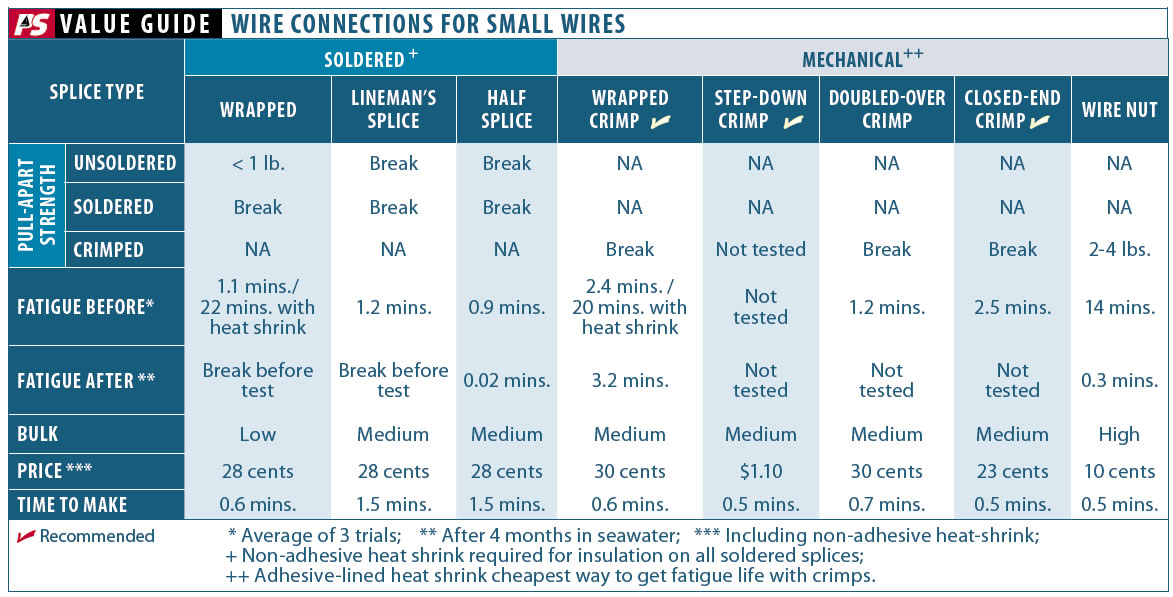

Connecting two standard-size wires is pretty straightforward: Grab a ratchet crimper, adjust it to fit the crimp connector, strip the two wires to fit into the butt connector, slide the wires into the connector and squeeze the crimper. The required materials are readily available: butt connectors for inline splices, ring connectors for terminal blocks and a dab of anti-corrosive grease for the bolts and rings. Done right, these connections can survive some extremely tough conditions. In a test of anti-corrosion greases and connections, we demonstrated how these connections can last up to five years in the worst bilge conditions. In part one of this report on making marine wire connections, we compared several different methods of connection small wires.

But what about connecting the tiny, 22-gauge leads from an LED light, cockpit instrument, or wiring harness from a multifunction display? How do you connect these with 16-gauge wire feeds from the panel? We’re trained not to use wire nuts because they’re hard to seal or to provide with strain relief; they can work loose, damage finely stranded wire, and are forbidden by the American Boat and Yacht Council (ABYC). Although you can use Eurostrips in lieu of a butt-block for smaller wires, theres nothing in the marine catalog or local hardware store for direct connections with small wires. Step-down crimp connectors will work, but these can be hard to find. Soldering can work, but there are concerns about corrosion and fatigue, and both the U.S. Coast Guard and the AYBC don’t approve of connections that use only solder as the sole means of connection. You are free to solder a crimp if you like, but the wire must be physically restrained in case it overheats and melts the solder.

What We Tested

We tested various methods of small-wire connection that are best understood by looking at the accompanying photos. To evaluate soldered connections, we tested the following splices: a common splice formed by twisting the wires together, a lineman’s splice formed by interlocking two twisted loops of wire, and a modified version of the lineman’s splice that we are calling a lineman’s half splice or half splice.

We also tested several crimp methods. The method we settled on for most jobs involved using an oversized butt connector. Because the crimp connectors for 16-gauge wire are actually size 16-14, there is some extra room in a typical butt connector. We slid a butt connector (Gardner Bender model 75-123) up the 22-gauge wire, past the stripped portion of wire, then twisted the 22- and 16-gauge wires together tightly, then slid the butt connector back down over the twisted wires, and crimped. We crimped in the middle and at the end of the butt connector, where the small wire entered. The crimp at the end grabs the insulation on the smaller wire to provide strain relief. This inline connection is fast, easy to seal, and provides some support for the 22-gauge wire. It does, however, depend on there being extra space in the crimp connector for both wires.

A similar method, which we are calling a closed-end crimp, is recommended by Practical Sailor contributor and marine electronics installer Bill Bishop. (See “A Smart Easy Way to Rewire“). This crimp involves laying both wire ends parallel and twisting them together before pushing a butt connector halfway over the twisted ends and crimping. (See photos 5, 6 and 7 in the accompanying Tight Splices for Tiny Wires.)

Observations

When making small-wire connections, be sure to use good-quality tools, including wire cutters, insulation strippers, and ratchet crimpers. Our tester had a cheap combination tool years ago, and eventually threw it in the trash after one too many bad crimps. Also, get good quality crimp connectors; Ancor and Gardner Bender have worked well for us—although the tight center-stop on the Ancor crimps precludes the inline method of crimping. Always twist the strands together before you start, and keep grease off your fingers, if you are soldering. We used Benzomatic lead-free rosin core solder, which is readily available at most hardware stores.

None of the tested connections withstood a great deal of load. A simple twisted splice came apart at less than 1 pound of pull. The wire nut failed at 2 to 4 pounds, depending on the exact manner of the twisting. The lineman’s splice, half splice and crimp connection always broke the wire, although they held as much as 6 pounds.

When we heated the connections to 400 degrees, little changed: The twist splice pulled apart at a few pounds, and the others broke at the wire. The lesson here is that strain relief is essential to any connection using small wires.

Although our test was able to create reproducible failures, the strength of soldered samples can vary greatly according to wire quality. Flexible tin wire is generally preferable to brittle copper-strand wire. In tests, the crimp connector generally finished in the middle of the pack, better than stiff solder jobs, but worse than a sample where the tinning tapered gradually.

The wire nut was a surprise. It consistently held far better than soldered or crimped connections, and nearly as good as heat-shrink protected splices. We observed some damage to strands, but it was minor.

Corrosion was a problem. All of the soldered connections showed considerable galvanic corrosion where the wire met the solder, and all but one soldered sample fell apart when we were blotting them dry to take the after picture. The wire nut also showed considerable corrosion. The spliced connections showed corrosion on the tinned portions but very little on the wire.

Soldered Splices

Although solder is not recommended by the ABYC or the U.S. Coast Guard, we were interested to see whether it improved the durability of our small-wire connections.

Twisted Splice

To create a twisted splice, simply twist one wire around the other. It offers minimal structural integrity, so the connection must be soldered as well. In addition to simplicity, this also gives the smoothest result and is the easiest to make look good.

Bottom line: The twisted splice doesn’t meet Coast Guard or AYBC standards and is subject to corrosion. Its not recommended for damp locations.

Lineman’s Splice

To do a lineman’s splice, you fold the heavier wire in half. Next, you lay the smaller wire in the bend of the larger wire and twist the heavier wire up tightly. Finish by wrapping the smaller wire very tightly and neatly around itself, trimming tight. (See accompanying photos.) This will not come apart, even if the wire melts, meeting the intent if not the letter of the regulation. It is, however, a bit messier to solder and protect with heat-shrink tape, since a heat-shrink tube that will fit the splice might not shrink to the dimensions of the smaller wire.

Bottom line: The lineman’s splice is not acceptable to ABYC, but its the most secure solder-only connection. Its not recommended for damp locations.

Half Splice

To create this splice, strip about 1-inch of the large wire and 2 inches of the smaller wire. Bend the larger wire in half, with the end about a quarter-inch short of touching the insulation. Thread the smaller wire through the bend, and then squeeze the bend flat with pliers. Wrap the smaller wire around the bent large wire, holding it closed. The result is similar to a sheet bend. It is very secure, easy to make, and creates a secure electrical connection, even without solder. Soldering will improve this connection for any permanent use.

Bottom line: The half splice is bulkier than other wire-splices, but it is probably the best method for a temporary connection that uses only tape.

Mechanical Connections

Mechanical connections provide the surest joint, but getting the right fit requires some tinkering with different connector types and sizes. And some connectors are simply not well-suited for the marine environment.

Wire Nut

To use a wire nut, strip about 5/8-inch of insulation off the larger wire and 1 inch off the smaller wire, then twist tightly into a pigtail. Twist the nut firmly in place. Secure the connection with several inches of tape wrapped in the same direction that the nut was twisted.

The fatigue performance of this connection was impressive. It was nearly as durable as soldered splices that were protected by heat shrink. When testers removed the nut, we noticed some damage to small wire strands, but nothing significant. Experts worry about wire nuts coming loose due to vibration and hot/cold cycles; this can happen, but it is rare, and preventable if the nuts are tightly wrapped with tape.

Bottom line: The U.S. Coast Guard allows wire nuts in specific cases (see accompanying USCG Regs and Wire Nuts top right), but the AYBC prohibits their use across the board. For most connections, especially those that might be exposed to water, we think they are a poor practice. In other words, leave these at home, or use them only for quick, temporary fixes when no other alternative is available.

Butt Connectors

The folded crimp, in which we folded one wire back over itself two or three times to increase its diameter, did not perform as well in fatigue testing as a wrapped crimp, in which the smaller wire was wrapped around the larger one before crimping. To make a wrapped crimp, strip about a half-inch from the large wire and 1 inch from the small wire. Slide the crimp a few inches over the smaller wire, twist the wires together, and slide the crimp back over the splice. Crimp as usual.

This only works for wires small enough that you can still slide the twisted pair past the center stop in an AWG size 14-16 crimp fitting. In our experience, an AWG size 16 wire twisted with an AWG size 22 wire can still fit into an AWG size 14-16 crimp made by Gardner Bender, Tyco Electronics, and Ideal-but not Ancor, although these crimps are highly regarded by marine professionals.

In the closed-end crimp, the two wires are laid parallel and pushed into one end of the butt connector for crimping. This approach performed about the same as the wrapped crimp, but they are much harder to seal with heat shrink. A simple way to provide strain relief is to double the crimped connection back over the larger and wire tie it in place. (See photos in Tight Splices for Tiny Wires.) This relieves all of the strain from the connection itself.

We did not test step-down butt connectors, designed to accommodate two different wire sizes. Properly installed with ratchet crimpers, these are another solution, although we would still use heat shrink over the crimp to help provide additional strain relief and improve water resistance.

Bottom line: The wrapped crimp or the parallel crimp are our Best Choice picks for making small-wire connections.

Conclusions

The U.S. Coast Guard and AYBC forbid soldering as the sole means of wire connection because of the risk of separation if overheated. This disqualifies solder-only connections from being among our top picks. We’ve been told fatigue is an issue with soldered connections; perhaps this is true, but we didn’t see that in testing, and certainly not after covering the connection with heat shrink. However, no soldered connection survived seawater exposure without severe corrosion damage. Additionally, since the solder triggered severe galvanic wire corrosion, we do not recommend soldering crimped connectors, even though some favor this as an improved method. In a saltwater environment, it is quite clear that solder actually makes things worse.

Our favorite method for connecting tiny lighting and instrument leads is the wrapped splice that is slid into a butt crimp connector and crimped; its fast, secure, and easy to insulate. Equally good, but not as elegant or easy to seal, is the closed-end crimp. The advantage of the closed-end crimp is that when the butt connector is folded back over the larger wire, then wire-tied and taped, there is no load on the crimp, making it plenty strong for pulling through conduits-albeit a slightly larger diameter.

If you are forced to make a temporary connection without proper tools, the lineman’s half splice is secure and gives a good connection with only tape, but this should only be used for very small loads and should be repaired correctly as soon as possible.

Although the American Boat and Yacht Council (ABYC) wisely recommends not using wire nuts for making electrical connections, the U.S. Coast Guard (USCG) permits them under certain circumstances. According to the USCGs Reg 46 CFR 120.340 cable and wiring requirements: (i) Each pressure-type wire connector and lug must meet UL 486A, Wire Connectors and Soldering Lugs for Use With Copper Conductors, or other standard specified by the commandant. The use of twist-on type wire nuts is permitted when the connections are made within an enclosure, and the insulated cap of the connector is secured to prevent loosening due to vibration. According to the standard, twist-on type connectors may not be used for making joints in cables, facilitating a conductor splice, or extending the length of a circuit.

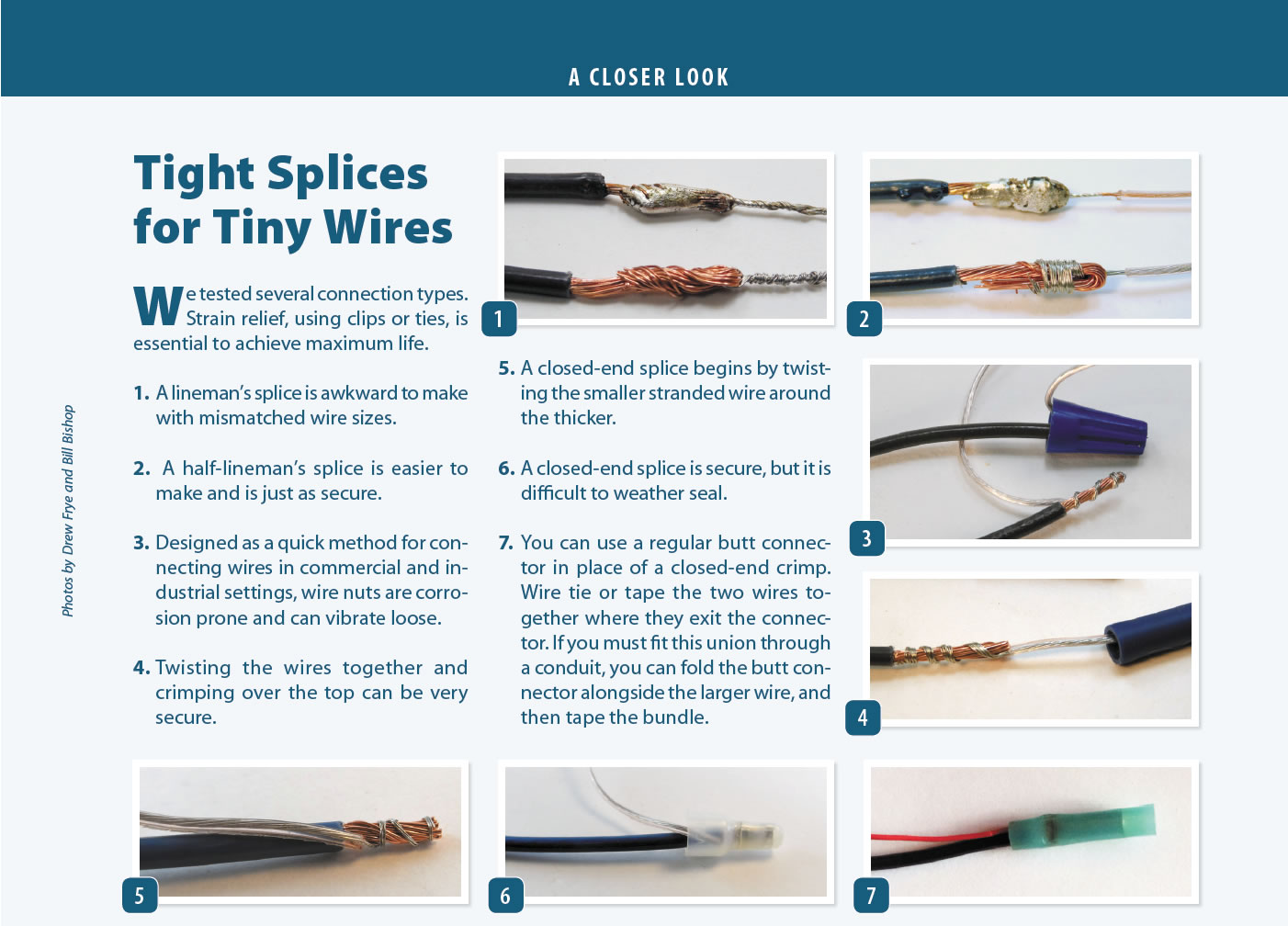

We tested several connection types. Strain relief, using clips or ties, is essential to achieve maximum life.

1. A lineman’s splice is awkward to make with mismatched wire sizes.

2. A half-lineman’s splice is easier to make and is just as secure.

3. Designed as a quick method for connecting wires in commercial and industrial settings, wire nuts are corrosion prone and can vibrate loose.

4. Twisting the wires together and crimping over the top can be very secure.

5. A closed-end splice begins by twisting the smaller stranded wire around the thicker.

6. A closed-end splice is secure, but it is difficult to weather seal.

7. You can use a regular butt connector in place of a closed-end crimp. Wire tie or tape the two wires together where they exit the connector. If you must fit this union through a conduit, you can fold the butt connector alongside the larger wire, and then tape the bundle.

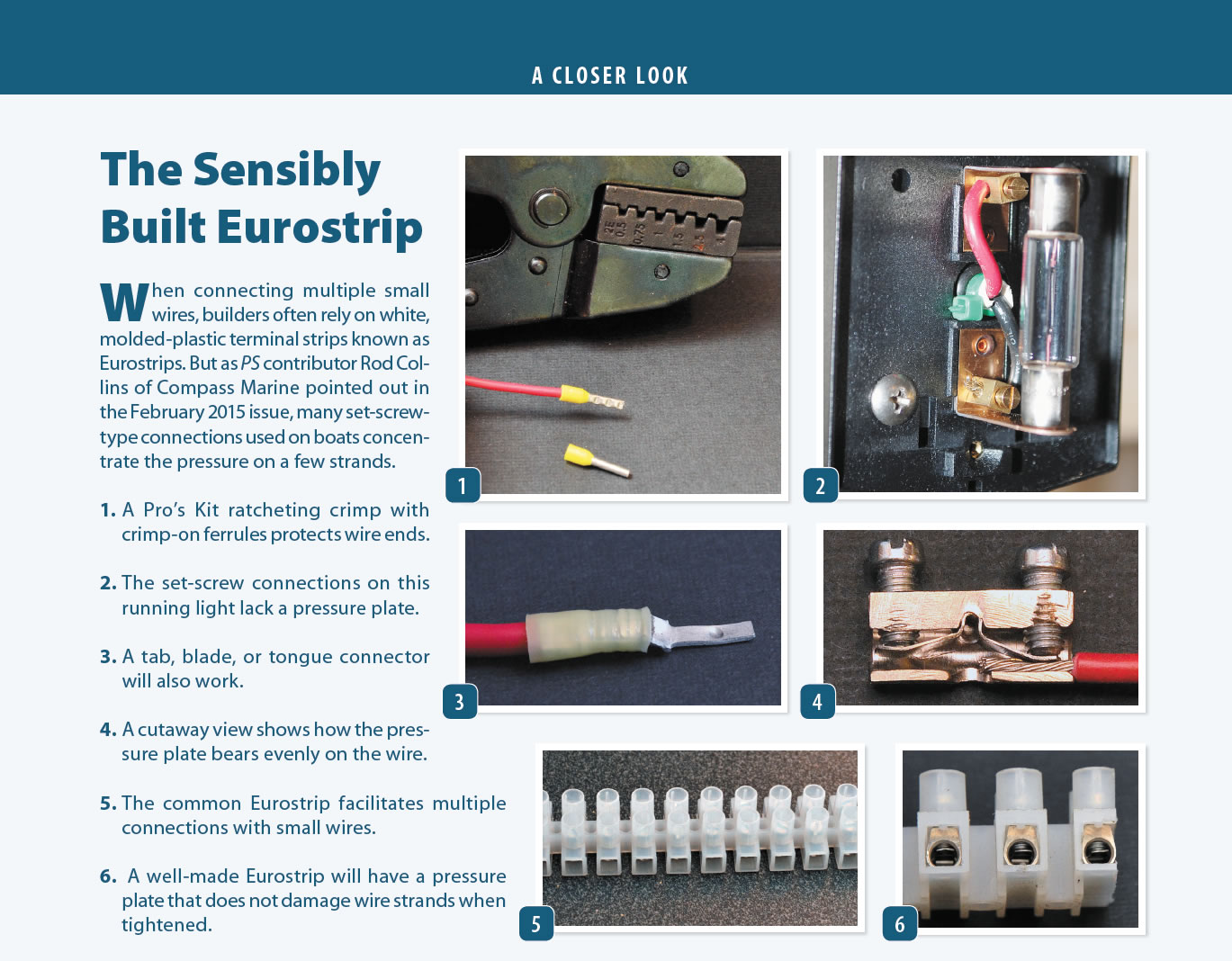

When connecting multiple small wires, builders often rely on white, molded-plastic terminal strips known as Eurostrips. But as PS contributor Rod Collins of Compass Marine points out, many set-screw-type connections used on boats concentrate the pressure on a few strands.

1. A Pro’s Kit ratcheting crimp with crimp-on ferrules protects wire ends.

2. The set-screw connections on this running light lack a pressure plate.

3. A tab, blade, or tongue connector will also work.

4. A cutaway view shows how the pressure plate bears evenly on the wire.

5. The common Eurostrip facilitates multiple connections with small wires.

6. A well-made Eurostrip will have a pressure plate that does not damage wire strands when tightened.

This article was published on 11 November 2016 and has been updated.

Soldering vs. Tinning: In my opinion and by those who manufacture wire cables, Tinning with tin or silver solder enhances corrosion resistance of wire. That combined with electrolytic grease and a proper shrink wrap (the best shrink wrap now comes with a meltable glue to even further seal the joint) will produce a superior joint. I fail to understand the ABYC or the US Coast Guard’s position on soldering. Does a car or a plane in a Florida town experience less salt water exposure to that of a boat? Not really. Plus the added benefit of vibration toughness the tinned joint has is a bonus over a mechanical fasteners. They also can become a source of heat build up if not done correctly. Resistance increases, voltage drops and amps go up. Amps is electrical volume. Not good! The only joint that can be buried inside a wall of a home without access through a switch plate or plug is a soldered joint. It is considered as good as a non spliced wire? No wire should ever be put under a significant tensile load! That’s just poor craftmanship if it is. Wires are not winches meant for pulling. They are meant to conduct electricity.

There is no way that a car or plane that spends its life along the coast even comes close to the amount of salt water that boats are exposed to! For the past 55 years my family has owned a beach house (Long Beach Island,NJ) where the garage is about 30 feet from the lagoon, None of my vehicles or my families vehicles have any rust! The problem with soldered joints is if there is an issue that causes extreme heat those joints will fall apart.

Here is one link I found to help when considering Tinning wires. https://www.cmacable.com/wp-content/uploads/2014/05/when-and-where-to-use-tinning.pdf

Here is a comment from an American Cable Manufacturing Company on the benefits of tinning wire joints. It specifically comments on marine environments. Tinning, today, is considered one of the

best choices for wire that will be exposed to

corrosive or harsh environments, including

marine environments or industrial environments

such as water or pulp treatment operations.

In fact, tinned conductors can extend wire

life by ten times compared to bare wire. Its

affordability makes it extremely cost effective

in nearly any application for which corrosion

resistance and higher operating temperatures

are required.

Crimpers: Anchor does not recommend double crimping for terminals with integral heatshrink and adhesive. I use these terminals wherever possible but with the Ancor single crimp ratchet.

How about Wago connectors

I’ve started using these in non-damp areas and love them. Easy to use, work well with different wire sizes and facilitate 3- or even 5-way connections. Plus easy to take apart and reconnect without damage to the conductor or having to shorten the inevitably already too short wires.

I’d be very interested in what PS thinks of them.

For small wire butt connections it is possible to find ones smaller than the standard 22-18 ga. You can find them on Amazon, 26-24 ga, heat shrink (3:1), (supposedly) “marine grade”. Search with “vamrone” in your search string. I have been using them and they work well, although I haven’t subjected them to the rigorous tests the PS does.

I have had good luck with quality Euro or DIN connectors with pressure plates. You will need a suitable screwdriver.

I fill the cavities on the DIN strip with dielectric (bulb) grease. The connection point before inserting the wire and the screw after the connection is complete.

I bought my connector strips off Amazon. I had to look carefully at the product images to make sure that the one I bought had a pressure plate. Most don’t. The product description usually don’t mention the essential pressure plate.

DINs allow multiple wire sizes by design. They also allow easy equipment replacement as the connection is reusable.

I can see why testing did not include dielectric grease since the point was not to test it, but can we assume that it’s use in any connection is valuable to prevent corrosion? I use it under regular heat shrink when sealed heat shrink connectors are not available and before crimping, hope that’s not a bad thing for some mysterious reason.

If you must solder – use the practice which comer from MIL-std soldering:

You will need:

Soldering tin with flux core – get some MIL-spec as the specs are very specific about the flux so you can end up (after the proper cleaning of the solder/wires) with a flux-free result. Any leftover flux becomes corrosive if/when moisture enters the equation.

Isopropanol and a couple of small bristle brushes for cleaning off flux.

A temperature controlled soldering iron set to the temperature spec’ed on the soldering tin (Yes – they vary depending on the composition)

Heat sinks that fit the wire gauge of the various wires in question. Prefer this style: https://www.micromark.com/Heat-Sink-Soldering-Tweezer

Flexible coating to keep moisture out

Flat-braided waxed “Sewing” twine or zip ties for strain relief

Strip off whatever length of the insulation casing you need. Ensure the strands are laying in their original twist and adjust if needed. Place heat sink on the wire core a few mm from the insulation. tin/re-tin the wire end. This is done to avoid ANY solder/flux from wicking into the wire under the insulation layer. Clean off the wire with isopropanol to remove ALL leftover flux. Do whatever twisting, interlocking bend you want to use – the tinning helps protect the strands from breaking in that process – but avoid sharp bends – minimum bend radius should be at least the diameter of the wire used. Re-attach heat sinks to both wires like when tinning the wires. Solder the wires with enough tin to fill all voids but not more than you can still distinguish the wire strands underneath. Once cooled; wash off all flux with isopropanol. This is absolutely crucial or the connection will corrode relatively quickly as the flux+moisture is quite corrosive. Inspect the solder surface – it needs to be a mirror finish without any pits. A matte finish indicates that the solder was disturbed when it solidified by movement or excessive air movement – in this case – redo the soldering. You can use wicking braid to “suck up” excessive solder before going again. A grainy soldering joint is mechanically weak and prone to corrosion.

Coat with flexible varnish (there are MIL spec products available for this purpose) or the Star-Brite liquid insulation coating (in a pinch). Use flat-braided waxed cable “sewing” twine or zip-ties to create strain relief to ensure the connection doesn’t see any pull (tin can “cold-float over time if pulled with even small loads).

I have done a number of these kind of connections on boats – even sportboats which invariably will end up with water inside the boat on a regular basis and have them hold up just fine. A bit tedious but it works.

I’ve come around to using wire nuts 4 bilge pump and float switch connections, with Dielectric grease to seal. This makes diagnosing a non-functioning pump and replacing it if necessary a very quick job. Naturally you get your connections above any normal high water level.

Non-insulated butt connectors are useful since the connection can be visually inspected to be sure the connector has annealed into the wire. Then add shrink-wrap tubing (fed over the wire in advance, of course.)

I found that if I cut the shrink tube off of 1/2 of a red butt connector, it fits up inside a yellow butt connector. Crimp the little wire into the red connector, the big wire in the yellow, and crimp the end of the red connector into the yellow. Shrink everything and it seems legit.