duty products, it can protect cylinder walls from cavitation erosion, common in heavy-duty diesels. Also available in propylene glycol and glycerin formulations, the Final Charge NOAT was very impressive in all of our corrosion tests.

If you can’t find the NOAT formulation locally-which is not widely available-a similar Peak product, Final Charge Global, would be a worthy option, and its available from Wal-Mart through delivery. The Global meets or exceeds all the specs of the NOAT, and it has had excellent results in cavitation tests.

Bottom line: We Recommended the Peak Final Charge NOAT or Global for heavy-duty applications.

Detroit Diesel Power Cool Plus

A common premium factory-fill coolant for heavy-duty trucks, Power Cool products have been associated with cutting-edge heavy-duty coolants for many years. This NOAT coolant is proven to give eight years, or 500,000 miles, of service in heavy-duty fleets like transit buses and line-haulers-without any additives.

Detroit Diesels Power Cool Plus scored very impressively in all of our corrosion tests. It is available through Detroit Diesel parts dealers as either a concentrate ($20 per gallon) or pre-diluted ($12 per gallon).

Bottom line: We rated Power Cool Plus as the Budget Buy and Best Choice pick among engine coolants.

Others

Two other heavy-duty coolants are worth mentioning, even though we have not yet run the full range of tests on them. Rotella ELC is an ethylene glycol-based product that is very popular with over-the-road truckers. It is specified to last 12,000 hours with one mid-term boost of Rotella ELC extender. Available through truck parts dealers and some chandleries, it sells for $23 per gallon pre-diluted. We have not yet tested it.

Fleetguards ES Complete EG OAT has a loyal following among Cummins engine operators. We tested it for cavitation, but got the sample too late for corrosion testing. It excelled in the cavitation tests. Unusual among heavy-duty coolants, it has been formulated without nitrite, which has been implicated in solder and aluminum corrosion.

In our opinion, its probably the best product available, though you might have to go to a Cummins parts dealer to find it. It costs about $30 gallon for concentrate coolant, and is also available in a propylene-glycol formula. If you want the best heavy-duty coolant, it may be worth tracking down.

Winterizing Agents

Although they are not engine coolants, the trio of winterizing agents we tested-top performers from our winterizing-agent evaluation-performed laudably, passing the minimum corrosion protection requirements of this more difficult test. All are very suitable for winterizing sea-cooled engines, are red to pink concentrates, and are used without dilution. NOTE: We do not recommend these as engines coolants.

Southwins RV Antifreeze -50 is a propylene glycol-based formula with Dowfrost. Dowfrost is perhaps the best known corrosion-inhibiting propylene-glycol-based heat transfer fluid in the U.S.; its ubiquitous in commercial refrigeration and air-conditioning systems. It performed very well both in burst-point testing and corrosion testing.

Star brites -50 Antifreeze Antigel is a premium propylene-glycol product. It provided the best freeze and burst protection among the three winterizing agents. It also performed very well in corrosion testing.

A traditional propylene-glycol product, West Marines Pure Oceans -50 RV and Marine Antifreeze also performed well in burst-point and corrosion testing.

Bottom line: Any of these three, or one of our Recommended antifreeze products (see PS September 2014 online), would be acceptable for winterizing a sea-cooled engine.

Conclusions

Choosing an engine coolant that also protects against corrosion boils down to whether your engine is gasoline or diesel. If you have a gas engine, buy any name-brand engine coolant, and you will be fine. If changing from one product to another, give the system a good rinse. If you have a diesel engine, you are safer with a diesel product, something that is formulated to handle the diesel clatter.

From a performance perspective, Power Cool Plus and Peak Final Charge were both perfect, a tie broken only by retail availability. A few can be found at the local auto parts stores, some at marine outfitters, and truck stops are a sure bet. You must either replace the coolant every 1,000 hours or add a supplemental coolant additive, but given the low hours that most recreational boats get, changing the coolant every five years is a more practical approach.

The winterizing agents we tested were impressive, given that they are not intended to be used as engine coolants. We were surprised. Each of the three is safe for winterizing sea-cooled engines and most anything else. However, these were hand-picked from our prior review of winterizing agents (see PS September 2014 online), and we would NOT expect the same performance from the poor performers in that test.

Always install as a 50-percent glycol mixture, regardless of warm local temperatures, since the corrosion inhibitors are formulated to protect at 50-percent concentration. Forget the marine angle, see your way through the propylene-glycol mythology, and just service the engine according to manufacturer recommendation and the engine category in which it falls. And recycle in the spring, whenever you can. It is that simple.

I referenced this article when choosing coolant for my lightly-used Beta 16 diesel engine. I had some difficulty finding Final Charge NOAT, so I switched to Final Charge Global. I recently removed my thermostat and found thick pink paste. I am wondering if this resulted from mixing Final Charge NOAT and Final Charge Global. I did not mix intentionally, but may not have succeeded in draining all of the old coolant when I removed the tube stack in the heat exchanger for cleaning. Do you know if mixing these two products could result in the pink sludge in my engine?

The formulations are too similar to result in sludge.

Moe likely, oxygen is getting into the system through a small air leak somewhere, resulting in excess iron corrosion. Check the pH of the coolant (if i is lower than 7 that indicates a problem). Also check chloride while you are at it (a seawater leak can also cause this–over 100 ppm suggests a leak).