Plumbing – Tip #2

While permeation of waste gases through flexible sanitation hose is a major source of odors in the head, it is not the only one. Here are some tips to help you target odor control:

Hose

We believe that replacing flexible white PVC sanitation hose with Shields Poly-X or SeaLand OdorSafe Plus hose will help eliminate odors. But it, too, will eventually fail, albeit after a much longer time. You can prolong the lifespan of sanitation hose by eliminating low spots in the installation where sewage collects. No sewage sitting in the hose, no hose failure. Hence, vigorous flushing of the hose helps, too. This is fine if youre offshore and pumping directly overboard, but if youre pumping into a holding tank, over-flushing also fills the holding tank faster.

Rigid PVC

Our tests have proven what we already knew, that rigid PVC pipe contains odors. When re-plumbing the head aboard our 1975 Tartan 44 test boat some years ago, we used rigid PVC as much as possible between the holding tank and discharge pump and seacock. Of course, you can't connect rigid PVC directly to them, so need to switch to flexible hose, using adapters. This also helps protect the rigid PVC from cracking should it be exposed to forces when the boat is crashing around or twisting slightly.

Freshwater Flush

Not all head odors emanate from sewage; in fact, considerable malodors arise from the toilet bowl itself: rotting organic matter such as seaweed and krill. Some toilets use freshwater rather than seawater for flushing. While this may not be practical for the bluewater cruiser, on other boats it may make a lot of sense.

We used a VacuFlush toilet for several years and found it only required several pints of water per flush; when the freshwater tank could be refilled at a nearby dock, wasting potable water on toilet flushing wasnt a big deal.

Peggy Hall, author of Get Rid of Boat Odors: A Boat Owners Guide to Marine Sanitation Systems and Other Sources of Aggravation and Odor, is well-known for her expertise in marine sanitation. Hall recommends shutting the seacock when leaving the boat, pumping the bowl dry, and then pouring a quart of fresh water into the bowl and pumping that through the system. She says, …this routine when leaving the boat will solve most odor problems.

For additional advice on ways to setup and maintain a healthy sanitation system, purchase and download the Practical Sailor ebook, Holding Tanks, Plumbing, and Odor Control today.

Plumbing – Tip #3

While permeation of waste gases through flexible sanitation hose is a major source of odors in the head, it is not the only one. Here are some tips to help you target odor control:

Inline Deodorizers

There are a number of inline chemical dispensers that treat the seawater between the intake seacock and toilet pump. A crude metering device allows a small amount of a blue tablet to dissolve into the flush water-sort of like the giant in your toilet bowl. The chemicals are supposed to be nontoxic, biodegradable and not harmful to the environment. These disinfectant/deodorizers also seem effective.

Holding Tank Treatments

There are innumerable tank additives-chemicals, bacteria and enzymes-formulated to deal with holding tank odors. Some simply mask it, others break down and emulsify solids.

In tests, weve found Yara Chemicals Odorlos, Camcos Advanced Enzyme Formula, and Thetfords Eco-Smart to be effective.

Waste contains aerobic (needs oxygen to survive) and anaerobic (lives without oxygen) bacteria, and only the latter is malodorous. If the waste is well ventilated with fresh air, the aerobic bacteria will overcome the anaerobic bacteria and the holding tank wont smell. A 5/8 or 3/4 vent hose no more than 3-feet long and without sharp bends will help. Off-the-shelf vent filters weve found to be effective are the Big Orange 5/8-inch and the Sealand SaniGard 5/8-inch.

Maintenance

Everything gets old and deteriorates over time. But with regular, proper maintenance of the sanitation system, you can keep the head odor-free. Some good rules of thumb:

- Rebuild the toilet pump periodically.

- Empty and rinse the holding tank and hoses with fresh water, and replace hoses you suspect are permeated with malodor.

- One way to identify failed hose is to rub a clean cloth over it and sniff it every foot. Subjective sensory tests-a technique more formally known as organoleptic testing-do not, in general, produce quantitative results. And, of course, when it comes to identifying specific sources of sewage aroma, its not easy to find willing noses (a phenomenon thats been described as recalcitrant organolepsis). Your crew, of course, will not hesitate to notify you of any general malodors in the cabin, nor will they hesitate to demand that you do something about it.

For additional advice on ways to setup and maintain a healthy sanitation system, purchase and download the Practical Sailor ebook, Plumbing and Odor Control.

Rafting Up – Tip #1

From Bob Bonds The Handbook of Sailing

Rafting up is the term given to berthing alongside another boat (or boats), whether next to piles, a pier, a float or a mooring. It is not an ideal way of berthing because if a boat on the inside of a raft wishes to leave first it causes considerable inconvenience. Another disadvantage to rafting up is that the crews of the boats in the raft will have to cross other boats to get to and from the shore.

In a crowded harbor, however there is often no choice. There are certain precautions you should take before rafting up. Try and find out if the harbor limits the number of boats in a raft. If there is someone on board the boat you are rafting up to, ask permission first. You need to make sure that your lines are long enough to secure your bow and stern to the permanent fixing- float, pier, or whatever- if you find yourself either in tidal waters or on the outside of a raft of several boats. Try and avoid a raft where only the inside boat is secured to the pier or piles- such a raft will swing backwards and forwards making your stay uncomfortable.

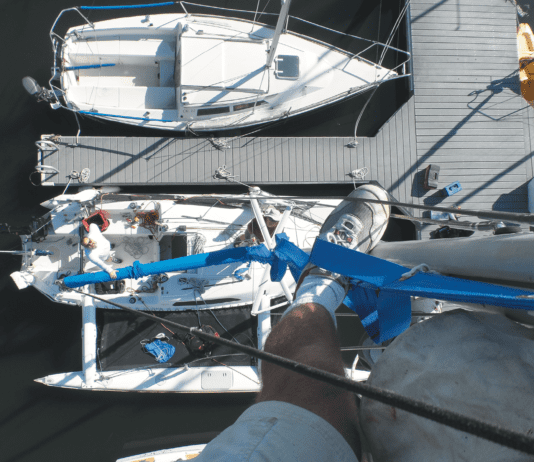

It also helps to minimize swaying motion if you raft up alongside a boat larger than your own. You always need to make sure the masts are staggered; if adjacent, and the boats roll, the rigging may be fouled.

As a matter of common courtesy, always walk forward of the mast when crossing over other boats- it helps preserve privacy.

For more advice and tips on everything from boat maintenance, navigation, racing tactics and cruise planning, purchase Bob Bonds The Handbook of Sailing. This classic contains 2,000 diagrams and photos enabling you to visualize every sailing procedure and maneuver; reflects the latest word on procedures, techniques, and equipment.

Riding Turn – Tip #1

From Bob Bonds - The Handbook of Sailing

Riding Turn

Sometimes, when winching, the coils of sheet on the barrel become crossed (known as a riding turn). This is usually a result of taking too many turns on the winch. It cannot be undone unless the tension is removed. Another line is first tied to the sheet, between the winch and the sheet lead, using a rolling hitch. The new line is then taken around a spare winch and wound in until it is taking the strain from the first winch and the riding turn can then be released. If you find that riding turns are occurring frequently, you should check the angle of then sheets to your winches.

For more hints and tips on sailing techniques for both the beginner and experienced sailor, purchase Bob Bonds The Handbook of Sailing from Practical Sailor.

Rigging – Tip #1

Early Asian-built sailboats had hardware and fittings especially tangs and turnbuckles that came from backyard foundries where little or no concern was given to the mechanical and chemical attributes of different alloys. Their approach to marine metals was based more upon how the metal looked, rather than how it would hold up under load. Voids and alloy problems in cast bronze and stainless rigging components became so widespread in the 1970s that many riggers told new owners to change the turnbuckles and toggles before they sailed their new boats. Even though the hardware looked like components made in the U.S. or Europe, the castings were far inferior. In that time period, Asian quality control during the alloying of non-ferrous metals was primitive at best, and the old adage "all that glitters isn't gold" certainly held true for silicon bronze, an alloy thats usually a superior choice for rigging hardware or submerged applications. Slight variation in the content and purity of the alloying metals will taint the recipe and change the metals mechanical as well as corrosion resistance characteristics, so quality control is imperative.

Little shortcuts can have serious ramifications, so the new owner of an older Asian-built boat would be smart to pursue a rigging hardware upgrade. Replacing the turnbuckles and toggles with U.S. or European product is money well spent. Older Chinese-built boats, in particular, have been plagued by unreliable metal components.

Circumnavigators and three-decade live-aboard cruisers Al and Beth Liggett had a box full of fasteners and hardware that died an early death aboard their able Perry-designed cruiser Sun Flower, which they had built in the Orient. Cyclic loading and working strains are expected to eventually wear out components, but the life span of a fastener or piece of hardware is drastically shortened if the metallurgy has been inconsistent.

This is anything but a xenophobic bias. Ive spoken with riggers across the country who have alluded to a disturbing trend associated with Chinese hardware and have shown me boxes filled with fractured turnbuckles, corroded tangs, and what-not the 60s well into the 80s when savvy builders started shipping U.S. and European hardware to China despite the cost.

For additional advice on rig inspections, purchase Boatowner's Illustrated Electrical Handbook from Practical Sailor.

Easing a Line on a Winch – Tip #1

Easing a Line on a Winch

It is important to know how to ease the tension of a sheet or halyard on a winch. The tail of the line is taken off the cleat but the tension must still be kept on it. One hand should then be placed on the turn of the line around the winch barrel and the heel of the hand used to feed the line around the barrel, as the other hand eases the tension on the line. It is most important that the fingers are kept well out of the way.

For more hints and tips on sailing techniques for both the beginner and experienced sailor, purchase Bob Bonds The Handbook of Sailing from Practical Sailor.

Sail Buying – Tip #1

Whats important about good sail shape? As one sailmaker likes to explain it, using poorly shaped or blown-out sails is like driving on bald tires. Youre pretty sure your car will take you from A to B, but you wont be able to turn well or stop promptly, and your enjoyment of driving will be diminished.

Before wading into these complex waters, its good to know some essential terminology and understand a few basic concepts involved in sailmaking, so heres a quick primer.

Upwind sails are characteristically built in two ways, either by crosscut or composite construction (often referred to as laminated sails). Crosscut sails are essentially built of woven polyester fabric (most often know by DuPonts trademarked name, Dacron) where the panels of cloth run from the luff of the sail to the leech. Composite construction can be achieved in several ways, but the objective is to align the load-bearing fibers of the main structural material (often referred to as the scrim) with the primary load paths of the sail. Doing this requires layering different materials, since mere woven polyester, with its strength primarily in the fill (or short axis) direction of the weave, won't suffice for more than modest loads and thus isn't sufficient in composite construction for sails that will be hoisted on boats over 20 feet.

For more advice and recommendations on sails - what to buy, carry and use, purchase Practical Sailor's downloadable ebook A LOOK AT SAILS, PART TWO: Headsails & Furling Gear.

Also, check out the complete 3 volume series, PRACTICAL SAILOR'S A LOOK AT SAILS - Complete Series at a price that gives you one ebook free when you buy the other two.

Sail Buying – Tip #2

Sailmakers around the world have been printing up new business cards even though they continue to work for the same franchised lofts. Their new cards have swapped job description titles from sailmaker to sail designer, a result thats partly due to the proven value of computer-aided design and partly due to a growing trend toward sending sailmaking overseas. Like so many other industries, sailmakers have responded to the lure of lower labor rates and the growth in high-tech manufacturing skills in Asia. Many of the big-name lofts have curtailed much of their domestic sail production and instead focus on building each customer a virtual sail in their local loft, digitizing carefully made measurements, and electronically forwarding the data to a mega loft on the other side of the globe.

Sailmaking success continues to be measured in units of satisfied customers, and despite the remote location of the loft floor, this globalized approach seems to present a viable model, both from the perspective of the consumer and the business. Its true that not as much dialogue can take place between the loft salesman, sailmaker, and skipper - a kind of collaboration that in the past led to some important decision making and genuine brand allegiance. But a capable sail designer can still deliver the goods. To do so, he must address three critical points: capture accurate initial measurements, use sophisticated design software to customize sails for the specific boat, and match the design work with the sailing preference and crew skill level.

Fortunately for those who savor the working relationship that they have had in the past with the favorite salesman/sailmaker, there are still smaller independent lofts where sewing machines continue to whir away and where the sailmaker who built your sails is still willing to join you for a sea trial. Such lofts are like independent hardware stores - an endangered species, something well all certainly miss when the full effect of centralized sailmaking take hold. Some of the independents will survive on the repair work that the sailing season generates, but many see the handwriting on the wall and are turning production over to wholesalers such as China Sails Factory in Guang Dong Province, Southern China.

For more advice and recommendations on sails - what to buy, carry and use, purchase Practical Sailor's downloadable ebook A LOOK AT SAILS, PART TWO: Headsails & Furling Gear.

Also, check out the complete 3 volume series, PRACTICAL SAILOR'S A LOOK AT SAILS - Complete Series at a price that gives you one ebook free when you buy the other two.

Sail Buying – Tip #3

Sails are a fascinating engineering statement, and when all is said and done, whats sought after is the lightest material possible that will neither stretch nor tear as it withstands the ravages of wind-induced pressure, vessel righting movement, and harassment from sunlight, chafe, atmospheric deposition, and other deteriorating effects. Thanks to modern chemistry, cotton cloth lies well astern, but for several important reasons, even after 50 years, Dacron has yet to be destined for the junk pile. The pros we interviewed for this article remained surprisingly bullish on Dacron, and it caused us to do some research into why the modest polyester fiber still has such a following.

The answer has to do with cost and chemistry, or more specifically, the crossover point where features such as tenacity, flexural endurance, UV stability and resistance to chemical deterioration stack up on a cost-per-square-yard basis. For those looking to stretch their sail buying dollars, Dacron delivers. But the real value lies in tightly woven high-yarn-count premium Dacron, a material that hold its shape and will keep cruisers happy for the long haul.

For more advice and recommendations on sails - what to buy, carry and use, purchase Practical Sailor's downloadable ebook A LOOK AT SAILS, PART TWO: Headsails & Furling Gear.

Also, check out the complete 3 volume series, PRACTICAL SAILOR'S A LOOK AT SAILS - Complete Series at a price that gives you one ebook free when you buy the other two.

Sail Maintenance – Tip #1

From Bob Bonds The Handbook of Sailing

Most people are not sufficiently expert to be able to carry out any but the most minor repairs to their sails and it is better not to attempt to mend sails yourself. They should be sent back to the manufacturer or to a professional sail repairer. However, it is essential to learn how to spot signs of wear so that you can deal with it before it gets worse. The easiest way to inspect your sails is to lay them out flat on an even clean surface and work around the edges and over the belly of the sail. Pay special attention to the points where the sail is attached to the spars and rigging.

The Fead

Examine the headboard (the reinforced part at the head of the sail) and make sure that the rivets are in place and that the stitching is not weak anywhere. The latter may well wear around the head and you will need to check the reinforced patches in this area.

The Tack

The tack is subjected to a great deal of strain and can distort. If the stitching breaks the whole sail will become misshapen. On a main sail, look for signs of wear on the bolt line (rope edging) where it rubs on the boom and for damage to the stitching on it.

The Clew

The clew is subjected to the same type of wear as the tack, but on headsails is particularly vulnerable to chafe against the standing rigging.

The Luff

On a mainsail, check that all the slugs are properly attached and not broken and that the reefing cringle is not distorted. Look out for chafe along the bolt line on a mainsail and for strands of broken wire on a headsail luff. The hanks on a headsail must be firmly attached and free from any corrosion.

The Foot

On a mainsail with a roller reefing system, check for signs of chafe where it has been rolled around the boom. If there are slab reefing points or eyelets check that these are not pulled or torn.

The Leech

Examine the battern pockets for damaged stitching and if there are any leech line attachments make sure they are in position. Genoa leeches on cruising boats are particularly vulnerable to chafe against the lifelines or shrouds.

General Points

Always be alert to the possibility of deterioration of the fabric due to sunlight. If the cloth is thin or brittle over a small area it can be patched, but with larger areas the sail should be replaced.

For more advice and tips on everything from boat maintenance, navigation, racing tactics and cruise planning, purchase Bob Bonds The Handbook of Sailing. This classic contains 2,000 diagrams and photos enabling you to visualize every sailing procedure and maneuver; reflects the latest word on procedures, techniques, and equipment.