A Do-It-Yourself Winter Cover Frame

Why is it that folks who tuck their dogs into fancy hand-knit sweaters seem to be the same ones who leave their boats unprotected through northern winters? Snow, ice, air pollution, and sunlight, combined with alternating periods of freezing and thawing, can age a boat must faster in the winter months than in the more moderate climate of summer.

Practical Sailor’s 2011 Gear of the Year Picks

Each year, as the fall boat shows—and the deals that come with them—appear on the horizon, we pore over the numerous products we’ve reviewed in the previous 12 months to select the cream of the crop for our Editor’s Choice awards. We hope the list will help readers better navigate any boat-show or end-of-season shopping. This year, we picked from the Best Choice products evaluated in the September 2010 through August 2011 issues. The 2011 GOTY roster includes an electric outboard, some stout bullet blocks, electric marine toilets, bilge pumps, chafe gear, and marine maintenance products like bottom paint.

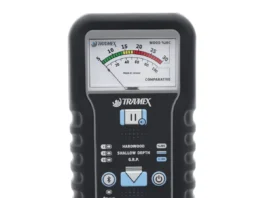

Maintenance All-Stars

With the gazillion marine maintenance products out there, it’s an annual challenge to narrow the field down to just a few superior products for our Gear of the Year (GOTY) list. This year, our top maintenance picks came out of our endless antifouling-paint testing and our performance evaluation of multi-purpose cleaners—products we suspect most of you buy and use regularly.

The Best Marine Varnish: Exterior Wood Finish Tests

Testers applied dozens of exterior wood finishes (22 one-part varnishes, six two-part varnishes, 18 synthetics and satins/varnish alternatives, and eight teak oils and sealers) to small panels of bare solid teak and set them out to face the rigors of South Florida's weather. Two years later, our search continues for the ideal wood finish-relatively easy to apply, easy to maintain, lasts multiple seasons, and is affordable. Given that most wood coatings are rarely expected to last longer than two years in the marine environment-particularly in super-sunny locales-its no surprise that weve seen more significant changes in the coatings in the last six months than we had in previous checkups. With the exception of a few two-part products, the test coatings had lost their sparkle at the two-year mark, ratings slipped across the board, and weve come to accept that perhaps theres no Holy Grail of exterior wood finishes.

Whey Overdue for a Recoat

Practical Sailor often supplements panel testing with product challenges aboard our test boats to see whether top products still earn their keep in the real world and to try out new products. Two such evaluations are our exterior wood finish tests. In the January 2011 issue, we introduced a head-to-head matchup of varnish alternatives—market-newcomer PolyWhey from Vermont Natural Coatings versus perennial favorite Interlux’s Sikkens Cetol Natural Teak—that had been applied to our Cape Dory 25 test boat. For that test, we’ve just let nature run its course: no band-aid touchups, no maintenance coats, no freshwater rinses, no TLC at all.

Mailport: September 2011

Letters to Practical Sailor, September 2011. This month's letters cover subjects such as: Shoes for Crews, Washing Dock Lines, and More!

Where Credit is Due: September 2011

Letters to Practical Sailor, September 2011. This month's letters cover subjects such as: Johnson Pumps, Raymarine, Edson and More!

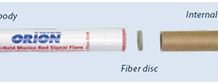

Orion Reports on Defective Flare Investigation

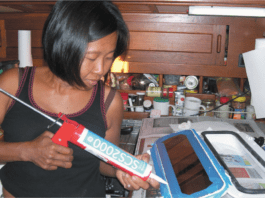

In the July 2011 Mailport, Practical Sailor reported that a new Orion handheld flare had malfunctioned during an emergency training course at the Annapolis School of Seamanship. The defective flare had melted through its end cap, allowing hot, melted slag to drip out.

Local Loft Versus Web-based Service

Not every sailor has a selection of local sailmakers to choose from. He or she must instead rely on Internet research and phone conversations to find the best sail for the best price. As most of the world’s sail production takes place in a handful of high-volume production lofts abroad (China, Sri Lanka, and Africa), U.S. sailmakers have taken on the role of sail designers—rather than sailmakers.

Sailmaker Survey Reveals Readers’ Favorites

Our informal online sailmaker poll generated 336 complete responses, not large enough to be statistically significant, but still useful, in our opinion. In total, readers recommended more than 100 different lofts. The responses are subjective to each respondent’s experience, making it impossible to fairly rank sailmakers based on the poll, so readers should consider this report an overview and use it accordingly in any sailmaker search. The responses can offer some insight into what can be expected of a specific sailmaker and what should be considered in the selection process.