Cruising gives you the freedom to go to both popular places and remote, out-of-the-way locations. If you have scuba equipment on your boat, the underwater world is open to exploration. Since we have to take our breathing gas, one limiting factor is having cylinders filled with air or nitrox for our next excursion. If you are cruising in a popular location where diving is one of the everyday activities, like the U.S. Virgin Islands or the British Virgin Islands, chances are a dive operation is nearby. You can take your cylinders to the dive store and have them filled.

But, if you are cruising the remote islands of the Bahamas, Grenada or South Pacific, you will need to find a way to refill your cylinders. You can carry extra cylinders, which will delay the need for refills, but eventually, you will need to return to a location with a dive store, or you will need to fill your cylinders aboard your boat.

Pros and Cons of Having Your Own Compressor

Installing a dive compressor on your boat comes with a significant upside. Primarily, it allows you to refill your cylinders wherever you are located so you can continue diving and exploring. Since we can also use scuba equipment to maintain the boat, it will help you keep up with some of your boat chores, like cleaning the bottom periodically or doing underwater repairs.

But there are some disadvantages too. A dive compressor is another system on your boat that must be maintained. Additionally, you must keep specialized oil, filters, spare hoses, etc., on board for routine maintenance. And, depending on the power you choose, you’ll need additional parts for the drive motor or engine.

Choosing a Dive Compressor

If you decide to add a compressor to your boat, you need to consider several things, including the drive source, the size of the unit and filtration.

Size

In general, the larger the unit, the faster it will refill your cylinders. But, when onboard space is a premium, you must consider how much space you are willing to allocate to your compressor. Additionally, the larger the unit, the more drive power it requires. So, a function of the size you want to install is the power source and the energy needed to run it.

Drive Engine or Motor

The first thing to consider is how you will drive your compressor. When I first started helping cruisers decide to add systems to their boats, there was little choice but to put a gasoline engine on a frame with the compressor. While this is still the best option for many cruisers, other options are available.

Electric Options

With the explosion of catamarans, lithium batteries, generators and large solar installations, an electric drive motor has become a viable option. An electric motor requires less maintenance than its gasoline alternative and makes filling cylinders quicker to set up. The actual draw of the motor is manageable, but you need to remember that small compressors are not fast and that the draw may continue for twenty to forty minutes or more. Pulling off the lithium house bank may not be an option without adding a generator or solar to supply more power.

For example, an electric motor drawing 16 amps attached to a 3.5 cfm compressor will require 3,520 watts of power and need to run 23 minutes to fill an aluminum 80 cubic foot cylinder. Filling one cylinder will require about 120 amps of battery/solar/generator.

Electric motors, especially 110 to 120 volt motors, pull more amps to start the motor before settling into their running draw. This initial draw may trigger safety circuits in your inverter. One solution to dealing with this initial draw is the installation of a soft start, which feathers the motor from its initial start to its full running draw. Soft start circuits are readily available but add to the cost of your compressor system. They are size-dependent. For most smaller units, the price is about $800 to $900.

Parts Availability

Like anything, many units are available, including some lower-cost compressors made in China. While some of these lower-cost alternatives reduce your initial cash outlay, finding repair parts or qualified service providers may prove difficult. As you move further away from the more populated areas, the lack of parts becomes more pronounced. Finding a Bauer part in Micronesia might be difficult, but finding a part for a lesser-known brand may prove impossible.

During your evaluation period, talk to the distributor or the manufacturer to determine their worldwide parts distribution network. Do they have a dealer or distributor in the areas you plan to visit? Or do they have the ability to ship parts to your location from their local warehouse? This may mean you can keep using your compressor on your trip rather than having an expensive piece of non-functioning equipment deteriorating on your boat.

Using our Bauer Compressor example again, they have operations in Asia, Australia, Austria, China, Egypt, France, Germany, India, Italy, Japan, the Middle East, Korea, Spain, the United Kingdom, and the United States. Each of these units ships to countries in their region, so if you are in Tonga, you could get your parts shipped from Australia, which is closer than having them shipped from the central warehouse in Germany.

Installation

Part of your decision in selecting a compressor for your boat is where you will put it. While these units are small compared to the compressors used in dive facilities, they may still be large, cumbersome and heavy.

Permanent Locations

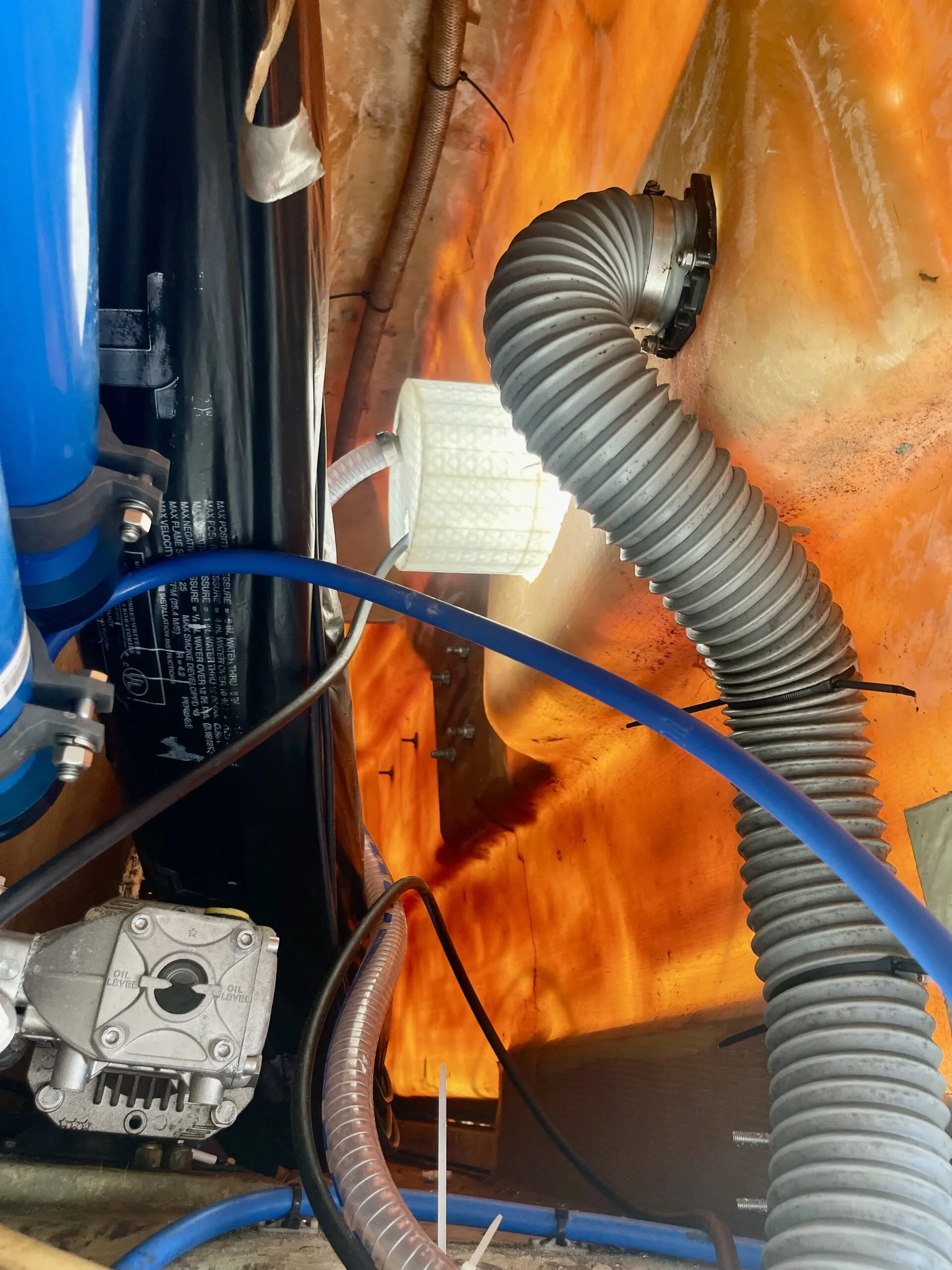

If you have decided an electric motor is the correct unit, an ideal location may be in your engine or generator compartment, assuming you have enough room. This location keeps the unit out of the way and out of the weather. Iain and Brioni chose this on Indiko. They mounted their Coltri Icon in one of their engine bays and routed the fill hoses and air intake to their transom. Another popular storage location is in a cockpit locker, making it convenient to fill cylinders. Brown and Eileen Councill, @sailingblownaway, chose to mount their Bavaria Fun2 electric compressor in this location.

Permanent installations require more thought than temporary locations. Electrical connections must be secure and water-tight, and the drains and filter must be accessible, as does the condensate water drain reservoir. You also need access to the oil reservoir sight glass or dipstick and the oil filler cap. Your fresh air intake must avoid contaminants like oil, chemicals and exhaust fumes. Many people have an air intake “snorkel” deployed when filling cylinders.

Cooling the unit is essential as well. As the temperature rises, the air moving through the cylinders and cooling loop produces more moisture in the form of condensation. This water is vented through a line from the cylinders and the air output. There is an in-line water trap, but with the increase in moisture, more water may pass through the trap and on to the filter system. Since the filter media reacts more quickly with moisture than oil, the media will have a shorter lifespan and, if not checked regularly, may allow oil to pass through the filter and into your scuba cylinder.

Temporary Storage

A temporary storage location may be more desirable for electric and gasoline-driven compressors. Depending on the boat, a cockpit locker with a shelf for the unit or a locker below may work as a storage location. Remember that while these units are smaller than the compressors used by dive shops, they are still heavy and may be challenging to move up on deck when you want to fill cylinders. For this reason, some sailors store the units in dedicated deck boxes.

Gary and Brooke from @Sailingonelife keep their gasoline engine-driven compressor in a deck box on the aft deck of their 1984 Nautical Development Offshore 40. In contrast, Mads on @saillife keeps his electric compressor stored below and moves it when he wants to refill his cylinders.

Ease of Use

Part of your location decision should take into account the actual filling. Depending on the size of your compressor, it may take thirty minutes or more to fill each cylinder. Since most boats move and rock at anchor, you must secure the cylinder while filling it.

The Councills’ cylinders are stored in custom stern rail mounts, so they place their used cylinders back into the rack and use a long fill hose from the compressor to their cylinders. The designers at Kraken Yachts say, “Ideally, the yacht will have a dive compressor, which should be housed in the stern lazarette as you don’t want to move the dive tanks around the yacht deck too much.”

You can use long hoses to reach your cylinders, but remember you will need to monitor the fills and the compressor, so making it easy to do both will lead to more relaxed diving.

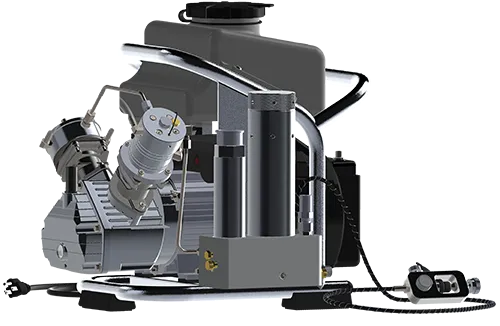

Choices

As I mentioned earlier, there are a number of choices. The following table outlines some of the more popular compressor systems.

Small Diving Compressor Comparison

Compressor Model Mantus Coltri Icon LSE 50 Bavaria Fun 2 Coltri Icon LSE 100 Bauer PE 100 (Poseidon) Nardi Atlantic LW 100 E1 Bauer Junior 2 Bauer Oceanus

Manufacturer Mantus Marine Aerotecnica Coltri S.p.A. IDE-Kompresors eK Aerotecnica Coltri S.p.A. Bauer Kompressoren Gbh Nardi Cpmpressori SRL Lenhardt & Wagner Bauer Kompressoren Gbh Bauer Kompressoren Gbh

Manufacturing USA Italy Germany Italy Germany, USA, China Italy Germany Germany, USA, China Germany, USA, China

Weight 31 kg (69 lb) 30 kg (66 lb) 48 kg (106 lb) 37 kg (82 lb) 44 kg (97 lb) 46 kg (101 lb) 43 kg (95 lb) 45 kg (99 lb) 47 kg (104 lb)

Dimensions W x D x H 380 mm x 480 mm x 500 mm 610 mm x 37 mm x 390 mm 710 mm x 410 mm x 400 mm 780 x 320 x 350 mm 740 x 340 x 420 mm 800 mm x 408 mm x 400 mm 780 x 380 x 400 mm 780 x 340 x 420 mm 790 x 410 x 420 mm

15 in x 19 in x 20 in 24 in x 14.5 in x 15.3 in 28 in x 16 in x 16 in 31 in x 12.5 in x 14 in 29 in x 13 in x 16 in 31 in x 16 in x 16 in 31 in x 15 in x 16 in 31 in x 13 in x 16 in 31 in x 16 in x 17 in

Fill Rate 35 lpm (1.2 cuft/min) 50 l/min (1.8 cft/min) 110 l/min (3.9 cuft/mib) 100 l/min (3.5 cft/min) 100 l/min (3.5 cft/min) 110 l/min (3.9 cuft/mib) 100 l/min (3.5 cft/min) 82-110 l/min (2.9-3.9 cuft/min) 140 l/min (4.9 cuft/min)

Lubrication type splash oil splash oil splash oil splash oil splash oil splash oil splash oil splash oil low-pressure lubrication

Oil capacity 14 oz 0.3 l 10 l 0.3 l 0.36 l 10 l 0.5 l 0.36 l 1.3 l

Dive motor Engine/Gas No No Honda GP200 4.3 kw Honda GP200 4.3 kw SUBARU 4.2 kw SUBARU 4.2 kw/Yanmar Diesel Honda 4.1 kw SUBARU 4.2 kw SUBARU 5.3 kw

Drive Motor Electric 110V Single Phase 110V Single Phase 115V/220V Single Phase 115V/220V Single Phase 220V Single Phase 115V/220V Single Phase 115V/220V Single Phase 115V/220V Single Phase 220V Single Phase

Time to Fill one empty AL80 (minutes) 67 46 21 23 23 21 23 28 - 21 16

Marine Preparation marinized (all components made to survive in the marine environment) Marine Package: rust proofing, stainless steel fram fittings and brackets Marine Package: painted compressor block and the stainless steel frame. Yacht Package: NEMA - 4 electrical box, Motor starter, Automatic condensate drain with muffler/separator

and condensate reservoir, Pressure switch, Filter Housing, Stainless steel fittingsYacht Package: NEMA - 4 electrical box, Motor starter, Automatic condensate drain with muffler/separator

and condensate reservoir, Pressure switch, Filter Housing, Stainless steel fittings

Filtration System Mantus Triplex Air Filter: MM-249 Coltri Filtration System Bauer P11 Filtration System Coltri Filtration System Bauer P11 Filtration System NARDI AT141 Filtration System Bauer P11 Filtration System Bauer P11 Filtration System Bauer P11 Filtration System

Approximate Cost (USD) $2,550 $2,175 $3,100 (Marine Electric) $3,995 $4,175 $5,189 (electric) $5,999 $16,901 w/ Yachting Package $17,945 w/ Yachting Package

Operation

Like any system on your boat, you must take a few steps before starting your compressor and refilling your cylinders. In his self-titled manual “Compressors for Dummies,” Jess Stark from Stark Industries has the following general guidelines for compressor operations:

- Read the service manual—again and again.

- Check the logbook for the present condition of the compressor.

- Check the lube level and the appearance of the lubricant.

- Check the status of purification before filling tanks.

- Check compressor condition for cleanliness.

- Check for oil leaks.

- Keep compressor and especially intercooler fins clean.

- Always check for air leaks.

- Monitor fill rates and investigate air leaks if the rate slows.

This list is an overview of the compressor’s operation. In his book, Jess has other things you should do when operating the compressor (to access the manual, contact Stark Industries via their website).

Clean Air

One of the more important points is to help make sure the air coming into the compressor is as clean as possible. In other words, don’t start the compressor if there are exhaust fumes, smoke (cigarette, fires, etc.), paint smells, or other contaminants in or around the compressor air intake. And keep the air intake filter clean. On many boats, the air intake is attached to a “snorkel,” hoisted above deck level to help ensure the unit gets cool, cleaner air. The manufacturers usually have guidelines on the snorkel’s maximum length and the tubing size required.

Condensate Trap

Another point often overlooked is the importance of starting the compressor with the condensate water trap open, and when you are finished filling, open the trap and let the compressor run for about five minutes to help ensure that as much of the condensate is expelled as possible. Remember, this water is usually mixed with some oil, so you don’t want to dump it in your bilge.

Because the air coming out of the compressor contains some hydrocarbons, water and other contaminants, it is passed through a filter. Commercial pre-packaged filters contain primarily molecular sieve and activated charcoal. It may also contain a small amount of Hopcalite, a catalyst that converts carbon monoxide to carbon dioxide. Some of these filters also include an indicator strip to help you determine the status of the filter. Keep track of the number of cylinders you fill on each cartridge, and make it a practice to check this indicator and compare it to your filling notes before filling your cylinders.

Boat Stability

One other thing to consider is the stability of the boat when filling. Many manufacturers state that the maximum allowable inclination for operating the units is five degrees. Exceeding this level and the oil may not adequately cover all of the operating surfaces, thereby shortening the life of some components.

Maintenance

Checking the oil level and the appearance of the oil is the first step in maintaining your new compressor system. The oil should be clear and filled to the appropriate level. The manufacturer has a recommended oil change schedule. The Bauer PE100-T Poseidon compressor manual states that synthetic oil should be changed every 2,000 hours or biannually. Coltri-Sub recommends changing the oil every 50 hours or annually, while L&W recommends changing the oil every 500 hours after the break-in period or at least annually.

One of the most neglected maintenance items is actually running the compressor. According to Jess Stark, the compressor should be run weekly to reduce damage to the unit’s internal components. So, even if you are not diving, ideally, you need to run your compressor for twenty minutes each week.

Checking your air intake filter and the filter on the outflow side of the compressor is also essential. Replace them as needed.

Most of the manufacturers recommend checking all of the fittings for leakage regularly. Using a little soapy water on the fittings, you can quickly identify any loose fittings resulting in a compressed air loss. This check should also extend to your fill hoses and gauges.

When not in use, fill hoses, and the snorkel should be curled up and stored so they do not have things piled on top of them. The intake filter and fill ends should be covered to keep them clean. Installing high-pressure, stainless, quick disconnect fittings from companies like Swagelok or Parker will make storage easier.

Do You Need It?

One thing that bears repeating. Ask yourself how much diving do you plan on doing and how long you will be away from dive centers. Andrew Trent from Reload and Charge pointed out, “Many compressors depart on voyages with good intentions, but sadly, used gear outlets along the Southeast U.S. coast offer rusted and trashed compressors for a dime on the dollar on their return or vessel sale.”

The Bahamas and the Caribbean are vacation and dive locations, so airfills are widely available. The Councills, @Sailingblownaway, also noted that airfills are available at many French Polynesian islands.

If your plans include spending much time on remote atolls hundreds of miles from population centers, then a small compressor is a good fit. It depends on your sailing plans.

Conclusion

Choosing the best unit for your boat involves researching where you will put it and how often you plan on using it. The added freedom a scuba compressor affords you comes with some new responsibilities. You need to use it regularly, which isn’t a bad thing. You also have a new system to add to your maintenance schedule. This system requires more spare parts, including filters and specialized oil.

The compressor on your boat allows you to explore the world around your boat, even in the most remote areas. Having unlimited air makes your visits underwater easier and more frequent, and having cylinders also aids in underwater repairs and maintenance.